Selecting the right triaxial latex membrane can seem daunting at first. I’ve spent countless hours figuring out the best options to ensure accurate and reliable geotechnical tests.

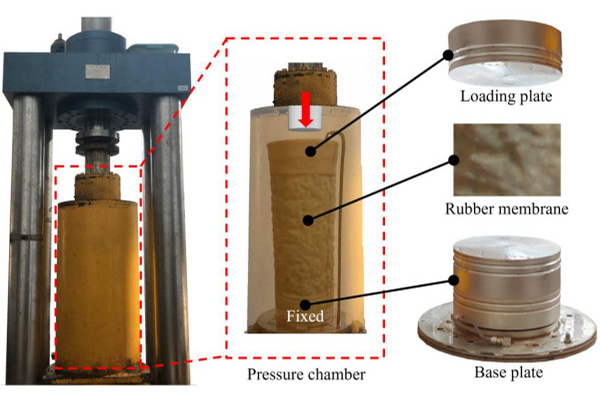

Choosing the appropriate triaxial latex membrane is essential for precise geotechnical testing. Key factors include size, thickness, radius ratio, and soil particle size distribution. Making informed decisions on these aspects ensures the integrity and consistency of your test results.

Let’s dive into the critical factors you need to consider when selecting triaxial latex membranes.

How to choice size?

Determining the correct size of your triaxial latex membrane is fundamental for effective testing.

Selecting the right size ensures that the membrane fits snugly around your soil sample and triaxial cell. A properly sized membrane prevents leaks and maintains consistent pressure during tests, which is crucial for obtaining accurate results.

Diving Deeper into Choosing the Right Size

Size selection isn’t just about matching dimensions; it’s about ensuring compatibility and functionality. Here are some detailed considerations:

-

Triaxial Cell Dimensions: Accurately measure the diameter and height of your triaxial cell. The membrane should cover the entire height and wrap around the diameter without excess material that could interfere with the testing process.

-

Soil Sample Size: Ensure the membrane can accommodate the soil sample size, allowing for any expansion or contraction during pressure application. A membrane that’s too tight might tear, while one that’s too loose could lead to leaks.

-

Installation Ease: A correctly sized membrane is easier to install, reducing the risk of wrinkles or folds that can compromise the seal. This also minimizes setup time and potential errors during the testing process.

-

Standard vs. Custom Sizes: While standard sizes are available for common triaxial cells, custom-sized membranes might be necessary for unique experimental setups or specialized equipment.

| Consideration | Importance | Impact on Test Results |

|---|---|---|

| Cell Dimensions | Ensures complete coverage | Prevents leaks and sample disturbance |

| Sample Size | Accommodates soil behavior under stress | Maintains test integrity |

| Installation Ease | Reduces setup time and potential errors | Enhances reliability |

| Standard vs. Custom | Flexibility for unique applications | Ensures compatibility and precision |

By carefully measuring and selecting the appropriate size, you set the foundation for reliable and repeatable geotechnical tests.

How to choice thickness?

The thickness of your latex membrane plays a pivotal role in its performance and durability during triaxial tests.

Choosing the right thickness is crucial for membrane longevity and resistance to tearing under high pressures. Thicker membranes offer greater durability but may reduce flexibility, while thinner membranes provide better flexibility but are more prone to damage.

Understanding Membrane Thickness

Selecting the appropriate thickness involves balancing durability and flexibility based on your testing requirements:

-

Pressure Conditions: Higher test pressures necessitate thicker membranes to withstand the increased stress without rupturing. For instance, membranes with a thickness of 0.3 mm are suitable for medium pressure ranges, while those at 0.4 mm are ideal for high-pressure tests.

-

Flexibility Needs: Thinner membranes, such as 0.2 mm, offer greater flexibility, making them easier to handle and install, especially with irregularly shaped soil samples. This flexibility can be advantageous in tests requiring precise adjustments.

-

Durability and Reusability: Thicker membranes tend to be more durable and can be reused multiple times, providing better value for your investment. They are less likely to tear during repeated use, ensuring consistent performance across tests.

-

Material Composition: The type of latex used can influence the optimal thickness. Some synthetic latexes may offer higher tensile strength, allowing for thinner membranes without compromising durability.

Practical Insights

In my experience, finding the right balance between thickness and flexibility is key. For high-pressure tests, a membrane thickness of 0.3 mm has proven reliable, providing the necessary strength without sacrificing too much flexibility. Conversely, for lower pressure tests, a thinner membrane like 0.2 mm offers ease of use and sufficient durability.

| Thickness (mm) | Flexibility | Durability | Suitable Pressure Range |

|---|---|---|---|

| 0.2 | High | Low | Up to 100 kPa |

| 0.3 | Moderate | High | 100-300 kPa |

| 0.4 | Low | Very High | Above 300 kPa |

Selecting the appropriate thickness based on your specific testing conditions ensures that your membranes perform reliably, enhancing the accuracy of your geotechnical assessments.

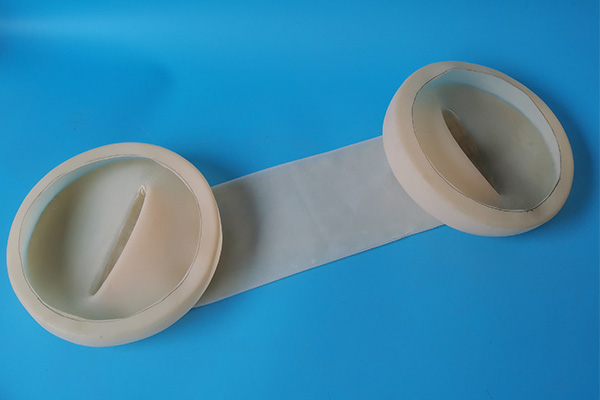

How to choice radius ratio?

The radius ratio of a latex membrane influences how it conforms to the soil sample and interacts with the triaxial cell.

Choosing the appropriate radius ratio ensures that the membrane can evenly distribute pressure around the sample, preventing uneven stress and potential sample deformation. A well-chosen radius ratio enhances the accuracy and consistency of your test results.

Delving into Radius Ratio Selection

Understanding the implications of different radius ratios helps in selecting the optimal membrane for your tests:

-

Sample Geometry: The shape and size of your soil sample determine the ideal radius ratio. For example, spherical samples may require a different radius ratio compared to cylindrical ones to ensure uniform coverage.

-

Membrane Stretchability: A membrane with higher elasticity can accommodate a wider range of radius ratios without losing integrity. This is particularly important for tests involving samples that may change shape under stress.

-

Testing Standards: Adhering to ASTM or other relevant standards may specify certain radius ratios for specific test types. Ensuring compliance with these standards is crucial for the validity of your test results.

-

Practical Application: In my lab, adjusting the radius ratio based on preliminary tests helped achieve more consistent and reliable results. For irregular samples, a slightly higher radius ratio provided better pressure distribution without overstressing the membrane.

Detailed Considerations

-

Uniform Pressure Distribution: A correct radius ratio ensures that the membrane maintains even pressure around the sample, avoiding hotspots that could skew results. This uniformity is essential for accurate stress-strain measurements.

-

Ease of Installation: Membranes with suitable radius ratios are easier to install without excessive stretching or slack. This reduces the risk of wrinkles or folds that can lead to leaks or uneven pressure application.

-

Compatibility with Equipment: Ensure that the chosen radius ratio aligns with your triaxial cell design and operational parameters. Compatibility ensures that the membrane functions as intended without compromising the testing process.

| Radius Ratio | Sample Shape Compatibility | Pressure Distribution | Installation Ease |

|---|---|---|---|

| 1:1 | Perfect spheres | Uniform | High |

| 1.2:1 | Slightly irregular shapes | Mostly uniform | Moderate |

| 1.5:1 | Highly irregular shapes | Potentially uneven | Low |

By carefully selecting the radius ratio, you can enhance the performance of your triaxial tests, ensuring that the membrane supports accurate and reliable measurements.

How to choice according to soil particle size distribution

Soil particle size distribution is a critical factor in determining the appropriate latex membrane for your triaxial tests.

Choosing a membrane based on soil particle size distribution ensures that the membrane can effectively contain and interact with the sample without causing damage or interference. This leads to more accurate simulation of real-world conditions and reliable test outcomes.

Matching Membrane Choice to Soil Particle Size

Understanding the relationship between soil particle size and membrane selection is key to maintaining test integrity:

-

Particle Size Range: Larger particles, such as gravel, require membranes with higher tear resistance to prevent punctures. Thicker membranes are often necessary to withstand the abrasive nature of these particles. Finer particles, like silts and clays, may require more flexible membranes to accommodate moisture and prevent tearing.

-

Soil Type: Different soil types interact uniquely with membranes. For instance, sandy soils are more abrasive and may demand membranes with smoother surfaces to reduce wear, while clayey soils hold moisture better, requiring membranes that resist tearing under moist conditions.

-

Membrane Surface Texture: A smoother membrane surface can help prevent particles from sticking or clogging, which is particularly important for fine-grained soils. Textured membranes might be beneficial for certain soil types to enhance containment and reduce slippage.

-

Compatibility with Testing Protocols: Align membrane selection with the specific requirements of your testing standards and protocols. This ensures that the membrane’s properties support the intended testing conditions and methodologies.

Practical Application

In my experience, selecting membranes based on soil particle size distribution significantly impacts the reliability of test results. For example, when working with sandy soils, I opted for membranes with a thickness of 0.3 mm and a smooth surface texture to resist abrasion and prevent particle interference. Conversely, for clayey soils, a thinner, more flexible membrane was necessary to accommodate the moisture and reduce the risk of tearing.

| Soil Type | Particle Size Range | Recommended Membrane Thickness | Surface Texture |

|---|---|---|---|

| Sandy | 0.05 – 2 mm | 0.3 mm | Smooth |

| Clayey | <0.05 mm | 0.2 mm | Textured |

| Silty | 0.002 – 0.05 mm | 0.25 mm | Semi-smooth |

| Gravelly | 2 – 20 mm | 0.4 mm | Rough |

By tailoring your membrane choice to the specific soil particle size distribution, you enhance the accuracy and consistency of your triaxial tests, ensuring that your results are both reliable and representative of real-world conditions.

Conclusion

Selecting the right triaxial latex membrane involves careful consideration of size, thickness, radius ratio, and soil particle size distribution. By understanding and balancing these factors, you can ensure your geotechnical tests are both accurate and reliable.

One Response