Asphalt Mix Design Methods Compared: Hveem, Marshall, Superpave, and BMD

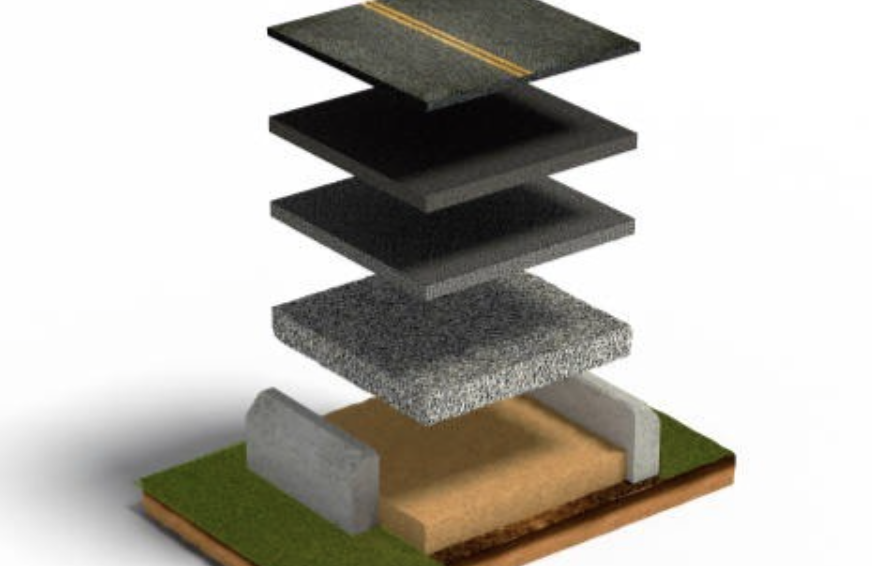

Choosing the right asphalt mix design method can significantly impact pavement performance, durability, and cost. Over time, several design philosophies have emerged—each reflecting a different balance of lab testing, field experience, and performance goals. In this article, we compare the four major asphalt mix design methods: Hveem, Marshall, Superpave, and Balanced Mix Design (BMD).

Hveem Method: Stability Through Empirical Control

Developed in California in the 1920s, the Hveem Method1 focuses on measuring stability using empirical data2. It uses a device called the stabilometer3 to evaluate the resistance of compacted asphalt mixtures to lateral movement under pressure.

Key Features:

- Relies on a kneading compactor for specimen preparation.

- Evaluates stability (resistance to deformation) and cohesion.

- Ideal for dense-graded mixes in moderate climates.

| Characteristic | Hveem Method |

|---|---|

| Compaction | Kneading |

| Stability Test | Stabilometer |

| Climate Suitability | Mild to moderate |

Although less common today, the Hveem method remains in use in some western U.S. states for localized mix design standards.

Marshall Method: Widely Adopted Legacy Standard

The Marshall Method4, developed during WWII by Bruce Marshall, became the standard mix design method for many decades, especially in the U.S. and Asia. It combines volumetric analysis with a simple load/stability test.

Key Features:

- Uses an impact hammer5 for sample compaction.

- Measures Marshall Stability6 and Flow to determine optimal binder content.

- Common in airport, highway, and municipal projects.

| Characteristic | Marshall Method |

|---|---|

| Compaction | Hammer (75–50 blows) |

| Key Measurements | Stability, Flow |

| Strengths | Simplicity, standardization |

While still widely used, it lacks direct performance evaluation, which limits its predictive accuracy in evolving climate and traffic conditions.

Superpave: Performance-Based Innovation

Introduced in the 1990s under the Strategic Highway Research Program (SHRP), Superpave (SUperior PERforming Asphalt PAVEments) aims to match asphalt design to real-world conditions. It is performance-based7 and includes more rigorous specifications.

Key Features:

- Incorporates climate and traffic data8 into binder selection.

- Uses a gyratory compactor for specimen preparation.

- Measures volumetric properties like VMA, VFA, and air voids.

| Characteristic | Superpave Method |

|---|---|

| Focus | Performance-based |

| Equipment | Superpave Gyratory Compactor |

| Innovation | Climate- and traffic-specific |

Superpave is the current standard for U.S. federal and state highway projects, offering greater flexibility and durability for high-performance pavements.

Balanced Mix Design (BMD): Bridging Volumetrics and Performance

Balanced Mix Design (BMD) is an emerging approach that seeks to combine traditional volumetric mix design with performance testing to create a more durable, cost-effective asphalt mixture.

Key Features:

- Incorporates both rutting and cracking performance tests.

- Uses existing Superpave or Marshall volumetrics as a baseline.

- Allows greater innovation in materials and mix design.

| Characteristic | Balanced Mix Design (BMD) |

|---|---|

| Core Approach | Balance performance and volumetrics |

| Flexibility | High—supports innovative mixes |

| Popularity | Rapidly growing in state DOTs |

BMD is often viewed as the next evolution of asphalt mix design—especially as sustainability and long-term performance become central goals.

Conclusion

Each asphalt mix design method—Hveem, Marshall, Superpave, and BMD—offers unique advantages depending on your goals, resources, and project specifications. While legacy methods like Hveem and Marshall focus on simplicity and field-proven stability, Superpave introduces climate-specific design precision. BMD goes a step further, integrating lab performance testing to help engineers design longer-lasting, more resilient pavements in a cost-effective way.

-

Explore this link to understand the Hveem Method’s significance in asphalt stability testing and its applications. ↩

-

This resource will provide insights into the empirical methods used for measuring stability in asphalt mixtures, enhancing your knowledge. ↩

-

Learn about the stabilometer’s role in evaluating asphalt mixtures, crucial for understanding its effectiveness in construction. ↩

-

Explore this link to understand the significance and application of the Marshall Method in asphalt mix design, especially its historical context and impact. ↩

-

Discover how the impact hammer is used in asphalt compaction, enhancing the quality and durability of road surfaces. ↩

-

Learn about the measurement of Marshall Stability, a crucial aspect of asphalt testing that ensures quality and performance in road construction. ↩

-

Learn about performance-based approaches in construction and how they enhance project outcomes. ↩

-

Discover the importance of climate and traffic data in optimizing asphalt design for durability and safety. ↩