I’ve learned this the fun way: membrane shape1 quietly decides how clean your data looks.

Standard membranes work for most tests, but custom shapes2 solve tricky setups, reduce leaks, and improve alignment—especially for ports, rough soils, and non-standard geometries.

Here’s a clear way to choose without drama.

What are the features and typical applications of standard membranes3?

They’re simple, fast, and dependable for day-to-day triaxial work4.

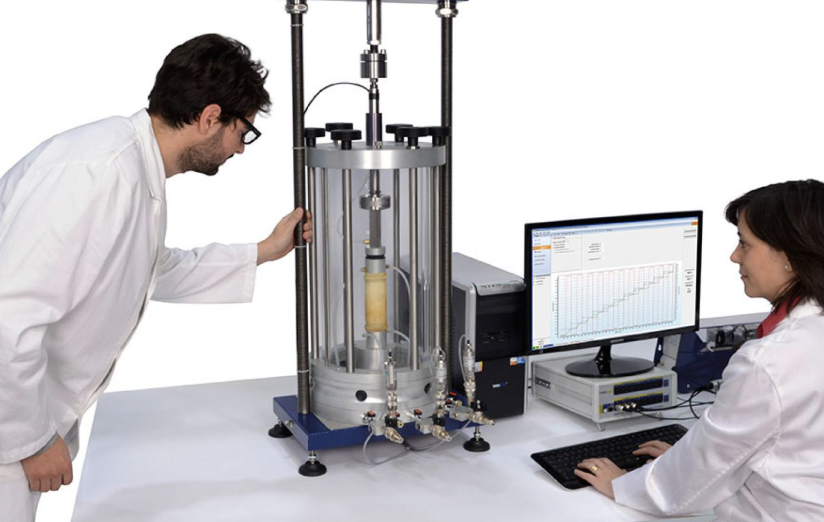

Use standard straight-tube membranes for routine UU, CU, and CD tests where specimens are uniform cylinders and end hardware is conventional.

Dive deeper: why “plain” works most of the time

Most lab specimens are cylinders with L/D ≈ 2.0–2.5. Standard membranes fit this world well: quick to mount, easy to stock, and predictable in stretch. For clays and silts, I pick thin to medium walls5 to keep volume-change signals honest. For sands or higher σ₃, I step up thickness for durability. When hardware is standard—flat caps, typical porous stones—there’s no reason to complicate the setup.

That said, even with standard shapes I still check ID ≈ OD, run a quick bubble test, and keep two thickness grades per diameter. These tiny habits avoid false dilation from wrinkles and prevent B-value headaches in CU tests. If a specimen is slightly oval or tapered, I re-trim rather than “force the fit.” Reliable boredom beats clever fixes.

To keep ordering easy, I maintain a short matrix (diameter × soil type × σ₃) and mark the default wall grade. It keeps the team aligned and reduces last-minute guessing: [standard size matrix](https://www.sciencedirect.com/science/article/pii/S0376738822000606)6. For a refresher on wall/thickness effects, my pocket card helps junior techs choose fast: [thickness quick card](https://www.sigmaaldrich.com/US/en/products/clinical-diagnostics/lateral-flow-membranes?srsltid=AfmBOor4XPq_8Bs9jBxceH7_oex6fhQlxcdkcmyxbVPXoIxDxudYMi)7.

| Use case | My default pick | Why |

|---|---|---|

| UU clay (Ø 38–50) | Medium wall | Seals fast; fewer reruns |

| CU clay/silt | Thin–medium | Better u-response; B ≥ 0.95 |

| CD sand | Thin if smooth; medium if angular | Volume fidelity vs durability |

When and why should I consider custom-shaped membranes?

When geometry or plumbing breaks the “clean cylinder” rule.

Choose custom shapes2 for ported specimens8, flanged caps, irregular diameters, high-abrasion sands, or when alignment and sealing9 are hard with standard tubes.

Dive deeper: where custom saves the day (200+ words)

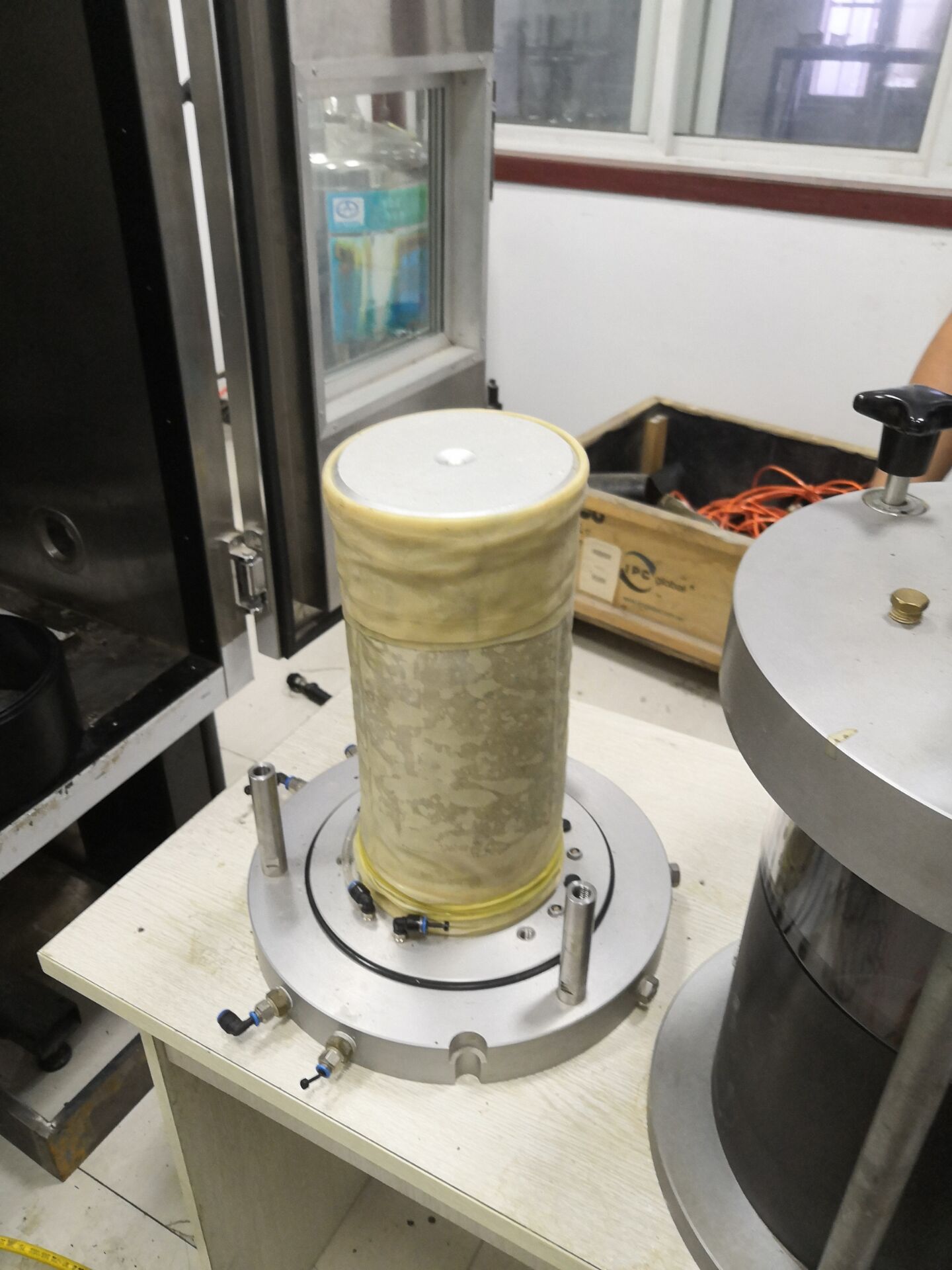

Custom membranes shine when the specimen or hardware is not a simple cylinder. Think ported samples for local strain/pore-pressure probes, flanged ends to manage edge friction, or stepped diameters (e.g., resin jackets, collars). A custom flanged lip can seat neatly under a retaining ring, reducing slip and improving repeatability. For abrasive or angular soils, thicker wall blends or chlorinated latex reduce pinholes.

Another win is alignment. If your test adds sensors, cables, or tubing, a custom pre-formed port keeps penetrations tight and repeatable, which protects u-measurements and avoids sneaky leaks. Transparent custom membranes help me visually confirm bubbles around ports before consolidation, cutting setup time later: ported mounting guide.

Finally, customs can reduce setup variability10 across operators. When a membrane “wants” to sit exactly where you need it, fewer hands-on adjustments mean smoother q–ε, cleaner volume curves, and tighter scatter in φ′/c′. The trade-off is cost and lead time, so I reserve customs for repeated campaigns or research programs where the same geometry runs many times: custom ROI notes.

| Challenge | Custom feature | Benefit |

|---|---|---|

| Ported specimens | Pre-formed port | Leak-tight u-lines |

| Edge slippage | Flanged skirt | Better end restraint control |

| Abrasive grains | Tougher blend | Fewer pinholes |

| Irregular Ø | Tapered body | Fewer folds/wrinkles |

How do cost, performance, and lab efficiency compare?

Look beyond unit price—count reruns and technician time.

Standard membranes are cheaper per piece; customs cut variability, mounting time, and rework in complex setups—often lowering total cost per valid test.

Dive deeper: total cost of quality11 for membranes

I use a simple lens: Cost = Material + Time + Rework + Risk. Standard membranes win on material. But when geometry is tricky—ports, collars, odd diameters—standard shapes can inflate time (careful hand-fitting), rework (leaks, folds), and risk (scatter in u-response or volume change). Customs add material cost but often reduce the other three dramatically.

In a CU program with local pore-pressure ports, our switch to custom ported membranes12 cut average mounting time by 25–35% and raised first-pass B ≥ 0.95 rates. In CD tests on angular sand at high σ₃, a thicker custom with a slightly stiffer blend lowered mid-height pinholes to near zero and stabilized volume curves. The spreadsheet told the story: fewer repeats, tighter parameters, faster reporting: TCQ worksheet.

My rule: if I’ll run ≥ 20 similar non-standard tests, I model a custom. Below that, I try to stay standard and improve SOPs—better deburring, transparent walls, and tighter ID bands. Either way, I document time, failure modes, and scatter so the next decision is data-driven: decision checklist.

| Scenario | Standard | Custom |

|---|---|---|

| Routine UU/CU/CD | ✓ Low cost | Overkill |

| Ported/local strain | Fiddly, leak-prone | ✓ Faster, tighter u |

| High σ₃ angular sands | Tears possible | ✓ Tougher wall |

| Repeated research runs | Operator-dependent | ✓ Consistent geometry |

How does HOWDY support custom membrane solutions for complex soil tests?

We build to your drawing, keep it simple, and stay B2B-only.

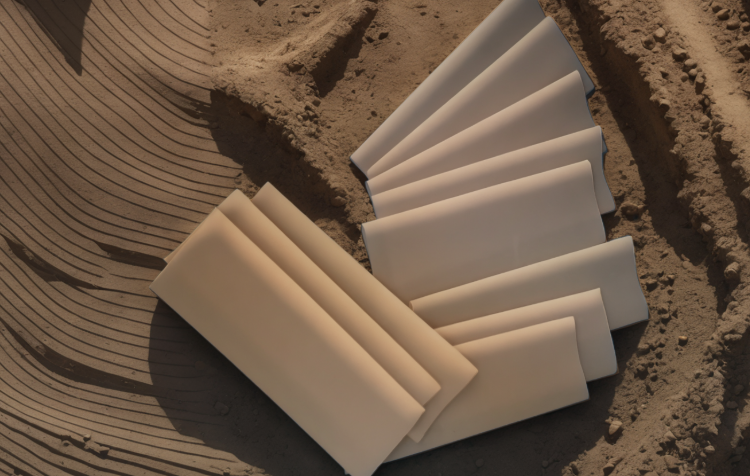

At HOWDY (China), I offer standard and custom latex membranes13—straight, flanged, ported, or transparent—sized to your Ø with traceable lots and stable wall tolerances.

Dive deeper: our practical approach

I keep the process lean: you send specimens Ø/height, hardware sketches, and any port locations. My design team proposes 1–2 shapes: usually a snug ID with either a flanged lip or clean port collars. We confirm thickness by soil type and σ₃ targets—thin/transparent for clay CD fidelity; medium/thicker or chlorinated for sands and higher pressures. Every batch ships with lot labels and stable thickness tolerance targets, so your data doesn’t drift box-to-box: request form.

Because we’re factory-side and wholesale-only, MOQs are reasonable for labs, universities, and large buyers, especially in Germany, France, UK, Spain, Italy, Poland, USA, and Australia. If you want to try customs without risk, we usually prototype a small set first. My personal goal is simple: predictable mounting14, fewer leaks, cleaner curves. Advice is free—“latex membrane free” is our friendly promise: data first, sales second: www.latexmembrane.com.

| Option | What we offer | Typical use |

|---|---|---|

| Standard straight | Multiple IDs/thicknesses | Routine UU/CU/CD |

| Transparent wall | Visual wrinkle check | CD volume fidelity |

| Flanged lip | Controlled end restraint | Edge-slip control |

| Ported body | Tight u-line integration | CU with local sensors |

Conclusion

Use standard for simple cylinders; choose custom when geometry, ports, or grains raise risk—let fit and repeatability lead.

-

Understanding how membrane shape affects data quality can enhance your testing accuracy. ↩

-

Explore the benefits of custom shapes to improve your testing setups and reduce leaks. ↩ ↩

-

Learn why standard membranes are often the go-to choice for routine tests. ↩

-

Gain insights into triaxial work and its significance in geotechnical engineering. ↩

-

Discover how wall thickness impacts the accuracy of volume-change signals. ↩

-

A standard size matrix can streamline your ordering process and improve efficiency. ↩

-

A thickness quick card can assist junior techs in making fast, informed choices. ↩

-

Learn about ported specimens and their role in enhancing measurement accuracy. ↩

-

Explore the critical role of alignment and sealing in achieving reliable test results. ↩

-

Reducing setup variability can lead to more consistent and reliable test outcomes. ↩

-

Understanding the total cost of quality can help you make better procurement decisions. ↩

-

Custom ported membranes can significantly improve testing efficiency and accuracy. ↩

-

Explore the various types of latex membranes to find the best fit for your testing needs. ↩

-

Predictable mounting is key to reducing errors and improving test reliability. ↩