How Pneumatic Pressure Controllers Improve Accuracy in Triaxial Soil Testing

Tight pressure control turns shaky triaxial curves into clean stories. I’ve watched it rescue whole projects overnight.

Pneumatic pressure controllers deliver precise, stable cell and back-pressure control with fast, low-overshoot ramps. That keeps effective stress honest, speeds saturation, and makes CU/CD stress paths reproducible.

Let’s talk pressure accuracy, stress-path control, B-checks, and why modern labs depend on pneumatics.

Why Does Pressure Accuracy Matter in Triaxial Testing?

If cell or back pressure wobbles, effective stress1 wanders. Then strength, stiffness, and pore-pressure plots stop matching real soil behavior.

Accurate, stable pressures stop fake stiffness and drift. With pneumatics2, you hit targets quickly, hold them quietly, and trust every point on the curve.

One night I chased a “mystery strength gain” in clay. The soil wasn’t stronger; the pressure was unstable. The old regulator overshot by a few kilopascals, dipped, then settled. That tiny dance inflated stiffness and distorted Δu. After we switched to a pneumatic controller with closed-loop feedback, the ramp hit setpoint without drama, and the curve relaxed into the shape I expected.

What pressure accuracy fixes

- Fake stiffness from micro-overshoot. Air behaves like a spring when pressure swings; smooth control removes that illusion.

- Drift during holds. Good regulators keep σ₃ and back pressure steady, so effective stress (σ′) stays where you think it is.

- Noisy permeability and volume change. Stable heads make k and εᵥ cleaner.

Quick comparison table

| Item | Old manual/weight system | Pneumatic controller |

|---|---|---|

| Ramp behavior | Overshoot/undershoot likely | Fast, low-overshoot ramps |

| Hold stability | Sensitive to room/air bumps | Active feedback, steady holds |

| Fine setpoint steps | Coarse | Sub-kPa resolution (device-dependent) |

| Automation | Minimal | Programmable profiles & logs |

Helpful starter kits: pressure ramp SOP template • hold-stability checklist guide • noise troubleshooting map sheet

How Do Pneumatic Controllers Enhance Stress Path Control?

Stress paths are choreography. Pneumatics let me coordinate cell and back pressure so p′ and q move exactly how the test demands.

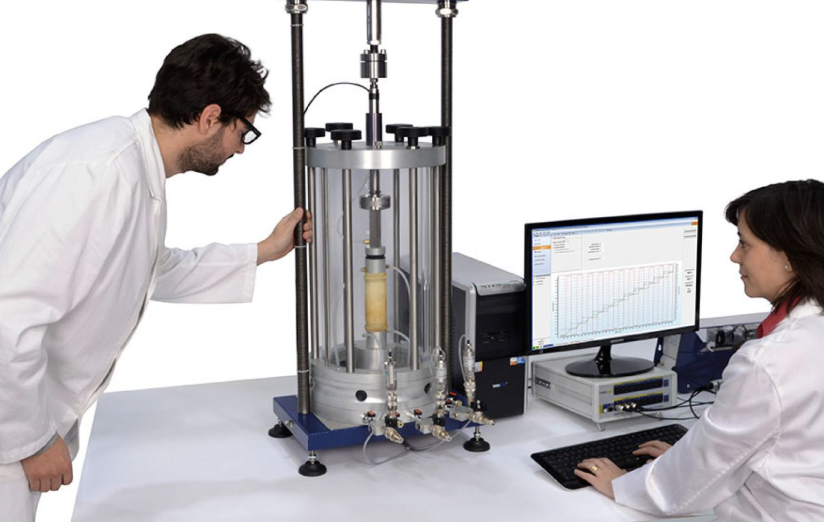

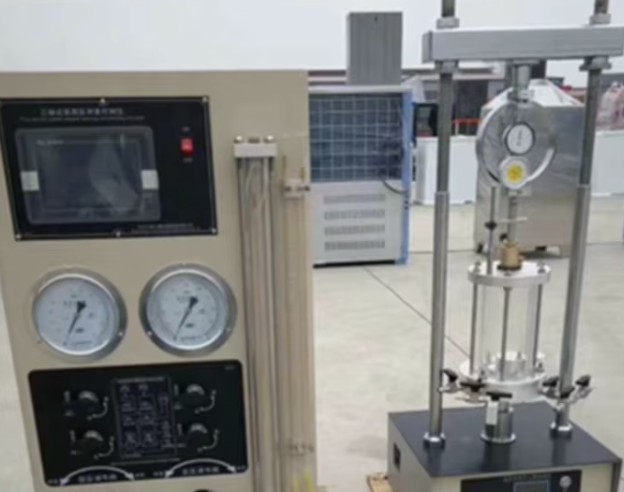

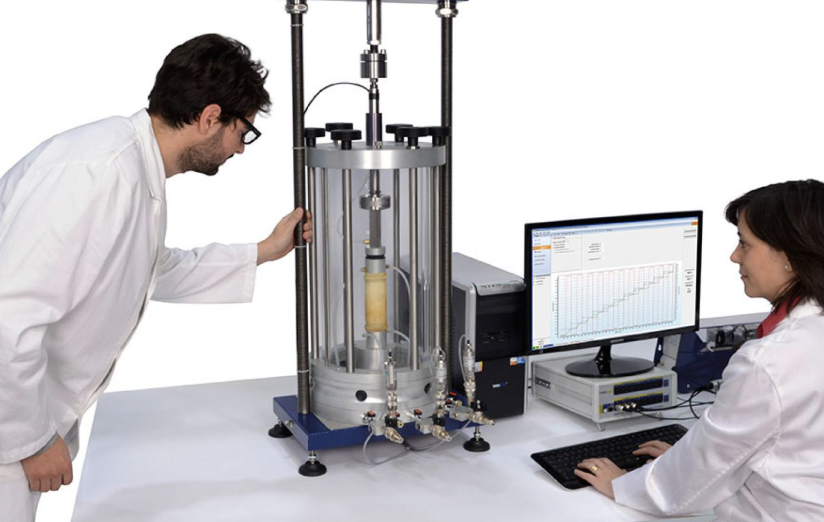

Closed-loop pneumatics execute constant-p′, constant-q3, K₀, and custom paths with synchronized channels—less lag, fewer corrections, tighter repeatability.

I think of the controller as a calm partner in a duet: one channel sets σ₃, another holds or changes back pressure, and the load frame manages axial stress/strain. With good pneumatics, those moves happen together. For constant p′ (mean effective stress), the controller raises cell pressure while adjusting back pressure so p′ = (σ₁′ + 2σ₃′)/3 stays fixed as you change q. For K₀ consolidation, it nudges confinement to track lateral stress without over-shooting. In cyclic programs, rapid but controlled micro-steps prevent pore-pressure shocks that would bias Ru buildup.

Patterns I run a lot

- Constant p′ shearing: tiny, synchronized steps on σ₃ and u_b to lock p′. p′ recipe

- Stress-controlled CU: ramp σ₃ to target, freeze, then undrained shear. CU script

- CD drainage studies: precise low heads for long holds. CD head plan

- Cyclic paths: waveform tables with soft edges (no spikes). Cyclic deck

Little rules that keep paths clean

- Align sensor calibration before any profile. Cal plan

- Use pre-ramp previews to catch limits or leaks. Preview check

- Log every setpoint and achieved value. Audit log

What Role Do Pneumatic Controllers Play in B-Value Verification?

B-checks should be boring. Precise pressure pulses make them that way.

Pneumatic controllers deliver small, repeatable cell-pressure pulses and quiet holds—so B = Δu/Δσ₃ is clean, stable, and believable.

B-value4 tells me if pores are water-filled. To measure it, I apply a tiny Δσ₃ and read the immediate Δu. With a pneumatic controller, that pulse is crisp and repeatable—no lazy ramps, no bouncing. If B drifts between two identical pulses, I suspect stones, valves, or a leak, not the actuator. That clarity saves time. In one program, B hovered around 0.93 with a wobbly manual pulse. Switching to a scripted +20 kPa pneumatic pulse gave 0.98 twice in a row—same specimen, better actuation.

A simple B-check routine I trust

- Hold near-zero effective stress, steady temperature.

- Fire a small, fast +Δσ₃ pulse (e.g., +20 kPa).

- Read immediate Δu; compute B.

- Repeat once; values should match within noise.

Targets & actions

| B range | Meaning | Action |

|---|---|---|

| ≥ 0.98 | Excellent | Proceed to consolidation/shear |

| 0.95–0.98 | Good | Proceed; monitor drift |

| 0.90–0.95 | Borderline | Extend holds; re-flush stones |

| < 0.90 | Not ready | Re-saturate; chase leaks |

Tools: pulse card one-pager • B-tracker sheet • stone care guide

Why Are Pneumatic Controllers Essential for Modern Geotechnical Labs?

Modern labs live on speed, traceability, and safety. Pneumatics deliver all three without oil mess or manual fiddling.

They automate profiles, reduce re-tests, capture full audit trails, and cut contamination risks—raising throughput and confidence for CU/CD, permeability, and cyclic programs.

When buyers ask me what actually moves the needle, I say: fewer retests, cleaner plots, better stories for design. Pneumatic controllers5 help on every front. Throughput: scripted ramps and holds mean technicians run more specimens with fewer interruptions. Quality: every setpoint and reading gets logged, so you can defend results months later. Safety and cleanliness: no oil columns, fewer manual tweaks at pressure, less chance of contamination in flexible-wall permeability rigs. Integration: digital controllers6 talk to DAQ, so σ₃, back pressure, pore pressure, and axial data live in one time base. That’s gold when reconciling Δu spikes or odd volumetrics. Finally, training gets easier: new techs follow clear profiles that feel the same every time. I’ve watched a team go from “lots of scatter” to “tight overlays” in two weeks—mostly by letting pneumatics handle the choreography and keeping humans focused on specimen prep.

Lab adoption checklist

- Map your common profiles (CU, CD, constant p′, cyclic). Profile library

- Define pass/fail bands for holds and ramps. QA bands

- Link controller logs into DAQ exports. Data stitcher

- Set a weekly quick-cal and leak test. Weekly ritual

Snapshot table: why labs switch

| Benefit | What you get |

|---|---|

| Fewer retests | Stable ramps/holds reduce borderline runs |

| Cleaner audits | Automatic logs of setpoints & achieved values |

| Safer workflows | No heavy weights or oil handling |

| Faster programs | Script once, reuse across specimens |

Conclusion

Stable pressure, clean pulses, honest stress paths—pneumatics make triaxial data calm, clear, and ready for design.

-

Understanding effective stress is crucial for predicting soil behavior and ensuring accurate engineering designs. ↩

-

Exploring pneumatics can enhance your knowledge of soil testing methods and improve accuracy in engineering applications. ↩

-

This resource will provide insights into the control mechanisms of constant-p′ and constant-q, crucial for optimizing pneumatic operations. ↩

-

Understanding B-value is crucial for accurate pore measurement, ensuring effective analysis in various applications. ↩

-

Explore how pneumatic controllers enhance efficiency, quality, and safety in testing environments. ↩

-

Learn about the advantages of digital controllers in streamlining data collection and analysis. ↩