Latex membranes look simple, but small choices—material, sizing, storage, and prep—decide whether your test data is clean or noisy.

1) Material & Properties: What Are These Membranes, Really?

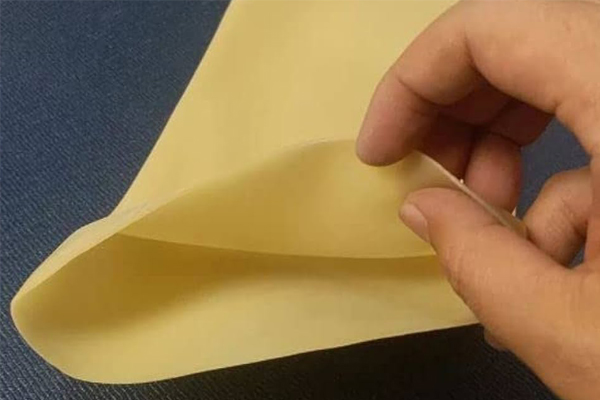

Latex triaxial/permeability membranes are made from high-grade natural latex1 and typically appear a pale milky yellow. The polymer’s elasticity gives them:

- High elongation2 and tear resistance for mounting and shearing

- Good recovery3 to maintain a tight seal under confining pressure

- Close contact with soil, limiting side-wall flow paths

Visual cue: fresh, thin membranes usually look light, creamy yellow; thicker walls can appear slightly deeper in tone.

2) Why Production Is Hard—And Defect Rates Can Be Higher

This is not a mass commodity. Specifications vary widely (diameters, lengths, wall thicknesses), and most steps are manual:

- Small-batch, hand-dipped manufacturing with many touch points

- Large or very thin sizes demand skilled handling; any tiny misstep shows up as wrinkles, thin spots, or pinholes

- Precision limits: without a fully automated line, human factors raise variability, so breakage/defect rates trend higher than consumer goods

Bottom line: a good supplier minimizes variation, but some spread is inherent to craft production.

3) Why the Membrane I.D. Should Be Smaller Than the Sample

A slightly smaller inner diameter4 (≈ 1–3% undersize) is intentional:

- Taut fit under confining pressure prevents folds/wrinkles that distort stress transmission

- Reduces side-wall bypass in permeability: if the sleeve is loose, water can shortcut between soil and membrane, biasing k and flow calculations

- Improves data quality in UU/CU/CD triaxial and flexible-wall permeability

Latex elasticity does the rest—stretching to a smooth, wrinkle-free contact.

4) Storage: How to Maximize Shelf Life

Think dry, sealed, cool, dark:

- Dry: low humidity; include desiccant if possible

- Sealed: airtight bags slow oxidation and ozone exposure

- Cool: avoid heat sources; room temperature or below

- Dark: protect from UV/light that ages latex

These basics preserve elasticity and slow color-shift aging.

5) Best On-Bench Condition: Pre-Use Conditioning for New Membranes

Fresh membranes from factory are light milky yellow and (especially thin walls) can show higher water uptake at first use. For lower water absorption and steadier handling:

- Oven pre-condition at 60 °C for ~1 hour (uniform heating)

- Expect a slightly deeper yellow afterward—this is normal

- Adjust time by trial for your wall thickness and lab conditions

Aim: make the sleeve a touch drier and dimensionally calm before contact with the specimen—often improving installation feel and early-stage behavior.

6) Reading Service Life by Color

Color is a handy proxy:

- Fresh / newer: pale, milky yellow

- Aged / near end-of-life: deeper yellow trending to reddish hues

- At this stage, elasticity and tear resistance may drop; treat as short-life stock or retire

Always pair color checks with a quick low-pressure hold test5 to confirm seal integrity.

7) Wall-Thickness Variation: Why It Exists (and Why Thick Sleeves “Feel” Uniform)

Dipped membranes are formed by immersing a mandrel in liquid latex. One end inevitably enters earlier and dwells longer, depositing more latex:

- Process reality: one-end-first immersion → axial thickness gradient

- Manual touch can add small variation between pieces

Perception differs by thickness:

- Thin sleeves (e.g., 0.3 mm): a 0.1 mm change is noticeable by hand and can influence small-strain stiffness

- Thick sleeves (1–3 mm): the same 0.1 mm shift is proportionally smaller—often not discernible by feel

Practical tip: for thin sleeves in precision work, map thickness at a few points or choose a vendor with documented thickness profiles6.

Quick Reference: Field-Proven Practices

- Sizing: target 1–3% undersize I.D. vs sample diameter

- Storage: dry + sealed + cool + dark

- Pre-use: 60 °C × 1 h oven conditioning for thin/light sleeves

- QC on arrival: do a 10–20 kPa, 2–5 min hold; Δp ≈ 0 indicates healthy seals

- Replace stock showing dark yellow → reddish tones, whitening, cracking, or sticky feel

Conclusion

Latex membranes are small parts with big impact. Choose a slightly undersized, well-stored sleeve; pre-condition smartly; watch color as a life indicator; and respect the realities of hand-dipped production. Your triaxial and permeability results will be cleaner—and your retest rate lower.

-

Explore the unique properties of high-grade natural latex to understand its benefits in soil mechanics. ↩

-

Learn about high elongation and its significance in material performance, especially in soil testing. ↩

-

Discover how good recovery affects the performance of materials under pressure, crucial for accurate testing. ↩

-

Understand the importance of inner diameter in ensuring accurate test results in soil mechanics. ↩

-

Explore the low-pressure hold test and its role in ensuring the integrity of latex membrane seals. ↩

-

Discover the significance of thickness profiles in selecting high-quality latex membranes for testing. ↩