Custom Triaxial Sample Compactors: Designed for Professional Geotechnical Labs

Standard gear is fine—until you ask it for tighter tolerances, cleaner logs, and calmer specimens across mixed soils. That’s where custom compactors earn their keep.

Why Standard Compactors Fall Short in Professional Labs

Off-the-shelf units are built for “typical” soils, “average” throughput, and minimal data. Professional labs rarely live there.

Common gaps

- Control limits: fixed blow counts or crude pressure knobs can’t hold ±2% pressure1 or ±0.2 s dwell—the difference between neat overlays and noisy curves.

- Geometry inflexibility: one or two diameters, awkward height spacers, and no quick-change mold clamps slow multi-size programs.

- Data silence: counters without timestamps2, setpoint/actual logs, or API lock your process out of LIMS/DAQ.

- Soil diversity: clean sands need vibration options; sensitive clays need static–cyclic with gentle rates; standards don’t do both well.

- Ergonomics & safety: real throughput needs hands-free clamping, guarded starts, and fixtures that prevent tilted end faces.

Symptoms you’ll recognize

- Specimens pass eyeball checks but scatter under shear.

- Techs improvise “workarounds” the SOP never envisioned.

- You can’t prove what happened between lift 2 and lift 3—because nothing was recorded.

Key Customization Options for Triaxial Compactors

Customization isn’t about bells and whistles—it’s about removing the variables that make specimens disagree.

1) Compaction Method & Control

- Static–cyclic press with programmable pressure ramps3, rate limits, and dwell; accuracy ≤ ±2%.

- Drop-hammer modules with verified drop height4 (≤ ±1 mm) and auto-rotate passes.

- Vibration assist (amplitude/frequency control) for granular soils with anti-segregation plates.

- End seating step (low-pressure flatten) to deliver parallel faces every time.

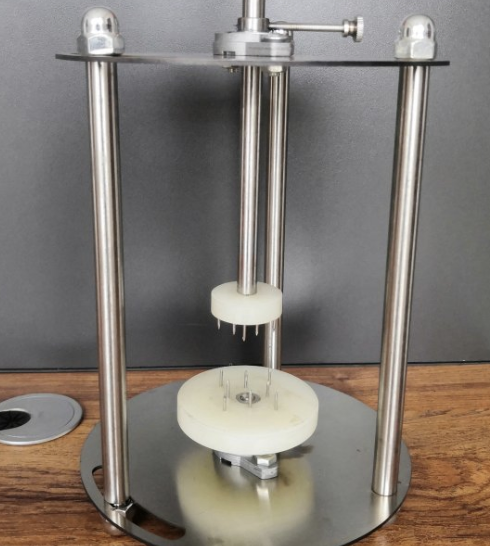

2) Geometry & Tooling

- Quick-change diameter kits (e.g., Ø35/38/50/70 mm) and height spacers for H/D 2.0 ± 0.1.

- Self-centering, hands-free mold clamps; membrane collars compatible with sleeve roll-down.

- Strike-off and trimming fixtures matched to your caps and membranes.

3) Sensing & Feedback

- Integrated load/pressure sensors (traceable calibration), lift timers, and blow counters.

- Optional displacement capture for lift thickness verification.

- Health sensors (cycle count, temp) to schedule maintenance before drift appears.

4) Data, Software, and Security

- HMI with SOP lock, user roles, barcode/QR specimen IDs.

- CSV/JSON export + REST/RS-485 API for LIMS/DAQ; time-stamped setpoint vs actual per lift.

- On-board checklists (moisture, mass, geometry) and automatic accept/reject flags.

5) Ergonomics & Safety

- Two-hand/guarded cycle start, light curtains (if required), E-stop.

- Foot-pedal clamping, counterbalanced heads, and clear sightlines for high throughput.

Quick option matrix

| Axis | Option | When to choose |

|---|---|---|

| Method | Static–cyclic press | Sensitive clays/silts; uniform density |

| Drop-hammer | Granular soils; rugged QA | |

| Vibration add-on | Clean sands; densification without over-blows | |

| Data | HMI + CSV | Basic traceability |

| API + user roles | LIMS/DAQ integration, multi-operator labs | |

| Tooling | Quick-change molds | Frequent size changes |

| Safety | Guarded start + E-stop | High-cycle labs, compliance needs |

Benefits of Custom-Built Systems in Research and QA Labs

Why pro labs go custom: fewer retests, tighter overlays, and audit-ready proof of what happened to every specimen.

- Measurement quality: uniform lifts → narrower COV5 for ρ_d and moisture → calmer CU/CD curves.

- Repeatability: programmable cycles remove “operator rhythm” from density and fabric.

- Throughput: quick-change molds and SOP-driven screens increase specimens/day without sacrificing quality.

- Traceability: time-stamped lift logs (setpoint/actual) end arguments in design reviews.

- Versatility: run sands in the morning (vibration/hammers), clays in the afternoon (static–cyclic), without swapping machines.

- Cost of quality: fewer do-overs and faster sign-off often outpace the price delta within a few projects.

Before/after snapshot

| Metric | Standard Unit | Custom System |

|---|---|---|

| Pressure/dwell control | Manual/approximate | Closed-loop, programmable |

| Size changeover | 10–20 min | < 3–5 min |

| ρ_d scatter (program) | Higher COV | Lower COV (uniform lifts) |

| Data trail | Counters only | Full lift-by-lift log + API |

| Retest rate | Frequent | Rare (root causes visible) |

Collaborating with Manufacturers for Tailored Solutions

Custom works when you bring real constraints and accept tests to the table.

1) Define the problem, not the part

- Soils you actually run (PSD, plasticity), target ρ_d / w%, required H/D, daily throughput6.

- Accuracy needs (e.g., ±2% pressure, ±0.2 s dwell) and the standards you follow.

2) Co-design the control philosophy

- Choose method (static–cyclic vs hammer/vibration) and set tuning ranges (rate, ramp, dwell).

- Specify what must be recorded: lift masses, timers, pressure traces, operator IDs.

3) Nail data and IT early

- File format (CSV/JSON), field names, timestamp source, and API endpoints7.

- User roles, SOP lock, calibration reminders, and audit export (PDF/CSV).

4) Prove it with acceptance tests (FAT/SAT)

- Energy/pressure repeatability: 10 cycles on a dummy load; COV ≤ 3%.

- Lift uniformity: build a specimen; lift thickness ±5%.

- End seating: straightedge gap < 0.05 mm after seating step.

- Throughput: timed run for your most common mold.

- Data export: import to LIMS/DAQ; verify headers and timestamps.

5) Plan maintenance and training

- Field-replaceable wear items (bushings, plates, sensors) with spares list.

- Operator training + a one-page bench card embedded on the HMI.

Sample collaboration checklist

- [ ] Soils & targets documented (ρ_d, w%, sizes)

- [ ] Method & control specs agreed

- [ ] Data schema & API mapped

- [ ] FAT/SAT scripts approved

- [ ] Spares & maintenance plan in PO

- [ ] Training + SOP lock-in scheduled

Conclusion

Custom triaxial compactors pay for themselves in uniformity, speed, and proof. Specify the control you need, the sizes you actually run, and the data you must defend—then co-develop with a manufacturer who will test it with you, not just ship it to you. When the compactor gets boringly consistent, your soil plots finally get interesting for the right reasons.

-

Understanding ±2% pressure is crucial for ensuring accuracy in lab tests, which can significantly impact results. ↩

-

Exploring the importance of timestamps can enhance your understanding of data integrity and process tracking in lab environments. ↩

-

Understanding pressure ramps can enhance your knowledge of precision in static-cyclic presses. ↩

-

Exploring drop height verification methods can improve your insights into drop-hammer module accuracy. ↩

-

Understanding narrower COV can enhance your knowledge of measurement quality and its impact on lab results. ↩

-

Calculating daily throughput helps optimize operations and improve efficiency in your processes. ↩

-

Understanding API endpoints is crucial for effective data management and integration in your projects. ↩