How Butyl Rubber is Changing the Game in Modern Waterproofing Solutions

From basements and rooftops to lab-grade seals and tunnels, butyl rubber is fast becoming the go-to solution in waterproofing. Why? Because it offers a rare balance of reliability, flexibility, and impermeability. In a world where leaks mean damage, downtime, or data loss, butyl rubber is helping professionals build with more confidence and less maintenance.

Self-Sealing Advantage: No More Leaks or Failures

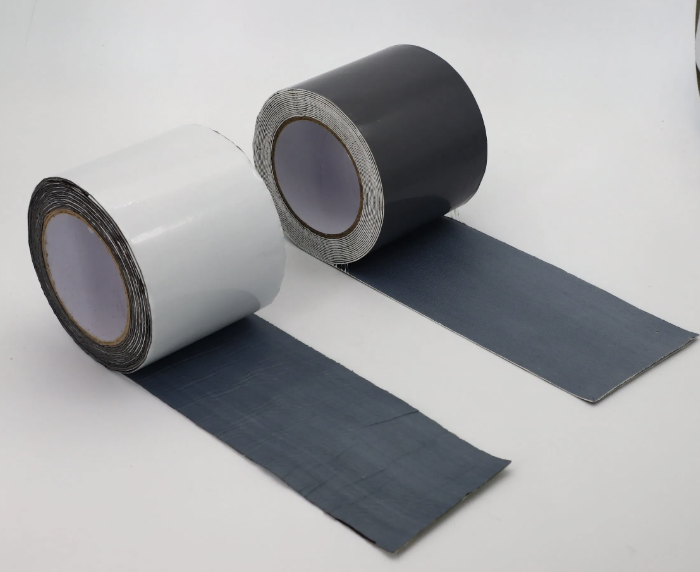

One of butyl rubber’s standout features is its self-sealing capability. Unlike traditional membranes that rely on tapes, glues, or heat welding, butyl forms a tight bond on its own—especially when applied as a pre-formed sheet or tape.

Why This Matters:

- Microcracks or punctures? Butyl flows slightly to reseal itself.

- Around bolts or irregular joints? It wraps and clings naturally.

- Installation errors? The material forgives minor misalignments.

| Feature | Impact |

|---|---|

| Self-sealing ability1 | Reduces leak risk without extra labor |

| Cold-applied application2 | No need for heat tools |

| Seamless integration3 | Great for complex shapes and transitions |

Whether you’re sealing a window flashing or running a triaxial soil test, butyl rubber delivers peace of mind—no glue, no gaps, no surprises.

Built to Last: Withstanding Time, Sun, and Stress

Waterproofing isn’t just about stopping leaks today—it’s about holding strong for decades. Butyl rubber stands out for its durability under tough environmental conditions.

Built-In Durability:

- UV and ozone resistant4: Won’t crack or chalk under sun exposure

- Thermal stability5: Performs from -40°C to +120°C

- Aging resistance6: Maintains elasticity for 20+ years

| Environmental Stress | Butyl Rubber Performance |

|---|---|

| UV exposure | Excellent resistance |

| Freeze-thaw cycles | Remains flexible and sealed |

| Salt spray / humidity | Chemically stable |

| Vibration / mechanical flex | Stretches without delaminating |

In roofing, underground sealing, and tunnel lining, butyl rubber proves again and again that it’s built for the long haul.

Tight Seals, Clean Results: Chemical and Vapor Barriers

For projects that deal with soil gases, chemicals, or high humidity, ordinary membranes fall short. Butyl rubber steps in with exceptionally low permeability.

Why It Works:

- Dense molecular structure7 blocks air, water vapor, and VOCs

- Acts as a permanent chemical barrier8 in lab, industrial, and agricultural environments

- Ideal for permeability-sensitive applications9 like triaxial testing and green building

| Barrier Type | Butyl Rubber Effectiveness |

|---|---|

| Water | 100% waterproof |

| Vapor | Near-zero vapor transmission |

| Soil gases (e.g., radon) | Excellent resistance |

| Chemical exposure | Non-reactive to many solvents |

From environmental containment to lab equipment sealing, butyl makes your waterproofing smart, not just strong.

Flexibility Meets Function: Easy Application Across All Surfaces

While some membranes demand flat, clean surfaces and perfect prep, butyl adapts to real-world complexity. Uneven concrete? Corrugated metal? Butyl sticks—and stays stuck.

What Installers Love:

- Self-adhesive: No torch, no liquid glue, no curing time

- Form-fitting: Wraps around pipes, joints, bolts, and corners

- Time-saving: Fewer steps, fewer callbacks

| Application Scenario | Butyl’s Advantage |

|---|---|

| Vertical or overhead work | High tack holds position instantly |

| Rough masonry | Conforms and seals without primer |

| Lab environments | Compatible with metal, plastic, and glass |

Whether you’re sealing a leaky window frame or building a below-grade waterproof barrier, butyl works with you—not against you.

Conclusion

In a market flooded with generic sealing solutions, butyl rubber stands out by offering what others can’t: a self-sealing, long-lasting, vapor-tight, and easy-to-apply membrane. It’s changing how architects, engineers, and researchers think about waterproofing—from a one-time fix to a long-term solution.

-

Explore how self-sealing materials can enhance your projects by reducing leak risks and labor costs. ↩

-

Learn about cold-applied applications and how they simplify installation without the need for heat tools. ↩

-

Discover the advantages of seamless integration in construction for complex shapes and transitions. ↩

-

Explore this link to understand how UV and ozone resistant materials can enhance durability and longevity in various applications. ↩

-

Learn about thermal stability and its critical role in ensuring materials perform well under extreme temperatures. ↩

-

Discover the significance of aging resistance in materials, ensuring they maintain performance over time, especially in harsh conditions. ↩

-

Understanding dense molecular structures can enhance your knowledge of material science and its applications in various industries. ↩

-

Exploring permanent chemical barriers can provide insights into their importance in safety and environmental protection across different sectors. ↩

-

Learning about permeability-sensitive applications can help you grasp their critical role in engineering and environmental sustainability. ↩