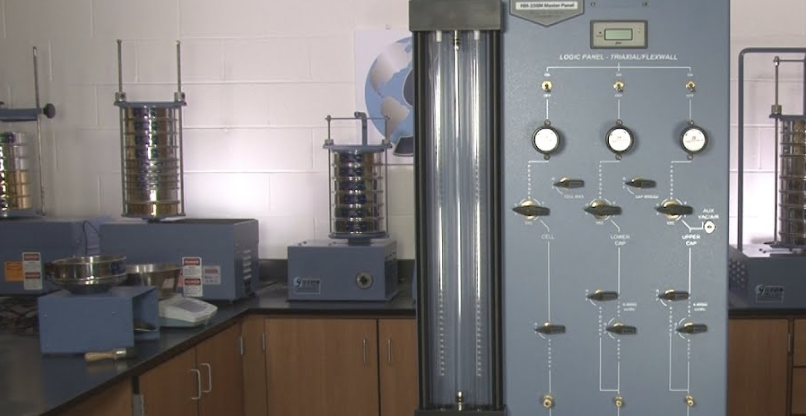

Pneumatic Pressure Controllers in Triaxial Tests: Precision Control for Soil Mechanics

When pressures are steady, soil stories get clear. Pneumatic controllers keep cell and back pressure honest, so my triaxial results stop wobbling and start matching reality.

Pneumatic pressure controllers deliver fast, low-overshoot ramps and stable holds for cell/back pressure. That precision keeps effective stress true, speeds saturation, cleans B-checks, and tightens CU/CD stress-path repeatability.

Let’s unpack why precision matters, how stress paths improve, and where pneumatics strengthen saturation, B-checks, and lab automation.

Why Is Precision Control Critical in Soil Mechanics?

Good soil mechanics is quiet mechanics. If pressure wanders, effective stress1 lies—and design values drift.

Stable cell and back pressure prevent fake stiffness, pore-pressure drift2, and noisy volume change, revealing the soil’s real stiffness, strength, and permeability.

Making effective stress honest

I still remember a “strong” clay that wasn’t. The regulator overshot, dipped, then settled; those tiny swings inflated stiffness and muddied Δu. We switched to a pneumatic controller with closed-loop feedback. The ramp hit setpoint without drama. The stress path relaxed into the shape I expected, and the modulus finally made sense.

- Effective stress is sensitive. A small pressure wobble shifts ( \sigma’ = \sigma – u ). Keep both σ₃ and back pressure steady to protect p′ and q. See my effective-stress primer here.

- Holds expose leaks. A flat, quiet hold tells you seals and stones are healthy. Run a 10–20 kPa hold, watch ΔV. Try the hold-test script here.

- Noise has a map. Overshoot, thermal creep, micro-leaks—each has a pattern. My noise checklist lives here.

Manual vs pneumatic—why it shows up in plots

| Item | Manual/weights | Pneumatic controller |

|---|---|---|

| Ramp behavior3 | Overshoot/undershoot | Low-overshoot, rate-limited |

| Hold stability4 | Draft-sensitive | Active feedback, steady |

| Setpoint step | Coarse | Sub-kPa (device-dependent) |

| Data trace | Noisy, laggy | Smooth, reproducible |

A small rule I keep: if plots look anxious, stabilize pressure first. You can’t compute truth from shaky inputs.

How Do Pneumatic Controllers Improve Stress Path Testing?

Stress paths are choreography: the axial system pushes q, while cell/back pressure shape p′. Timing is everything.

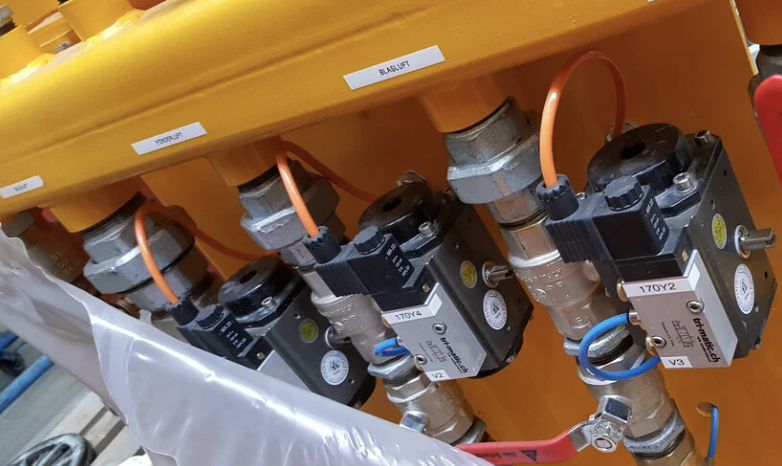

Closed-loop pneumatics synchronize channels for constant-p′5, K₀, and custom paths6—less lag, fewer corrections, tighter overlays across specimens.

Choreography without drama

With constant p′, I increase σ₃ while adjusting back pressure so ( p′ = (\sigma_1′ + 2\sigma_3′)/3 ) stays fixed as q changes. For K₀ consolidation, the controller nudges confinement to track the lateral stress ratio without bouncing. In true triaxial/advanced cells, multi-channel sync avoids phase errors that quietly pollute the path.

- Path planner. Script segments, rates, and limits before you touch a sample. My planner is here.

- Rate guards. Cap slew rates for soft clays; protect fabric while moving the path. Notes here.

- Leak precheck. A 90-second sanity test prevents an hour of bad data. Guide here.

Patterns I run a lot

| Pattern | Pneumatic move | Why it helps |

|---|---|---|

| Constant-p′ shear | σ₃↑ while u_b adjusts | Holds mean stress while q rises |

| K₀ loading | σ₃ steps follow target K₀ | Clean lateral stress development |

| Partial drainage | Tiny head control | Honest volumetrics and k |

| Cyclic biasing | Soft-edge waveforms | No pore-pressure shocks |

If the setpoint vs achieved logs don’t match, fix actuation before blaming the soil. My audit overlay template is here.

What Role Do They Play in B-Value and Saturation Checks?

B-checks should be boring; saturation should be calm. Pneumatics make both predictable.

Controllers apply small, repeatable pulses for ( B = \Delta u / \Delta \sigma_3 ) and hold gentle back-pressure steps—so B rises smoothly and stays stable.

From bubbles to believable B

I run CO₂ → de-aired water, then step back pressure while trimming cell pressure to keep ( \sigma′ \approx 2–5 ) kPa. Between steps, I pause; if volume drift is near zero, I move on. For B-checks, a crisp +20 kPa cell pulse gives a clean Δu. Two pulses, same B? Green light. If B drifts, I hunt stones, lines, or a cranky O-ring—not the actuator.

- Saturation ladder. 25–100 kPa steps (soil-dependent), patient holds. Card here.

- Pulse hygiene. Small, fast, repeatable. Pulse card here.

- Stone care. Re-boil, back-flush, retire on schedule. Guide here.

B-value bands (and what I do)

| B-range | Meaning | Action |

|---|---|---|

| ≥ 0.98 | Excellent | Proceed to consolidation/shear |

| 0.95–0.98 | Good | Proceed; log and watch drift |

| 0.90–0.95 | Borderline | Extend holds; clean lines/stones |

| < 0.90 | Not ready | Re-saturate; leak hunt |

Anecdote: we chased scatter for days. The villain? A “fine” porous stone. After a back-flush and swap, B locked at 0.98 and CU paths lined up like rails.

Why Are They Essential for Modern Automated Geotechnical Labs?

Modern labs live on speed, traceability, and safety. Pneumatics help with all three—quietly.

They automate profiles, reduce re-tests, generate full audit trails7, and integrate with DAQ—raising throughput and confidence for CU/CD, permeability8, and cyclic programs.

Throughput without shortcuts

Scripted ramps and holds let technicians run more specimens with fewer interruptions. Every setpoint and achieved value is logged, so defending results months later is painless. No oil columns, no heavy weights, less mess. And training becomes simpler: new techs follow the same calm profile and get the same calm data.

- Profile library. CU, CD, constant-p′, cyclic—ready to run. Library here.

- QA bands. Pass/fail thresholds for ramps and holds. Bands here.

- Data stitcher. Merge controller logs with DAQ time stamps. Tool here.

- Weekly ritual. Quick cal + leak test before programs. Checklist here.

Snapshot: why labs switch

| Benefit | What improves |

|---|---|

| Fewer re-tests | Stable ramps/holds remove borderline runs |

| Cleaner audits | Automatic, timestamped logs |

| Safer workflows | No oil handling or weights |

| Better decisions | Tighter parameters → clearer designs |

When plots finally look relaxed—no jitters, no spikes—you feel it in the room. Quiet pressure. Honest soil. Better choices.

Conclusion

Make pressure precise and calm; your saturation, B-checks, and stress paths will finally tell the truth.

-

Understanding effective stress is crucial for accurate soil behavior predictions and engineering designs. ↩

-

Exploring pore-pressure drift helps in grasping its impact on soil stability and construction projects. ↩

-

Understanding ramp behavior is crucial for optimizing control systems and ensuring stability. ↩

-

Exploring hold stability can enhance your knowledge of maintaining consistent performance in various applications. ↩

-

Understanding constant-p′ can enhance your knowledge of efficient pneumatic systems and their applications. ↩

-

Exploring custom paths will reveal innovative techniques that optimize pneumatic system performance. ↩

-

Understanding audit trails can enhance your lab's efficiency and compliance, ensuring better data integrity. ↩

-

Exploring permeability testing can provide insights into material properties, crucial for various lab applications. ↩