What I Wish I Knew Before Running My First Triaxial Test

My first triaxial test looked perfect—until the curves started arguing with each other. Years later, here’s the short list I wish someone had taped to the load frame: B-value first, boundaries matter, rate is a decision, and seals make or break trust.

“B-Value First: The Real Gatekeeper of Data Quality”

If the specimen isn’t saturated, everything downstream—effective stresses, c–φ, stiffness—becomes a polite fiction.

Clean, fast saturation sequence1 (CU/CD):

- CO₂ flush porous stones and lines → de-aired water fill.

- Step back pressure in 25–100 kPa increments while holding σ′ ≈ 2–5 kPa (adjust cell pressure).

- Pause each step until volume drift ~ 0.

- Run two crisp B-checks (+Δσ₃ ≈ 20 kPa); values should agree within a few thousandths.

| B-value | Meaning | Action |

|---|---|---|

| ≥ 0.98 | Fully saturated | Proceed |

| 0.95–0.98 | Acceptable with note | Proceed, watch Δu |

| 0.90–0.95 | Air/leak somewhere | Extend holds; back-flush stones; new O-rings |

| < 0.90 | Not saturated | Stop, fix, restart |

Pro tips

- Old porous stones and tired O-rings are cheap villains; replace early.

- A slow last 50–100 kPa of back pressure often moves B from 0.95 to 0.99.

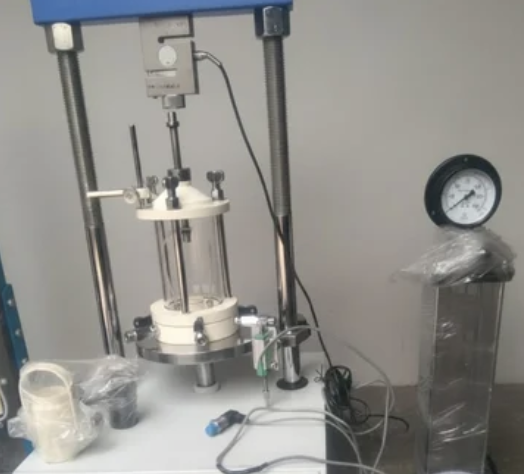

“It’s Not Just the Machine—It’s the Boundary Conditions”

A perfect controller can’t fix bad boundaries. End friction, sleeve stiffness, and plumbing decide whether your stress path is honest.

Good boundary conditions3 look like:

- Ends: flat/parallel (straightedge gap < 0.05 mm); seating pressure step applied.

- Membrane: 1–3% undersized I.D., no folds; cap edges deburred/polished.

- Stones & drains: clean, back-flushed; lines de-aired; valve map labeled.

- Hold integrity: 10–20 kPa cell pressure, 2–5 min hold → Δp ≈ 0 before you start.

Symptom → Boundary cause → Fix

| Symptom | Likely Boundary Issue | Practical Fix |

|---|---|---|

| Early “too-stiff” curve | Thick/loose membrane4; end tilt | Thinner/snug sleeve; re-trim ends; seating step |

| Wavy CD volumetrics | Drain restriction / trapped air | Back-flush lines; increase vent area; slower rate |

| Δu spikes in CU | Controller overshoot or micro-leak | Add ramp limits; replace O-rings; tighten fittings |

| Side-wall bypass in k-tests | Loose sleeve / folds | Undersize membrane; smoother surface; re-fit |

“Shear Rate Controls Drainage: Set It with Intent”

Rate isn’t a guess—it’s how you enforce the drainage condition you claim.

Pick rate by behavior, not habit

- CU (undrained): fast enough that volume ≈ constant and Δu responds smoothly.

- CD (drained): slow enough that Δu ≈ 0 and volumetric strain is smooth (no stair-steps).

How I set it (works reliably):

- During consolidation, estimate t₉₀ (time to 90% consolidation).

- Start with an axial strain rate5 such that a small strain increment (e.g., 0.5–1% in CU; 0.2–0.5% in CD) takes ≳ 10–20% of t₉₀6 for CD and ≲ 5% of t₉₀ for CU.

- Watch Δu (CU) or Δu ~ 0 & smooth v-change (CD) for the first 1–2% strain. Adjust once, then hold.

Controller hygiene

- Enable ramp limits on cell/back-pressure steps; tune PID to avoid overshoot.

- Log setpoint vs achieved—overlays should be tight. If not, your “rate” isn’t what you think it is.

“Seal, Saturate, and Then Trust Your Curves”

Trust comes from a clean start and consistent math.

Before you believe a curve

- Leak pre-check passed (Δp ≈ 0).

- B-value7 documented (≥ 0.95–0.98).

- Area correction applied (use (A \approx A_0/(1-\varepsilon_a)) or (A_0(1-\varepsilon_v)/(1-\varepsilon_a)) if ε_v is measured).

- Failure criterion chosen once (peak q or fixed strain, e.g., 15%) and used for all tests.

From numbers to parameters (p′–q is your friend)

- At failure, compute effective stresses8: (\sigma'_1 = \sigma_1 – u_f), (\sigma'_3 = \sigma_3 – u_f).

- (q = \sigma'_1 – \sigma'_3), (p' = (\sigma'_1 + \sigma'_3)/2).

- Regress (q = M p' + k); then

[

\sin\varphi'=\frac{3M}{6+M},\quad

c'=\frac{k(3-\sin\varphi')}{6\cos\varphi'}

] - Report c′, φ′ with the failure rule, corrections, and any excluded points (and why).

Five quick sanity checks

- Duplicate a specimen (or condition); overlays should match within your acceptance band.

- CU: Δu monotonic; no spikes.

- CD: Δu ~ 0; volumetrics smooth.

- Setpoint ≍ achieved for pressures.

- Outlier? Re-inspect B, leaks, area correction, rate—don’t just “average harder.”

Pocket Bench Card (print this next to your frame)

- Specimen: ρ_d/e₀ on target (±1–2%), lifts ±5%, ends flat, membrane undersized 1–3%, leak hold OK.

- Saturation: stepped BP with σ′ ≈ 2–5 kPa; B ≥ 0.95–0.98 (twice).

- Rate: CU fast enough for undrained; CD slow enough for Δu ~ 0; adjust once, then lock.

- Control: ramp limits on; setpoint vs achieved tight.

- Analysis: area correction, consistent failure rule, p′–q fit → c′, φ′. Archive raw + processed + calibration.

Final Thought

Triaxial success isn’t magic—it's habits. Chase B-value, respect boundaries, choose rate with purpose, and protect the seal. Do those four, and your plots get quiet, your parameters get trustworthy, and your retests get rare.

-

Understanding the saturation sequence is crucial for accurate soil testing and analysis, ensuring reliable results. ↩

-

Exploring B-value triage helps in diagnosing saturation issues, leading to better soil stability and project success. ↩

-

Understanding boundary conditions is crucial for ensuring accurate results in engineering applications. Explore this link for detailed insights. ↩

-

Membranes play a vital role in various engineering systems. Discover their importance and applications by following this link. ↩

-

Understanding strain rate is crucial for accurate modeling in geotechnical engineering, ensuring reliable results in soil behavior. ↩

-

Exploring t₉₀ calculations can enhance your knowledge of soil consolidation processes, leading to better engineering practices. ↩

-

Understanding B-value is crucial for accurate soil behavior predictions and ensuring reliable engineering designs. ↩

-

Calculating effective stresses is fundamental for analyzing soil stability and strength, making this resource invaluable for engineers. ↩