What Is a Ring Cutter in Soil Triaxial Testing? A Complete Guide

A ring cutter (cutting ring) is a thin-walled, sharpened cylinder used to carve and size a soil specimen to the exact diameter for triaxial testing—typically 38, 50, or 70 mm. It helps achieve tight dimensional tolerances with minimal disturbance so your stress–strain curves and B-values are trustworthy.

How Does a Ring Cutter Work in Triaxial Testing?

The ring cutter trims and lifts a cylindrical plug from a larger undisturbed or reconstituted sample. In triaxial prep it serves two roles: cutting to diameter1 and holding the specimen while you true the ends.

Typical workflow

-

Seat & align

Place the block/tube sample on a trimming stand. Center the ring cutter over the target location. -

Cut

Press and gently rotate the ring (small oscillations) so the beveled edge slices in. Avoid aggressive twisting which smears clays. -

Extract

Once full penetration is reached, use an ejector plunger or base plate to push the specimen out onto the pedestal. -

True the ends

Flush-trim top/bottom using a wire saw or piano wire and a straightedge jig to achieve parallel ends and target height (H ≈ 2D per common triaxial practice). -

Install

Place porous stones and top cap, fit the latex membrane2 (membrane stretcher recommended), add O-rings, and proceed to saturation.

Why this works: a thin, sharp wall reduces side friction and fabric disturbance, preserving structure in soft clays and silts.

Why Use a Ring Cutter Instead of Other Sampling Tools?

| Tool / Method | Best At | Limitations | When I pick it |

|---|---|---|---|

| Ring cutter3 | Quick, low-disturbance diameter trim | Not ideal for very coarse soils | Routine CU/CD on clays/silts |

| Split mold + hand trim | Flexible shapes/sizes | Operator-dependent; slower | Special diameters, teaching |

| Soil lathe / sanding jig | Very parallel ends & fine tolerances | Time-consuming; needs fixtures | Research where end parallelism dominates |

| Core barrel (thin-wall)4 | Field extraction of undisturbed cores | Separate lab trimming still needed | Site to lab workflow |

Advantages of ring cutters

- Consistency: Fast, repeatable diameters within ±0.1 mm (or better with good tooling).

- Lower disturbance: Thin, sharp edge minimizes smearing in soft fine-grained soils.

- Throughput: Ideal for multi-specimen programs where prep time matters.

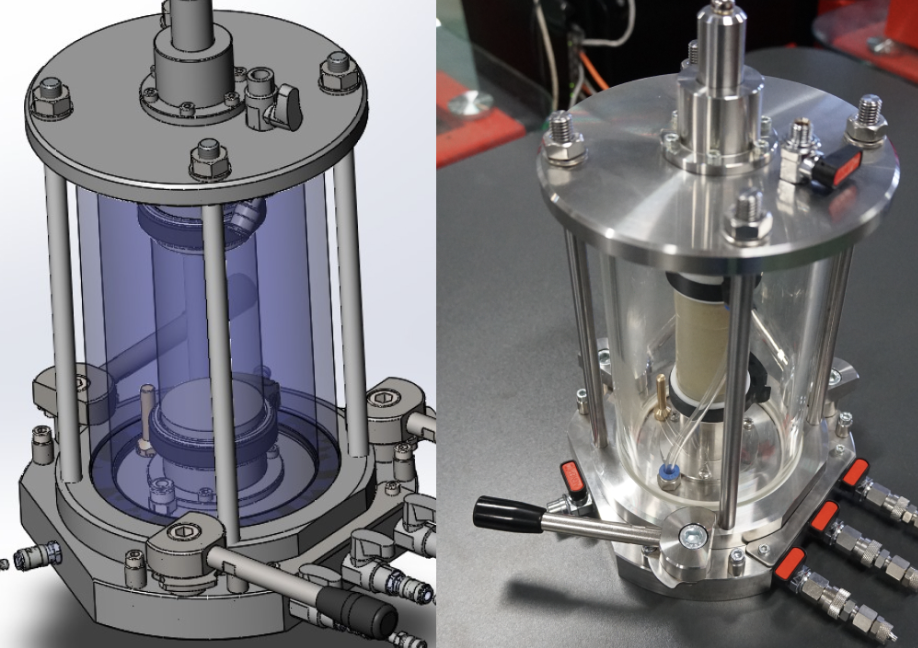

What Are the Key Features of a Good Ring Cutter?

-

Material & finish

- Stainless 304/3165 for corrosion resistance.

- Mirror-polished bore (low friction) and rounded outer rim (safe handling).

-

Cutting edge geometry

- Single-bevel6 20–30° leading edge; thin wall (often ≤2 mm for 38–50 mm rings).

- Uniform bevel with no nicks—micro-chipping tears membranes and smears clays.

-

Dimensional accuracy

- Inside diameter matched to your triaxial system (e.g., 38.00 ±0.02 mm).

- Cylindricity and roundness within tight tolerance for uniform stress state.

-

Handling features

- Knurled grip or flange for safe pressing/rotation.

- Ejector plunger matched to the ID with a low-friction face.

- Alignment collar or guide ring to keep cuts vertical.

-

Serviceability

- Edge can be re-honed; spare plungers available.

- Laser-etched size/ID for quick identification.

Pro tip: Keep a “metrology ring” (gold-standard cutter) you don’t loan out; use it to gauge whether production rings have dulled.

Best Practices for Using Ring Cutters in Soil Triaxial Testing

Preparation

- Condition the sample: Keep clays at in-situ water content; seal against drying (wrap + lid) until the moment of trimming.

- Stabilize the block: Use a non-slip base and a vertical guide to prevent tilt.

- Check sharpness: A dull ring raises side friction and fabric disturbance—re-hone as needed.

Cutting technique

- Press, don’t screw: Apply steady axial pressure7 with small oscillations (±10–20°). Avoid full rotations that smear.

- Control rate: Advance ~1–2 mm per oscillation on soft clays; slower for sensitive soils.

- Mind coarse grains: If sand or gravel resists entry, don’t force it—switch to a larger diameter or alternative prep.

Extraction & end-trimming

- Use the plunger: Push the specimen out evenly; do not pull from the top (risk of tension cracks).

- True the ends: Wire-saw flush to a height ≈ 2× diameter (e.g., 76 mm for D=38 mm). Check parallelism with a machinist’s square or gauge.

Membrane & assembly

- Wet the surface lightly with de-aired water8; avoid oils.

- Install via membrane stretcher; use double O-rings on each end.

- Bottom-up flooding during initial fill to push air upward.

QA checks (quick)

- Measure D and H with calipers (three diameters, average).

- Inspect for smear zones on the side; if present, consider re-trimming lightly.

- Log dimensions for area corrections and density/void ratio calculations.

Safety & care

- Use cut-resistant gloves; store rings in a padded sleeve.

- Rinse with de-aired water, dry fully, and cap edges to avoid knocks.

- Keep a maintenance log (sharpens, nicks, drops).

Sizing Reference (common triaxial specimens)

| Nominal Diameter (mm) | Target Height (mm) | Typical Ring Wall (mm) | Typical Use |

|---|---|---|---|

| 38 | 76 | 1.0–1.5 | Routine CU/CD on clays/silts |

| 50 | 100 | 1.2–2.0 | Mixed soils; research rigs |

| 70 | 140 | 1.5–2.5 | Heterogeneous or coarser mixes |

Aim for H/D ≈ 2 unless your standard specifies otherwise.

Conclusion

A well-designed ring cutter, used with calm, repeatable technique, is one of the fastest ways to reduce specimen disturbance and prep time in triaxial testing. Focus on sharp, thin walls; precise diameters; smooth bores; and disciplined end-trimming. Pair the result with a membrane stretcher and bottom-up flooding, and you’ll see the payoff—higher B-values, fewer leaks, and cleaner stress–strain curves across your program.

-

Understanding this process is crucial for accurate specimen preparation in triaxial testing, ensuring reliable results. ↩

-

Exploring the function of the latex membrane can enhance your knowledge of specimen integrity and testing accuracy. ↩

-

Explore the benefits of ring cutters for soil sampling, including consistency and lower disturbance, to enhance your research methods. ↩

-

Learn about the core barrel’s role in extracting undisturbed soil cores, crucial for accurate lab analysis and research. ↩

-

Explore this link to understand why Stainless 304/316 is preferred for its corrosion resistance and durability in various applications. ↩

-

Discover how a Single-bevel cutting edge enhances precision and performance in cutting applications. ↩

-

Understanding steady axial pressure is crucial for effective soil sampling techniques, ensuring accurate results. ↩

-

Exploring the role of de-aired water can enhance your knowledge of soil sampling methods and improve sample quality. ↩