What is Butyl Rubber Membrane?

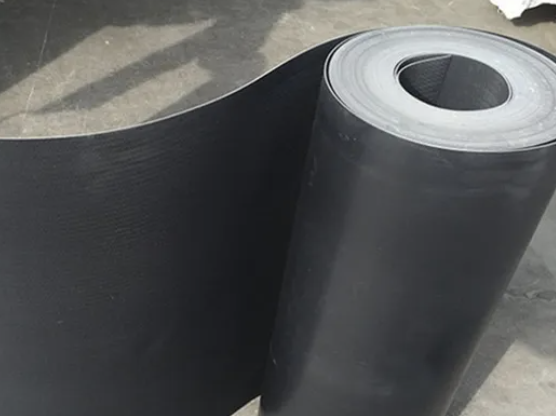

Butyl rubber membrane is a flexible, durable, and highly impermeable sheet material made from isobutylene-isoprene rubber. Known for its superior water and air resistance, it is widely used in construction, roofing, underground waterproofing, and sealing applications where long-lasting protection is critical.

This synthetic membrane stands out for its ability to maintain elasticity across temperatures and resist UV, ozone, and chemical degradation—making it a reliable choice in both civil engineering and industrial contexts.

Key Properties of Butyl Rubber Membrane

Butyl rubber membranes are valued for their unique combination of elasticity, chemical stability, and low gas permeability1.

| Property | Performance |

|---|---|

| Water vapor permeability | Extremely low; ideal for waterproofing |

| Elasticity | High elongation at break (300%–600%) |

| UV and ozone resistance | Excellent, does not crack or degrade easily |

| Temperature tolerance | Performs in -40°C to +100°C environments |

| Chemical resistance | Resistant to acids, alkalis, and polar solvents |

| Durability | Service life of 20–30 years in many applications |

These properties make butyl membranes highly adaptable for both indoor and outdoor sealing needs, especially where moisture and air infiltration2 are primary concerns.

Common Applications in Waterproofing and Sealing

Thanks to its self-adhesive nature3 and excellent sealing capability, butyl rubber membranes are used across a variety of industries.

Typical Use Cases:

- Roofing: As underlays or flashings for waterproofing roof joints4 and valleys

- Basement and foundation waterproofing: Prevents groundwater ingress

- Window and door flashing: Forms an air and water-tight seal around frames

- Pipe and duct sealing: Especially where vibration or movement occurs

- Automotive and HVAC: Used for sound damping and vibration control5

| Industry | Application |

|---|---|

| Construction | Waterproofing membranes under slabs |

| Infrastructure | Tunnels, culverts, bridge joints |

| Industrial | Tank liners, equipment seals |

| DIY & repairs | Gutter and flashing patching, RVs |

Its versatility and longevity make it a trusted solution in both large-scale infrastructure and small residential projects.

Advantages Over Other Synthetic Membranes

Compared to materials like EPDM, TPO, or PVC, butyl rubber membranes offer distinct advantages in certain conditions:

| Feature | Butyl Rubber | EPDM | PVC |

|---|---|---|---|

| Water vapor permeability | Lower (better barrier) | Moderate | Moderate |

| Adhesion to surfaces | Excellent (self-adhesive) | Requires primer/glue | Often heat-welded |

| UV and ozone resistance | Excellent | Good | Poor to moderate |

| Elasticity and recovery | High | High | Moderate |

| Compatibility with surfaces | Wide range | Limited | Requires clean surfaces |

Butyl rubber membranes are especially favored when air-tight sealing, long-term flexibility, or chemical exposure is part of the challenge.

Storage, Handling, and Installation Guidelines

Proper storage and installation help preserve the membrane’s quality and extend its service life.

Storage:

- Keep in a cool, dry place6 away from direct sunlight

- Store flat or rolled (not folded) to avoid creasing

- Avoid contact with oils, solvents, or adhesives until application

Handling:

- Wear gloves to prevent contamination of adhesive surfaces

- Cut using utility knives or scissors

- Avoid stretching the membrane before installation

Installation Tips:

- Surfaces should be clean, dry, and free from dust or grease7

- Use pressure to ensure good adhesion, especially at edges

- Overlap joints by at least 50 mm (2 inches)8 for sealing

- Compatible with primers and tapes for enhanced bonding if needed

| Do | Don’t |

|---|---|

| Use on dry, primed surfaces | Apply over wet or frozen materials |

| Store indoors in original wrap | Expose to UV before installation |

| Apply pressure evenly | Stretch or overstress the membrane |

Correct installation practices ensure seam integrity, water tightness, and long-term performance.

Conclusion

Butyl rubber membrane is a high-performance, low-permeability solution for sealing and waterproofing challenges in a wide range of industries. From roofing to tunneling, its combination of flexibility, chemical resistance, and durability makes it a go-to material when long-term reliability truly matters.

-

Explore how these properties enhance the performance and longevity of butyl rubber membranes in various applications. ↩

-

Learn about the effectiveness of butyl rubber membranes in sealing against moisture and air, crucial for building integrity. ↩

-

Exploring this resource will provide insights into how self-adhesive materials enhance construction efficiency and durability. ↩

-

This link will help you understand the techniques and materials used for effective waterproofing in roofing applications. ↩

-

Discover advanced techniques and materials for vibration control that can improve performance and comfort in vehicles. ↩

-

Explore this link to learn effective storage techniques that maintain material quality and longevity. ↩

-

Understanding surface preparation is crucial for successful installations; this resource provides valuable insights. ↩

-

Discover the importance of proper joint overlap in ensuring durability and effectiveness in installations. ↩

One Response