Why Pneumatic Pressure Controllers Are Essential for Reliable Triaxial Results

Reliable triaxial data starts with quiet pressure. I learned this after chasing noisy curves until a good pneumatic controller calmed everything down.

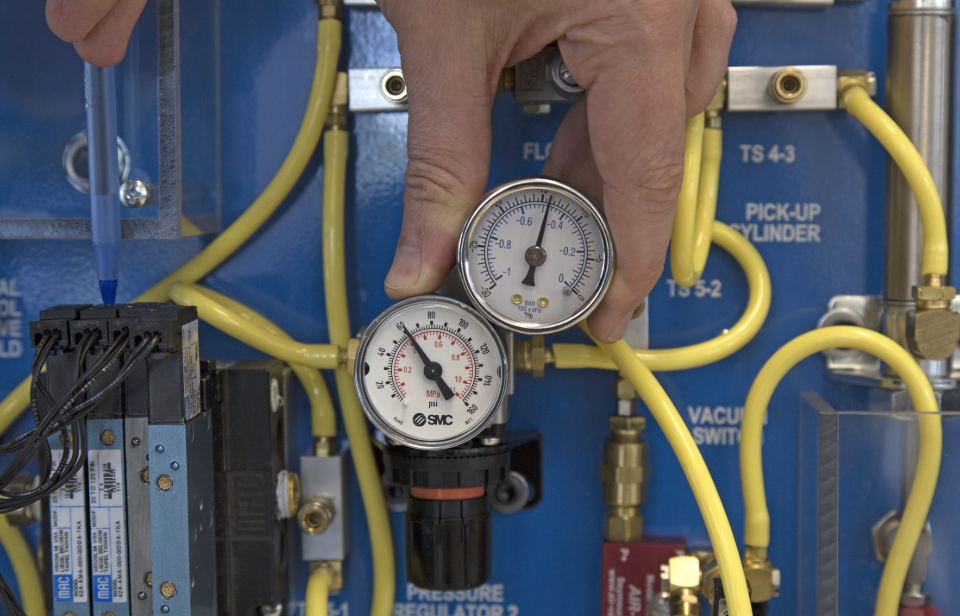

Pneumatic pressure controllers deliver low-overshoot ramps and steady holds for cell and back pressure. That precision protects effective stress, speeds saturation, cleans B-checks, and makes CU/CD stress paths reproducible.

Let’s explore pressure accuracy, human error, saturation with B-value checks, and advanced stress-path control—practically.

Why Do Triaxial Tests Depend on Pressure Accuracy?

If pressure wobbles, effective stress1 lies. Then stiffness, strength, and pore-pressure curves stop reflecting real soil behavior.

Accurate, stable pressure removes fake stiffness and drift. With pneumatics2, targets are hit fast and held quietly, so every data point earns trust.

My first lesson in pressure honesty came from a “strong” clay that wasn’t. A manual regulator overshot by a few kilopascals, then dipped before settling. That tiny dance inflated apparent stiffness and distorted Δu. After we switched to a pneumatic controller with closed-loop feedback, ramps reached setpoint with almost no overshoot, holds went flat, and the stress path relaxed into the shape I expected.

Why accuracy matters to effective stress

Effective stress is ( \sigma’ = \sigma – u ). When σ₃ or back pressure drifts, (p′) and (q) wander, so CU pore-pressure response and CD volumetrics get biased. Stable pressure keeps the path you programmed, not the path your regulator “felt like.” See a quick primer: effective stress basics.

What pressure accuracy fixes

- Fake stiffness from micro-overshoot (air compressing like a spring).

- Hold drift that quietly moves ( \sigma’ ) during saturation or consolidation.

- Noisy k and εᵥ, when head or back pressure wiggles during permeability or drained stages.

A simple diagnostic habit

If plots look anxious—spiky Δu, jumpy modulus—stabilize pressure first. Run a 10–20 kPa hold test and watch volume drift; it reveals leaks and stone issues fast. Grab my hold script: low-pressure hold.

Quick reference

| Item | Manual/weights | Pneumatic |

|---|---|---|

| Ramp behavior | Overshoot/undershoot | Low-overshoot, rate-limited |

| Hold stability | Draft/tech dependent | Active feedback, steady |

| Resolution | Coarse | Sub-kPa (device-dependent) |

| Audit trail | Sparse | Full setpoint/actual logs |

How Do Pneumatic Controllers Reduce Human Error?

Automation turns “good intentions” into repeatable routines. Pneumatics script profiles so different technicians produce the same calm data.

Programmable ramps3, rate limits, interlocks, and auto-logging4 cut setup slips, mistimed valves, and inconsistent pulses—shrinking re-tests and tightening parameters.

Human error hides in tiny moments: a valve opened a beat late, a pulse held a fraction too long, a regulator nudge that seemed harmless. Pneumatic controllers remove most of those moments. I build profiles: saturation steps with capped slew rates, consolidation with pre-checks, and stress-path segments with guardrails. Press start; the controller follows the dance, the same way, every time.

Where errors used to creep in

- Timing slips: hand-pulsed B-checks too slow/large.

- Valve choreography: mis-sequenced lines during saturation.

- Setpoint drift: a “quick tweak” that becomes a 5 kPa bias.

How pneumatics help

- Rate-limited ramps protect soft fabric.

- Interlocks prevent conflicting valve states.

- Scripted pulses standardize Δσ₃ for B.

- Auto-logs time-stamp setpoints and achieved values for audits.

I keep a small “pilot run” ritual: execute a dry profile on a dummy cell to confirm limits, alarms, and sensor calibrations line up. That five-minute rehearsal prevents hours of cleanup. For teams, training becomes clearer: follow the on-screen steps, compare your run to yesterday’s overlay, and if setpoint vs achieved diverges, fix actuation before blaming the soil. Starter templates live here: profile library, rate-limit guide, and valve choreography card.

Error source → pneumatic feature

| Error source | Pneumatic feature | Result |

|---|---|---|

| Pulse inconsistency | Scripted micro-pulses | Clean, repeatable B |

| Late valve action | Interlocks & prompts | Fewer leaks/misroutes |

| Drifting setpoint | Closed-loop control | Flat holds |

| Missing notes | Auto-logging | Defensible reports |

What Role Do Pneumatic Controllers Play in Saturation and B-Value Checks?

Saturation should be calm; B-checks should be boring. Pneumatics make both predictable.

Controllers step back pressure gently, trim cell pressure to keep ( \sigma′ ) tiny, and fire crisp pulses so ( B = \Delta u / \Delta \sigma_3 ) is stable.

My saturation ladder starts with CO₂ → de-aired water to evict bubbles, then back-pressure steps sized to soil type—50–100 kPa for clay, 25–50 kPa for sand. After each step, I lower cell pressure to hold ( \sigma′ \approx 2–5 ) kPa, pause, and watch volume drift. Pneumatic stability keeps those holds flat, so I can read when the specimen is genuinely equalized. If time-to-B stalls, I back-flush porous stones and check fittings before blaming the soil. Quick guides: de-air workflow, saturation step card.

For the B-check, precision matters. A small, fast +Δσ₃ (e.g., +20 kPa) and an immediate Δu reading give a clean B. Scripted pulses remove “tech style” from the measurement. I run two identical pulses; matching B means proceed, drift means find the leak or bubble. A tiny anecdote: one stubborn program hovered at B ≈ 0.93 until we replaced a porous stone that looked fine. With a scripted pulse, B locked at 0.98 twice; CU paths finally overlaid. Pulse and stone care notes: pulse hygiene, porous stone guide.

Targets & actions

| B range | Meaning | Action |

|---|---|---|

| ≥ 0.98 | Excellent | Proceed to consolidation/shear |

| 0.95–0.98 | Good | Proceed; monitor drift |

| 0.90–0.95 | Borderline | Extend holds; clean lines/stones |

| < 0.90 | Not ready | Re-saturate; leak hunt |

I also log time-to-B and hold drift per step; trend lines catch problems early: B-tracker.

Why Are Pneumatic Controllers Vital for Advanced Stress Path Testing?

Advanced paths are choreography: constant-p′, K₀, partial drainage, cyclic. Pneumatics keep channels in sync so paths stay true.

Closed-loop multi-channel control executes constant-p′ and custom paths with minimal lag and overshoot—reducing corrections, phase error, and parameter scatter.

In stress-path work, timing is everything. Constant-p′5 shearing demands that σ₃ and back pressure move together as axial stress changes; any lag nudges p′ off target and smears the curve. Pneumatic controllers coordinate channels so p′ holds while q evolves. For K₀ consolidation6, small confinement nudges track the target ratio without bouncing. In partial-drainage studies, precise micro-heads keep gradients gentle so volumetrics are believable. And for cyclic work, scripted waveforms with soft edges avoid pore-pressure shocks that fake Ru build-up.

I use three safeguards. First, a path planner that previews setpoints, device limits, and rates before a specimen ever sees pressure: path planner. Second, rate caps for soft clays to prevent fabric disturbance: rate guard. Third, an audit overlay that fuses controller logs with DAQ so you can prove setpoint vs achieved matched during the odd spike: audit overlay. When we adopted these habits, overlays from different technicians suddenly looked like carbon copies—tight parameters, calmer design meetings.

Common paths & pneumatic moves

| Path | Pneumatic move | Why it helps |

|---|---|---|

| Constant-p′ | σ₃↑ while u_b adjusts | Mean stress fixed, clean q-evolution |

| K₀ loading | Small σ₃ steps | Lateral stress ratio tracked |

| Partial drainage | Micro-head control | Honest εᵥ and k |

| Cyclic biasing | Soft-edge pulses | No pressure shocks/phase error |

Conclusion

Make pressure precise and calm; saturation, B-checks, and stress paths will finally tell the truth.

-

Understanding effective stress is crucial for accurate soil behavior analysis and engineering applications. ↩

-

Exploring pneumatics can enhance your knowledge of efficient soil testing methods and their benefits. ↩

-

Understanding programmable ramps can enhance your automation strategies, ensuring efficiency and consistency in processes. ↩

-

Exploring auto-logging will reveal its benefits in tracking and optimizing automation, leading to better performance and reliability. ↩

-

Understanding Constant-p′ is crucial for mastering stress-path work and ensuring accurate results in geotechnical engineering. ↩

-

Exploring K₀ consolidation will enhance your knowledge of soil behavior under stress, vital for effective engineering solutions. ↩