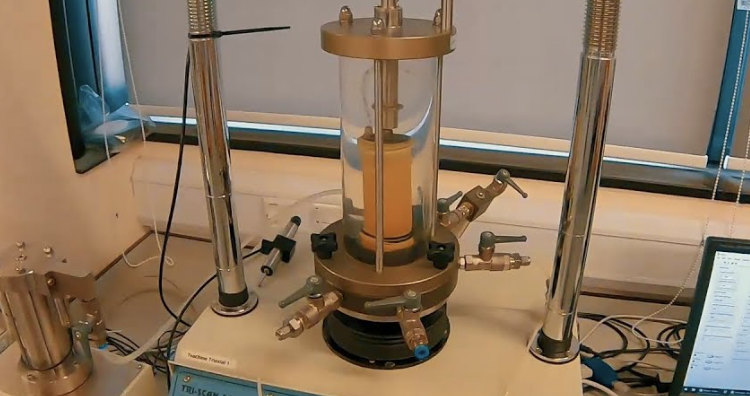

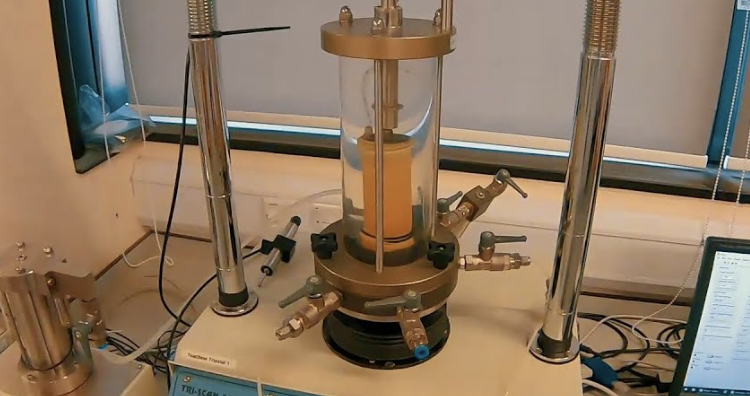

Top 10 Common Challenges in Sample Saturation and How a Triaxial Saturator Solves Them

Saturation looks simple—until bubbles, drift, and tiny leaks wreck your curves. I learned to make it calm, repeatable, and honestly… a little boring.

Quick takeaway: A triaxial saturator fixes ten classic problems: air entrapment, swelling/collapse, shaky B-checks, and uneven saturation. Clean back-pressure steps, upflow plumbing, and short holds turn chaos into clarity.

Let’s map problems to fixes you can run tomorrow.

Overcoming Air Entrapment in Soil Samples

Air hides in pores, lines, and porous stones. If it stays, your stiffness and pore pressures will lie.

In short: Use CO₂ → de-aired water, remove high points, run upflow, and step back pressure with tiny effective stress.

I still remember a clay that “felt strong” until we realized the system was full of tiny springs—air. After a strict CO₂ purge1, re-boiled stones, and upflow through the specimen, the B-value glided upward and the stress path2 finally behaved. Since then, I treat air like the main competitor to truth.

Dive deeper: the top-three air problems (and fixes)

Challenge 1 — Pore-scale air in low-k clays. It compresses, faking stiffness.

Saturator fix: CO₂ displaces air, then de-aired water follows the same path; add long equalization holds. See my CO₂ purge checklist here and de-air routine here.

Challenge 2 — High points in tubing trap bubbles. One raised loop can keep B stuck at 0.90–0.94.

Saturator fix: Re-route lines to remove peaks; switch to upflow through the specimen and crack a micro-bleed valve. My valve map is here.

Challenge 3 — Clogged porous stones hold air. Looks fine, behaves badly.

Saturator fix: Re-boil, back-flush, or swap stones; run a low-pressure hold to confirm near-zero drift. Try the stone care guide here.

Symptom → quick response

| Symptom in plots | Likely cause | Do this first |

|---|---|---|

| Steep early stiffness | Residual air | CO₂ → de-aired water, extend hold |

| B stalls at ~0.92 | Line high point | Re-plumb to upflow; bleed high point |

| Volume drift in hold | Micro-leak/stone | Back-flush stone; swap O-ring |

Small habit that saves days: log time-to-B each step. If it isn’t dropping, air is still winning. My B-tracker is here.

Controlling Swelling and Collapse Risks

Clays can swell if σ′ goes too low; sands can collapse or even pipe if gradients are too high.

In short: Keep effective stress tiny but positive, limit gradients, and use smaller back-pressure steps for sensitive soils.

I treat effective stress like a fragile bridge: enough to stay stable, not enough to distort fabric. For soft clays, I hover at σ′ ≈ 2–5 kPa3 and take 50–100 kPa back-pressure steps with patient holds. For loose sands and silts, I use upflow4 and 25–50 kPa steps, watching for piping cues. One night we chased “random” volume change until we noticed a hungry gradient through a loose sand; we reset the head, and the noise vanished.

Dive deeper: three stability pitfalls (and cures)

Challenge 4 — Clay swelling under near-zero σ′.

Saturator fix: Keep σ′ gently positive while stepping back pressure; use filter papers only when needed to avoid edge bypass. My step planner is here.

Challenge 5 — Sand collapse/piping from aggressive gradients.

Saturator fix: Upflow at low head, smaller increments, sealed system vacuum assist (if rated) before back-fill. See gradient guardrails here.

Challenge 6 — Fabric disturbance from rushing saturation.

Saturator fix: Shorter steps, longer equalization; verify with a low-pressure hold test. Grab the hold script here.

Soil-specific guardrails

| Soil | Step size | Special caution | Quick test |

|---|---|---|---|

| Soft clay | 50–100 kPa | Swell if σ′ < ~2 kPa | Long hold, watch ΔV |

| Silt | 25–50 kPa | Edge bypass via filter paper | Compare with/without paper |

| Loose sand | 25–50 kPa | Piping at high head | Upflow; head ≤ few kPa |

If an equalization hold shows near-zero drift, you’re safe to step. If not, fix the process before blaming the soil.

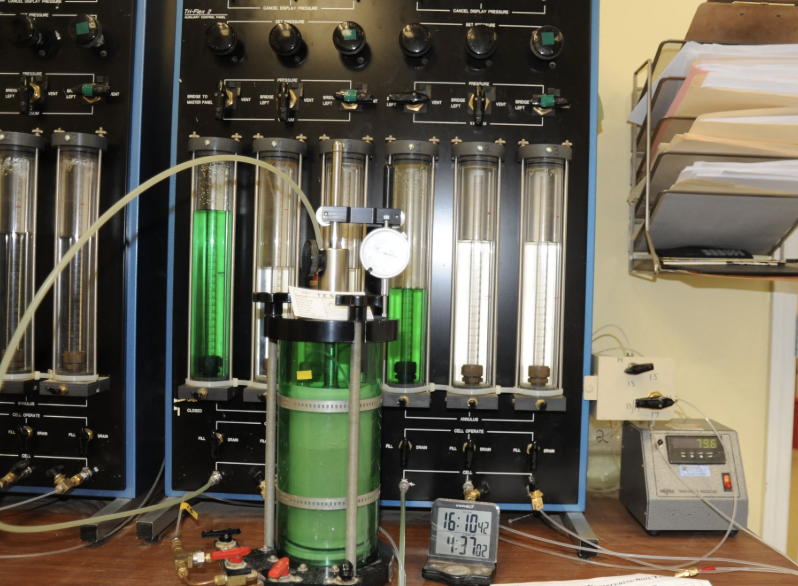

Achieving Reliable B-Value Verification

B is the truth test. If it’s unstable, you don’t know your saturation or your σ′.

In short: Use a small, repeatable pulse; confirm B = Δu/Δσ₃ twice; if it drifts, hunt leaks or stones—not the soil.

I treat B like a traffic light5: green (≥0.98) go; amber (0.95–0.98) pause and note; red (<0.95) fix the setup. I also watch trend: rising B with each hold means you’re close; falling B screams leak. Once, a “perfect” cap O-ring6 was the entire problem—swapped it, B locked at 0.98, and the CU paths lined up like rails.

Dive deeper: two B-check headaches (and solutions)

Challenge 7 — Pulse too big or too slow. Big pulses exceed linear range; slow reads smear Δu.

Saturator fix: Keep pulse small (e.g., ~+20 kPa), record the immediate response, and repeat once. My pulse card is here.

Challenge 8 — B drift between pulses. Thermal effects, micro-leaks, or air in stones.

Saturator fix: Re-boil/back-flush stone, re-seat fittings, confirm temperature stability. Use the drift checklist here.

B-range actions

| B range | Meaning | Action |

|---|---|---|

| ≥ 0.98 | Excellent | Proceed; log value |

| 0.95–0.98 | Good | Proceed; monitor drift |

| 0.90–0.95 | Borderline | Extend hold; clean lines/stones |

| < 0.90 | Insufficient | Re-saturate; leak hunt |

Two pulses, same B? Confidence. Two pulses, different B? Stop—something’s moving that shouldn’t.

Ensuring Stable and Uniform Saturation for All Soil Types

One recipe doesn’t fit all. Clays want time; sands want flow; silts and tailings need gentleness everywhere.

In short: Match step size, flow direction, and holds to soil type; standardize logs so every tech runs the same dance.

Uniform saturation across a mixed program is where labs earn their reputation. I standardize valve choreography7, keep a one-page SOP8 at the bench, and require three numbers on every step: time-to-B, hold drift, and the current σ′. When multiple techs can swap mid-shift and produce indistinguishable B-traces, your lab is ready for big projects.

Dive deeper: the last two consistency challenges

Challenge 9 — Heterogeneity across specimens (uneven saturation).

Saturator fix: Normalize the pathway: upflow, identical stone prep, identical holds; add a quick pre-soak for high fines. See my uniformity SOP here.

Challenge 10 — One-size settings across soils.

Saturator fix: Use a matrix: step sizes, flow, and target holds by soil class; lock it in the LIMS. Matrix template is here.

Saturation settings matrix (starter)

| Soil class | Flow | Step size | Hold length | Notes |

|---|---|---|---|---|

| Sensitive clay | Downflow → Upflow final | 50–100 kPa | Long | Watch swell; σ′ ≈ 2–5 kPa |

| Silt/ML | Upflow | 25–50 kPa | Medium | Avoid edge bypass |

| Fine sand | Upflow | 25–50 kPa | Short | Guard against piping |

| Tailings | Upflow | 25–50 kPa | Medium–Long | Pre-soak; careful head control |

Uniform process beats heroics. Make the run boring; let the data shine.

Conclusion

Tame air, control stress, verify B, and standardize steps—your saturation becomes quiet, and your geotechnical data finally speaks clearly.

-

Understanding CO₂ purging can enhance your knowledge of gas management in various systems. ↩

-

Exploring stress paths can deepen your insight into soil behavior under load, crucial for engineering applications. ↩

-

Understanding this value is crucial for effective stress analysis in geotechnical engineering. ↩

-

Exploring this concept can enhance your knowledge of soil mechanics and improve your engineering practices. ↩

-

Understanding the traffic light system can enhance your project management skills and improve decision-making. ↩

-

Exploring O-ring issues can help you prevent leaks and improve the reliability of your mechanical setups. ↩

-

Understanding valve choreography is crucial for maintaining consistency in lab processes, ensuring high-quality results. ↩

-

A well-crafted one-page SOP can streamline operations and enhance efficiency, making it a valuable resource for any lab. ↩