Factoring in Flowability of Granular Materials: Choosing the Best Lab Equipment

In the world of granular materials—whether you’re working with sand, soil, powders, or pellets—flowability isn’t just a nice-to-know property. It’s a critical factor that influences handling, storage, compaction, and processing. Choosing the right lab equipment for flowability testing helps engineers and scientists predict real-world performance, design better systems, and reduce material handling issues.

Understanding Flowability: A Multidimensional Property

Flowability refers to how easily granular materials move under various forces like gravity, vibration, or pressure. But here’s the catch: it’s not a single number. Flowability is influenced by particle shape1, size distribution2, moisture, cohesion, and surface roughness3.

Flowability Affects:

- Hopper design and discharge

- Soil compaction behavior

- Powder flow in pharmaceutical tablets

- Uniform mixing of construction materials

| Influencing Factor | Effect on Flowability |

|---|---|

| Particle shape | Irregular shapes hinder flow |

| Moisture content | Increases cohesion, reduces flow |

| Size distribution | Wide gradation can lead to bridging |

| Surface texture | Rough particles create friction |

That’s why flowability is considered a multidimensional behavior—and no single test can capture it all.

Key Instruments for Measuring Granular Flow

To properly assess flowability, we rely on several well-established lab instruments. Each offers insight into different flow characteristics under specific conditions.

Common Flowability Instruments:

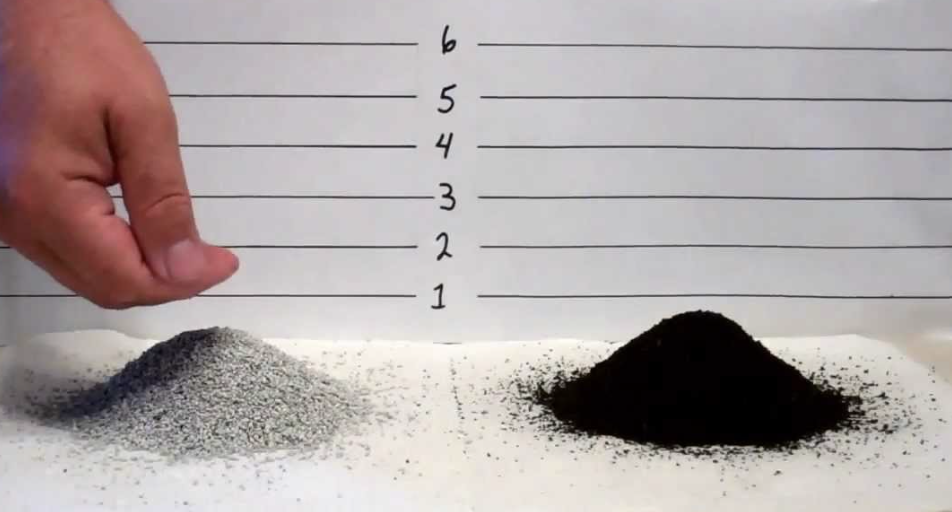

- Angle of Repose Tester4: Measures the steepest angle a pile of material forms without collapsing.

- Flow Funnel5 (e.g., Hall or Carney Funnels): Measures time for material to flow through a known orifice.

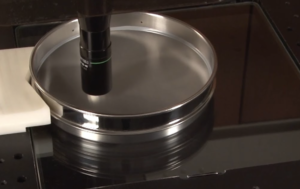

- Shear Cell Tester6 (e.g., Jenike or Ring Shear Tester): Evaluates flow under consolidation and shear.

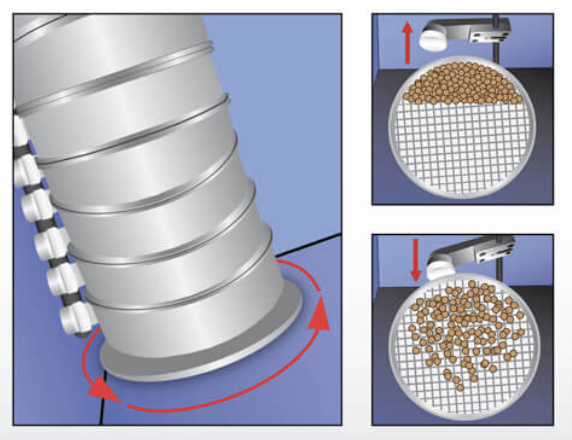

- Tapped Density Apparatus: Indicates how well a material compacts and settles under vibration.

| Instrument | What It Measures | Ideal For |

|---|---|---|

| Angle of Repose Tester | Surface friction and cohesion | Sands, granules |

| Flow Funnel | Flow time and consistency | Free-flowing powders |

| Jenike Shear Cell | Yield locus, unconfined flow function | Cohesive or fine powders |

| Tapped Density Tester | Compressibility and packability | Powdered chemicals, fillers |

Different instruments provide complementary insights into flow dynamics and handling risks.

Matching Equipment to Material Type

No single test fits all materials. Selecting the correct equipment depends on material characteristics and the flow challenge you’re trying to solve.

Equipment Matching Guide:

| Material Type | Suggested Equipment | Why |

|---|---|---|

| Free-flowing sand | Angle of repose, funnel tester | Low cohesion, gravity-dominated |

| Sticky clays or fine powders | Jenike shear cell, tapped density | Prone to bridging or caking |

| Pellets or granular fertilizers | Flow funnels, vibrating feeders | Require discharge rate analysis |

| Cementitious materials | Air permeability, shear cell | Sensitive to compaction and air |

Matching the right tool to your material ensures you avoid misleading results and get data you can trust.

Best Practices for Reliable Flow Testing

Getting accurate and repeatable flowability results takes more than just good equipment. It requires disciplined test protocols7 and awareness of environmental influences.

Tips for Consistency:

- Condition samples for moisture and temperature before testing.

- Use standardized procedures8 like ASTM D6393 or ISO 4324.

- Avoid compaction during loading—especially for funnel or angle tests.

- Perform tests in triplicate to minimize outliers.

- Clean equipment between tests to prevent contamination.

| Best Practice | Impact on Results |

|---|---|

| Consistent loading procedure | Reduces variability |

| Environmental control | Prevents humidity-related errors |

| Repetition and averaging | Increases confidence in the data |

Good data comes from good practice. Investing time in consistent handling pays off in reliable, decision-ready results.

Conclusion

Flowability is a core property of granular materials, and choosing the right lab equipment is essential to measure it accurately. From simple angle-of-repose tests to sophisticated shear cell analysis, each method offers insights into how materials will perform in real-world handling and processing. When matched properly to the material and applied with care, these tests form the backbone of reliable design, efficient operations, and long-term durability in engineering and industry.

-

Understanding particle shape is crucial for optimizing flowability in various applications, from pharmaceuticals to construction. ↩

-

Size distribution plays a key role in determining how materials flow, making it essential for industries like food and pharmaceuticals. ↩

-

Surface roughness can significantly influence flow behavior, impacting processes in manufacturing and material handling. ↩

-

Understanding the Angle of Repose Tester can enhance your knowledge of material flow characteristics, crucial for various industries. ↩

-

Exploring Flow Funnels will provide insights into their practical applications in assessing material flow, essential for quality control. ↩

-

Learning about Shear Cell Testers can deepen your understanding of material behavior under stress, vital for engineering and manufacturing. ↩

-

Understanding disciplined test protocols is crucial for achieving accurate flowability results. Explore this link to enhance your testing methods. ↩

-

Standardized procedures ensure consistency and reliability in testing. Discover more about these procedures to improve your testing accuracy. ↩