The Future of Geotechnical Testing: Trends in Lab and Field Automation

When I look at how we used to run geotechnical tests—stopwatches, clipboards, scribbled notes on plastic-covered log sheets—it feels like a different era.

Today, a lot of that work is automated. Tomorrow, even more will be.

The interesting question isn’t “Will geotech testing change?”

It’s “How fast—and what should we be ready for?”

Let’s walk through where we’re heading: from smart labs and real-time sensors, to AI, digital workflows, and eventually robots and cloud-native testing ecosystems.

From Manual Tests to Smart Labs: How Automation Is Reshaping Geotechnics

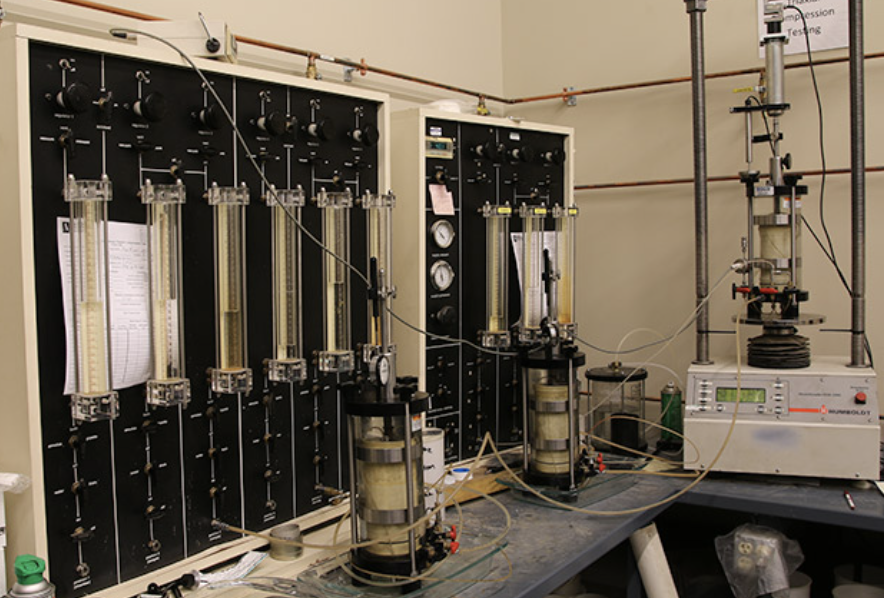

Walk into a modern geotechnical lab and you can feel the difference.

Instead of one technician hovering over a single triaxial frame, you see:

- Fully automated triaxial systems1 running stress paths on multiple samples

- Oedometers that apply load increments and log settlements all night

- Direct shear and permeability rigs quietly cycling through programmed stages

What’s really changed is not just the equipment—it’s the workflow.

Manual era

- Adjust a valve → look at a gauge → write a value → repeat

- One technician = one or two tests at best

- Data lives in notebooks and gets copied (with typos) into spreadsheets later

- Pressures, loads, and displacement controlled by software

- One technician can supervise many tests in parallel

- Data is logged automatically, with time stamps and metadata

The benefits are pretty clear:

- Consistency: machines don’t “have a bad day” the way humans do

- Traceability: every test step is recorded, not just a few key readings

- Capacity: labs can handle more samples without burning staff out

But the big shift is this: the lab technician is less of a “button-pusher” and more of a test designer and quality guardian. Automation handles the routine. Humans protect the meaning.

Real-Time Data, Smart Sensors, and AI: Inside the Next Generation of Geo-Testing

On the field and monitoring side, sensors have gone from “nice-to-have” to “core part of the design feedback loop.”

We’re seeing three big moves:

1. Real-time, networked instruments

Instead of visiting site once a week to read a piezometer or inclinometer, we now have:

- Automated dataloggers3 wired to vibrating wire or MEMS sensors

- Wireless nodes sending readings to the cloud every few minutes or hours

- Dashboards showing live pore pressure, settlement, tilt, strain, or displacement

That means:

- Faster detection of “something’s not right”

- Less time and cost spent on manual readings

- Better comparison between predicted vs observed4 performance

2. Smart sensors and integrated packages

We’re moving from single-value sensors to integrated systems, e.g.:

- A CPT rig with real-time qc, fs, u, plus seismic (SCPT) and possibly resistivity

- Slope monitoring with radar, GNSS, tiltmeters, and pore pressure feeding the same system

- Foundations instrumented with strain gauges, load cells, and temperature all reporting together

The idea is simple: instead of one instrument, you get a picture of ground behavior.

3. AI and pattern recognition

This is still early, but you can already see AI being used to:

- Flag anomalies in long-term monitoring data (e.g. slope movements, dam seepage)

- Classify CPT or DMT profiles into soil behavior types automatically

- Help fit models or pick parameters in lab tests more consistently

AI won’t replace ground engineering judgment anytime soon, but it will:

- Highlight what needs a human’s attention first

- Reduce time spent scanning through huge datasets

- Suggest patterns we might not see at a glance

Think of AI as a very fast junior who never sleeps—but still needs supervision.

Linking Field and Lab: Digital Workflows for Modern Geotechnical Projects

For years, field data and lab data lived in different worlds:

- Logs and CPTs in one pile

- Triaxials, oedometers, and index tests in another

- Design calculations in yet another

We’re now moving towards joined-up, digital workflows5 where:

-

Investigation planning

- Borehole and CPT locations planned in GIS or BIM tools

- Sampling strategy and test schedules generated digitally

-

Data capture in the field

- Borehole logs done on tablets with standardised formats

- CPT rigs streaming data straight into project databases

- Photos and notes geotagged and linked to specific locations/layers

-

Lab integration

- Samples barcoded; chain of custody recorded

- Lab results linked automatically to sample IDs and locations

- Test data flows into the same database as CPTs and logs

-

Design and reporting

- Ground models built from combined field + lab datasets6

- Parameters extracted directly into design tools

- Reports generated from a central data source instead of five disconnected Excel files

This is where automation quietly saves the most time and pain:

- Less manual copying

- Fewer version-control nightmares

- Easier updates when new or revised data arrives

In short: the future is not just automated tests, but automated data flow.

Robots, Cloud Platforms, and Beyond: Where Geotechnical Testing Is Heading Next

If we keep following the current trends, here’s where I think we’re heading.

1. Robotic and semi-autonomous investigation

We’re already seeing:

- CPT rigs that can operate with minimal human intervention

- Drones doing photogrammetry and LiDAR for slope and site mapping

- Autonomous or remotely operated vehicles in offshore and nearshore work

It’s not hard to imagine:

- Robotic sample handlers7 in labs, loading specimens into frames

- Small “geo-rovers8” performing shallow tests in areas that are hard or unsafe for people

- Systems that run standardised test sequences overnight with minimal human presence

2. Cloud-native geotechnical platforms

Instead of each project living in its own set of spreadsheets and local drives, we’ll see:

- Central platforms where boreholes, CPTs, lab tests, monitoring, and models all connect

- Real-time collaboration between field crews, lab staff, designers, and contractors

- API connections between software—no more re-exporting the same data 10 times

In practice, that could look like:

- Updating a test result in the lab, and seeing design parameters update automatically

- Monitoring data triggering automated checks against design assumptions

- Entire ground models living as digital twins, refreshed by new data over the project life

3. Smarter test design, fewer redundant tests

As data and models get better connected, we can:

- Identify where we really need additional tests (and where we don’t)

- Adjust investigation programmes in real time based on early findings

- Reuse proven correlations and knowledge from past projects more effectively

The long-term direction is: better decisions with fewer, more targeted tests, not just “more testing because we can.”

Conclusion: The Future Is Automated—But Not Autopilot

The future of geotechnical testing is clearly moving towards:

- Smart labs instead of manual rigs

- Real-time sensors and AI instead of occasional manual readings

- Digital workflows instead of scattered spreadsheets

- Robots and cloud platforms instead of isolated machines and files

But even in the most automated version of this future, one thing doesn’t change:

Someone still has to build a ground model, judge the data, and take responsibility for the design.

So my take is simple:

- Let automation handle the repetition.

- Let software manage the data flow.

- Save your time and brain for what really matters in geotechnics:

understanding the ground, anticipating how it might surprise you, and designing in a way that keeps people safe.

That part isn’t going away—and honestly, that’s the part that makes this job worth doing.

-

Explore how fully automated triaxial systems enhance efficiency and accuracy in geotechnical testing. ↩

-

Discover the innovations and advantages of the smart lab era that revolutionize geotechnical workflows. ↩

-

Explore this link to understand how Automated dataloggers enhance efficiency and accuracy in data collection. ↩

-

This resource will provide insights into comparing predicted and observed performance, crucial for effective project management. ↩

-

Explore this link to understand how integrated digital workflows can enhance efficiency and collaboration in data management. ↩

-

Discover the benefits of merging field and lab datasets for better decision-making and streamlined processes. ↩

-

Explore how robotic sample handlers can enhance efficiency and accuracy in lab operations. ↩

-

Learn about the innovative applications of geo-rovers in challenging environments for geological testing. ↩