Why Choose Urethane Rubber Sleeves for Hoek Cell Testing? Advantages and Applications

I like tools that stay quiet under pressure. Urethane sleeves do that—seal cleanly, resist tears, and keep rock results honest.

Urethane sleeves balance toughness, elasticity, and chemical stability. They hold seal under high confinement, minimize membrane effects with tunable thickness, and arrive with consistent, inspectable properties—ideal for Hoek cell routines.

Let’s unpack the material science, sealing details, membrane tuning, and a simple procurement/QA playbook.

Material Science Behind Urethane: Why the Polymer Structure Matters

Urethane’s segmented polymer gives rare mix: elastic recovery, tear resistance, and oil compatibility—perfect for compact, high-pressure Hoek cells.

Soft segments stretch; hard segments carry load. This microphase dance creates sleeves that seal tightly yet flex smoothly without cracking.

Polyurethane elastomers are segmented polymers1: “soft” polyol segments joined by urethane linkages and “hard” segments from diisocyanates/chain extenders. Under load, soft domains uncoil for elastic stretch, while hard domains act like physical crosslinks, sharing stress and resisting tear propagation. That’s why a good urethane sleeve can ride fast confining ramps without nicking or whitening.

Microphase separation also influences Shore A hardness2 and stress relaxation. More hard segment content → higher hardness and heat resistance; too much → added membrane stiffness that sneaks into small-strain data. For Hoek cells, we want a middle path: enough hard domain to stop cuts at cap edges, enough soft domain to track radial strain evenly. Urethane’s hysteresis is low enough that holds stay flat, yet high enough to damp tiny pressure spikes—useful when pumps step quickly in compact volumes.

Chemically, polyester-urethane often offers good oil resistance; polyether-urethane resists hydrolysis better in wet environments. Match chemistry to your confining fluid and lab climate. Thermal behavior matters too: glass transition (Tg) below room temperature preserves flexibility; near-Tg materials feel stiff and add artifactual modulus. In practice, I ask suppliers for DSC notes or a simple modulus vs. temperature curve; if the sleeve “hardens” near 20–25 °C, I avoid it. For a plain-English explainer, see my urethane segment guide and a quick chemistry picklist here.

Property knobs that matter

| Polymer knob | Lab effect | What I choose |

|---|---|---|

| Hard segment fraction | Tear stop vs. stiffness | Mid-level for balance |

| Polyether vs. polyester | Hydrolysis vs. oil | Match fluid & humidity |

| Additives (anti-ozone) | Aging resistance | Yes, for long storage |

Seal Integrity Under High Confinement: Getting the Details Right

Sealing beats strength if you want clean data. Small edges, right O-rings, and gentle holds prevent leaks and sleeve damage.

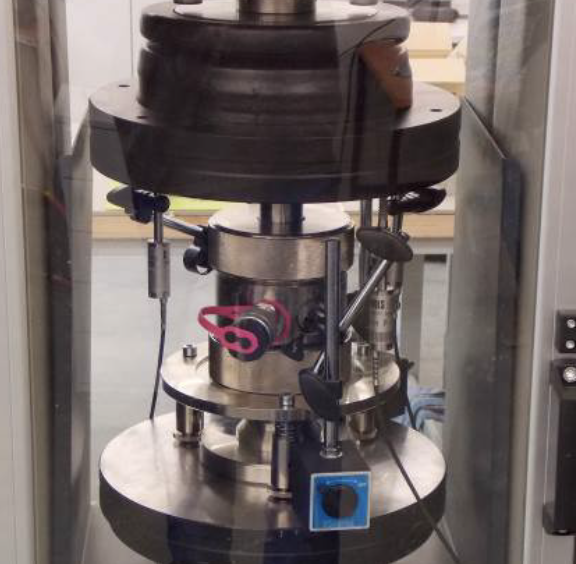

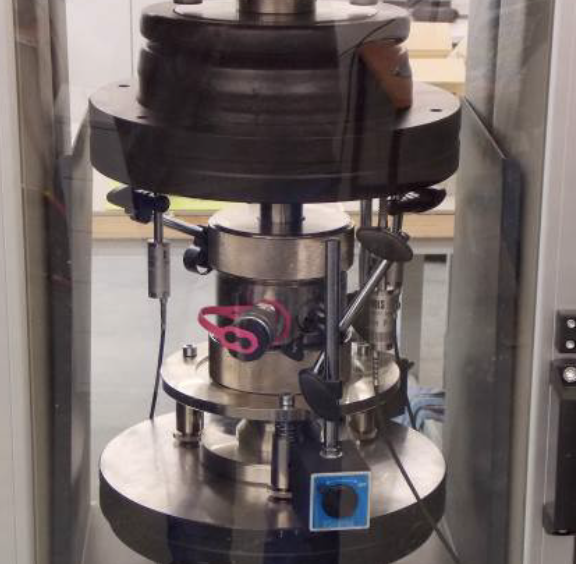

Deburr caps, size sleeves 1–3% undersize, use compatible lube, tighten evenly, and verify with a low-pressure hold before any ramp.

A perfect polymer still fails with sloppy sealing. Start with end-cap geometry3: add a small radius at the sleeve seat; sharp edges create initiators for crescent tears. Clean and lightly polish those shoulders. Choose sleeves whose ID is 1–3% smaller than the core; they seat smoothly without wrinkles or pre-stressing the specimen. Over-size invites axial slip; under-size adds stiffness and early cracking.

Use a compatible micro-lube4—a fingerprint-thin film of glycerin or listed oil—to reduce installation shear. Flooding lubricant creates slip planes and O-ring creep. Clamp or O-ring evenly in opposition (cross pattern), watching for uniform imprint. Before real pressure, run a 10–20 kPa hold (2–5 min). Drift near zero? Proceed. Drift or a weep? Stop—check O-ring size, sleeve lip seating, and cap radius. On high σ₃ programs, I add a step-hold preflight (e.g., 0.5→1.0→2.0 MPa) to surface subtle sealing faults.

Chemistry matters: confirm fluid compatibility (no swelling/clouding) and temperature window. Some oils soften polyester-urethane; some water mixes attack unprotected polyester chains over time. Ask for a 72-hour immersion swell table and keep it on file. Finally, photograph the assembly and log setpoint vs. achieved during holds; it becomes your proof that the boundary was quiet. My seal checklist is here; O-ring pairing notes live here.

Quick seal card

| Step | Check | Pass cue |

|---|---|---|

| Edge radius | No burr/knife edge | Fingernail glides |

| Sleeve fit | 1–3% undersize | No wrinkles |

| Clamp force | Even, opposite turns | Symmetric imprint |

| Hold test | 10–20 kPa, 2–5 min | Δp ≈ 0 |

Minimizing Membrane Effects: Tuning Thickness for Accurate Data

Sleeve too thick? Fake stiffness. Too thin? Tears and creep. Tune thickness to pressure and diameter—not guesswork.

Use thinner sleeves for moderate σ₃ and small cores; thicker for big diameters/high σ₃. Keep Shore A mid-range; validate with a membrane-effect check.

Membrane effects show up as inflated small-strain stiffness5 and muted dilation. Thick or hard sleeves resist radial expansion and add parasitic confinement. To tune, start from your core diameter and target σ₃. For 25–38 mm cores at ≤30 MPa, 0.5–0.8 mm sleeves with Shore A 70–80 often keep corrections small while resisting tears. For 38–54 mm cores at 30–60 MPa, 0.8–1.2 mm at Shore A 75–85 is a steady balance. When σ₃ exceeds ~60 MPa or diameters grow beyond 54 mm, move to 1.0–1.5 mm and Shore A 80–90, but verify impact on early modulus.

Run a baseline modulus check6: compare initial tangent modulus against a trusted material or repeat geometry with a thinner sleeve. If the ratio stays high and constant, your sleeve is adding stiffness. Adjust thickness or hardness one step down. Also ensure you didn’t pre-stretch the sleeve during install; over-stretch raises radial tension at zero load. Thermal drift sneaks in too: sleeves that soften at 30–35 °C may creep during long holds; consider air-con limits or a formulation with better heat resistance.

For practical tuning, grab my thickness chooser here and the membrane-effect estimator here. Keep a simple lab note: pressure, diameter, sleeve spec, early modulus ratio, and pass/fail comment. Two iterations usually land a calm curve.

Starter matrix (tune locally)

| Core Ø | σ₃ range | Thickness | Shore A |

|---|---|---|---|

| 25–38 mm | ≤30 MPa | 0.5–0.8 mm | 70–80 |

| 38–54 mm | 30–60 MPa | 0.8–1.2 mm | 75–85 |

| ≥54 mm | ≥60 MPa | 1.0–1.5 mm | 80–90 |

Procurement & QA: Batch Control, Inspection, and Storage Protocols

Great sleeves start with great batches. Control paperwork, sample tests, and storage—or pay in re-tests.

Ask for batch traceability, thickness/durometer maps, 72-hour swell data, and cure dates. Inspect samples, run a short hold/ramp, and store sleeves dark and cool.

I treat sleeves like consumables with QA teeth7. Before buying big, request: (1) Spec sheet (thickness ± tolerance, Shore A, temp window), (2) Batch map (thickness across positions for 10 pcs), (3) 72-hour immersion/swelling in your confining fluid with mass/size change, (4) Cure date and lot. Ask for two contactable references. Then test 6–10 samples: micrometer at six points, one low-pressure hold (0.2 MPa, 5 min), and a step-hold (0.5→1.0→2.0 MPa). Any weep or drift? Reject or re-spec.

On receipt, label and log by batch/lot, add a FIFO8 rule, and store dark, cool, ozone-free (away from motors). For medium/long storage, sealed UV bags with desiccant help. Run a tiny incoming inspection: measure thickness (mean/SD), quick durometer check, and one dummy hold test. Keep pass/fail thresholds: e.g., thickness SD ≤ 0.03 mm, Shore A ±3, swell ≤ 3% @ 72 h. If any parameter fails, quarantine that batch.

Finally, write a retention note: keep two sleeves per batch as retain samples for 12 months. It saves arguments if results shift later. Download my incoming QA sheet here, storage SOP here, and supplier scorecard here.

Incoming QA snapshot

| Check | Target | Action if fail |

|---|---|---|

| Thickness SD | ≤ 0.03 mm | Quarantine batch |

| Shore A | ±3 of spec | Re-test, then quarantine |

| 72 h swell | ≤ 3% | Reject or change chemistry |

| Hold drift | ≈ 0 at 0.2 MPa | Re-seat; if persists, reject |

Conclusion

Pick urethane, seal cleanly, tune thickness, and police batches—your Hoek cell results will stay calm and credible.

-

Understanding segmented polymers can enhance your knowledge of material science and their practical uses in various industries. ↩

-

Exploring Shore A hardness will provide insights into material properties crucial for selecting the right elastomers for specific applications. ↩

-

Understanding end-cap geometry is crucial for improving sealing performance and preventing failures in polymer applications. ↩

-

Exploring compatible micro-lube options can enhance installation efficiency and reduce the risk of damage during the sealing process. ↩

-

Understanding inflated small-strain stiffness is crucial for optimizing material performance in engineering applications. ↩

-

A baseline modulus check is essential for ensuring material integrity; explore this link for detailed testing methods. ↩

-

Understanding QA teeth can enhance your knowledge of quality assurance in manufacturing, ensuring better product outcomes. ↩

-

Exploring FIFO will help you grasp effective inventory management techniques, crucial for maintaining product quality and reducing waste. ↩