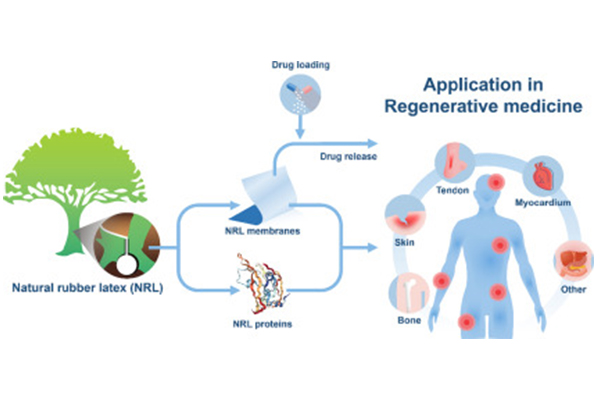

Custom-shaped latex membranes are transforming the medical device industry by offering precision, flexibility, and biocompatibility. These membranes provide solutions that standard options cannot, making them essential in applications like vascular simulators, wound dressings, and prosthetic components. This article explores the role of custom latex membranes in medical innovation, their key applications, advantages, and selection criteria.

Why Custom-Shaped Latex Membranes Are Essential for Medical Innovation

Custom-shaped latex membranes are designed to meet the specific requirements of medical applications. Unlike off-the-shelf membranes, they can be tailored for:

- Enhanced Biocompatibility1: Processed to be safe for direct or indirect contact with the human body.

- Precision Fit2: Designed to match complex anatomical structures, improving performance in medical devices.

- Greater Flexibility and Elasticity3: Provides superior stretch and adaptability compared to standard synthetic options.

- Improved Durability: Custom membranes last longer, reducing the need for frequent replacements.

These features make custom latex membranes indispensable in medical innovation, enabling the development of more advanced and patient-friendly devices.

Key Applications of Custom Latex Membranes in Medical Devices

Custom-shaped latex membranes4 are widely used in various medical fields. Their unique properties make them suitable for:

Vascular Simulators and Hemodynamic Models

- Mimics Realistic Artery Behavior: Custom membranes replicate the elasticity of blood vessels, providing accurate hemodynamic testing.

- Enhanced Visualization: Transparent latex membranes allow direct observation of fluid flow and stent behavior.

- Durable for Repeated Use: Used in medical training to practice catheter insertions, aneurysm repairs, and microvascular surgery.

Prosthetic Components and Biomedical Implants

- Flexible and Adaptive: Provides soft, elastic coverings for prosthetics, improving user comfort.

- Biocompatibility5: Processed latex reduces the risk of irritation or allergic reactions.

- Seamless Integration: Used in heart assist devices and other implants requiring flexible, durable components.

Wound Dressings and Healing Biomembranes6

- Encourages Faster Healing: Latex biomembranes promote angiogenesis and tissue regeneration.

- Protective and Breathable: Acts as an effective wound cover, maintaining an optimal healing environment.

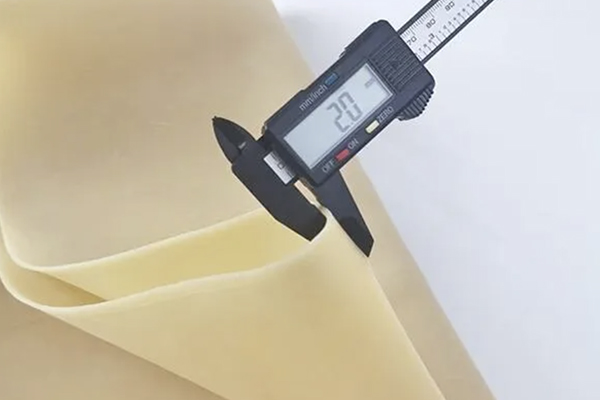

- Custom Thickness Options: Thin membranes for delicate areas, thicker ones for pressure ulcer treatment.

Surgical Training Models

- Realistic Tissue Simulation: Used in suturing and microsurgery practice.

- Cost-Effective Training: Provides a reusable alternative to animal tissues for surgical education.

- Custom Cut for Specific Procedures: Simulates different tissue types, allowing for precise surgical technique training.

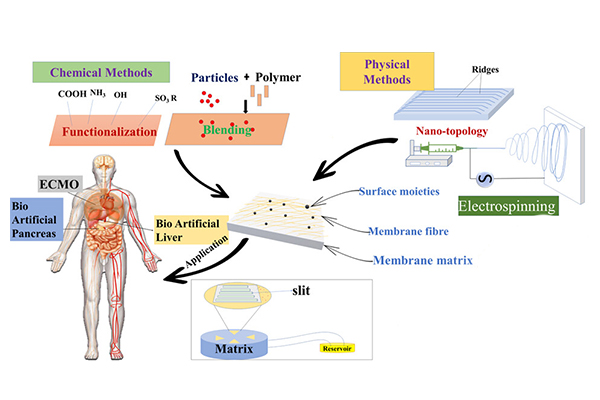

Advantages of Custom-Shaped Latex Membranes Over Standard Options

Custom latex membranes outperform generic options in critical aspects such as flexibility, longevity, and performance.

Performance Comparison of Standard vs. Custom Latex Membranes

| Feature | Standard Membranes | Custom-Shaped Latex Membranes |

|---|---|---|

| Elasticity & Flexibility | Limited stretch, may tear easily | High stretchability (>700%) and durability |

| Precision Fit | May not conform to specific shapes | Tailored to match exact anatomical structures |

| Transparency | Opaque or semi-transparent | Fully transparent options available for observation |

| Durability | Can degrade over time | Long-lasting and reusable in medical devices |

| Biocompatibility | May require extra coatings | Medical-grade latex with hypoallergenic processing |

Custom latex membranes provide superior elasticity, durability, and precision fit, making them ideal for demanding medical applications.

Choosing the Right Custom Latex Membrane for Your Medical Device

When selecting a custom latex membrane, consider the following factors:

Key Selection Criteria for Custom Latex Membranes

| Application | Recommended Thickness | Elasticity Requirements | Biocompatibility Needs |

|---|---|---|---|

| Vascular Simulators | 0.1–0.5 mm | High flexibility, mimics arteries | Medical-grade, transparent |

| Prosthetic Covers | 1–2 mm | Moderate, must conform to movement | Hypoallergenic latex |

| Wound Dressings | 0.1–0.3 mm | Low, must remain stable on skin | Deproteinized for safety |

| Surgical Models | 0.5–1 mm | High elasticity, withstands suturing | Standard medical latex |

- Thickness: Thinner membranes for applications requiring flexibility (e.g., vascular models), thicker ones for durability (e.g., prosthetic covers).

- Elasticity: Higher elasticity is crucial for dynamic applications like vascular simulation and surgical training.

- Biocompatibility: Use hypoallergenic latex for patient-contact devices to minimize allergic reactions.

Conclusion

Custom-shaped latex membranes offer unparalleled versatility in medical device innovation. By providing superior flexibility, durability, and precision fit, they enable more realistic surgical models, more effective wound care solutions, and better-performing biomedical implants. Their ability to be tailored to specific medical needs makes them essential for advancing healthcare technology.

As the demand for highly specialized medical devices grows, custom latex membranes will continue to play a pivotal role in enhancing patient outcomes, improving medical training, and pushing the boundaries of biomedical engineering.

-

Explore how Enhanced Biocompatibility can improve patient safety and device performance in medical applications. ↩

-

Learn about the importance of Precision Fit in enhancing the effectiveness of medical devices tailored to individual needs. ↩

-

Discover how Greater Flexibility and Elasticity contribute to the adaptability and comfort of medical devices for patients. ↩

-

Explore how custom-shaped latex membranes are revolutionizing medical training and device development with their unique properties. ↩

-

Understanding biocompatibility is crucial for ensuring patient safety and comfort in medical devices and implants. ↩

-

Discover the role of advanced wound dressings in promoting healing and protecting injuries effectively. ↩