Sizing membranes isn’t guesswork—it’s matching inner diameter1, wall, and stretch to your specimen.

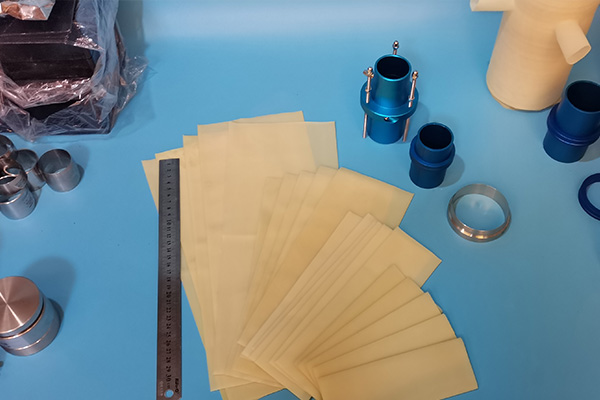

For 38, 50, 70, and 100 mm samples: choose a snug ID, the right thickness for D50 and σ₃2, and verify fit with a quick dummy mount3.

Here’s the simple way I pick sizes—fast, reliable, repeatable.

What do triaxial sample dimensions really mean?

Length, diameter, and ovality4 tell me how a membrane must fit—without folds or over-stretch.

I measure diameter at three heights, check L/D5≈2.0–2.5, and confirm roundness; this prevents wrinkles, leaks, and false volume change.

Dive deeper: translating specimen geometry6 into membrane choices7 (200+ words)

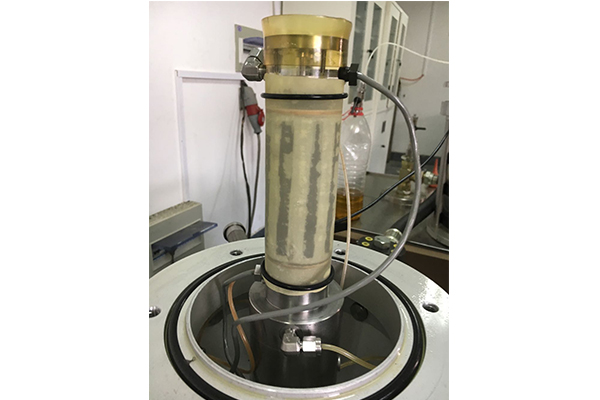

Before I touch a membrane, I map the specimen: top, mid, and bottom diameters; average and ovality4 (max–min). If ovality4 is large, even a perfect membrane will crease. I trim to a uniform cylinder first. Length matters too—L/D5 ≈ 2.0–2.5 keeps stress distribution tidy and reduces end effects.

I also note particle size (D50) and angularity. Fine clays accept thinner walls; sands and sharp grains need thicker walls for durability. Finally, I log intended σ₃2. Higher confining stresses push me toward a sturdier wall to limit mid-height bulging.

This simple map—Ø, L/D5, ovality4, D50, σ₃2—drives everything. With it, I can choose a snug inner diameter1 (ID) that slides on with light vacuum but doesn’t bunch. If I’m between sizes, I test both on a dummy cylinder for 30 seconds under gentle vacuum. The one that seats wrinkle-free, without over-stretch, wins.

For quick reminders, I keep a tiny checklist card in the lab: specimen-sizing notes.

| Dimension | Why it matters | What I do |

|---|---|---|

| Ø (three heights) | Detect taper/ovality4 | Trim or re-core |

| L/D5 | Stress uniformity | Target 2.0–2.5 |

| D50, angularity | Wall durability | Thicken for sand |

| σ₃2 target | Bulging risk | Step wall up one grade |

How do I match membrane size to sample diameter?

Think ID≈OD (snug), not tight. Then pick thickness by soil and stress.

For 38/50/70/100 mm, choose the closest ID band that seats wrinkle-free under moderate vacuum; never rely on stretch to “make it fit.”

Dive deeper: size bands and thickness by diameter (200+ words)

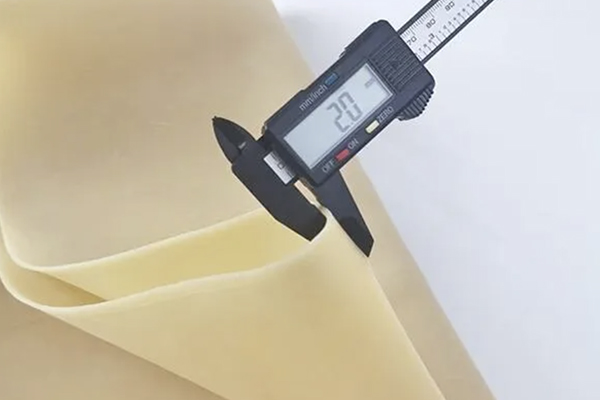

I keep two ID bands for each specimen diameter: snug and slightly roomier. Snug is my default; the roomier band saves me when a core is a hair over nominal. Thickness follows soil and σ₃2: clays like 0.30–0.35 mm at small diameters, while sands prefer 0.45–0.60 mm (or more at big Ø or high σ₃2).

Mounting is my referee. If a “snug” ID needs aggressive vacuum, it’s too small; over-stretching thins the wall at mid-height and invites tears. If the “roomier” ID sits with zero folds after a gentle vacuum, that’s my pick.

Below are rules that get me >90% first-time fits. I still run a 60-second bubble check—cheap insurance: fit & bubble checklist.

| Specimen Ø | Recommended Membrane ID Band | Typical Wall (clay) | Typical Wall (silt/silty clay) | Typical Wall (fine sand) |

|---|---|---|---|---|

| 38 mm | 38–39 mm snug / 39–40 mm alt | 0.30–0.35 mm | 0.35–0.45 mm | 0.45–0.60 mm |

| 50 mm | 50–51 mm snug / 51–52 mm alt | 0.30–0.35 mm | 0.35–0.45 mm | 0.45–0.60 mm |

| 70 mm | 70–71 mm snug / 71–72 mm alt | 0.35–0.45 mm | 0.45–0.55 mm | 0.60–0.80 mm |

| 100 mm | 100–101 mm snug / 101–102 mm alt | 0.35–0.45 mm | 0.50–0.60 mm | 0.70–0.90 mm |

High σ₃2 (>400 kPa) or very angular grains? Add +0.05–0.10 mm to the wall guideline.

How do elasticity and fit affect accuracy?

Elasticity helps mounting—but too soft or too stiff can bias results.

Use elasticity that seats without over-stretch; too soft encourages folds, too stiff raises radial restraint and mutes dilation and u-excess.

Dive deeper: balancing compliance and restraint (200+ words)

A membrane is part of the system stiffness. If elasticity is too soft and the ID is slightly large, folds form. In CD, folds behave like little bladders, faking dilation or compression as pressure changes. In CU, they can trap micro-volumes and blur excess pore pressure.

If elasticity is too stiff, you add radial restraint that inflates apparent strength and can mute the dilation signal. That bias is subtle in UU, but it matters in CU and CD where pore pressure and volume change carry the story.

My compromise: standard natural latex for clays; slightly stiffer blends (or chlorinated latex) for sands and higher σ₃2. I also love transparent membranes—they let me spot bubbles and wrinkles before consolidation starts: transparent-mount tips.

Fit routine I trust:

- Dummy mount (light vacuum, 30 s).

- If chatter lines or micro-folds appear, switch ID band or wall.

- Thin lube only at interfaces (caps/stones), not the full height.

- Bubble test at low cell pressure; aim B ≥ 0.95 in CU.

| Fit factor | Too soft | Just right | Too stiff |

|---|---|---|---|

| Mounting | Easy but wrinkly | Smooth, wrinkle-free | Hard to seat |

| Data risk | False dilation | Clean curves | Muted dilation / higher peak |

What sizing mistakes do people make—and how do I avoid them?

Most errors come from forcing stretch, ignoring ovality4, or picking one wall for all soils.

Avoid undersized IDs, aggressive vacuum, and single-grade walls; measure, choose snug bands, and adjust thickness to soil and σ₃2.

Dive deeper: the greatest hits of sizing regret (200+ words)

Undersized ID = over-stretch. It looks tight and “secure” until a mid-height split ends your day. If you need high vacuum to seat, it’s the wrong ID. Oversized ID = folds. They’re quiet during mounting, noisy in plots. Switch to the snug band or step thickness down if elasticity allows.

Ignoring ovality4 is another trap. A tapered or oval core will wrinkle any membrane. Re-trim or re-core before you waste consumables.

Finally, the one-wall-fits-all myth: it’s convenient, but clays and sands behave differently. Thin walls shine in clays (fidelity), while sands demand thicker, tougher walls.

My fix is boring and effective: two ID bands and two wall grades per diameter; a standard deburring and cleaning habit for caps and stones; and a short leak/bubble test8 every time. These tiny habits saved me from countless reruns: [mounting SOP](https://polyguard.com/blog/waterproofing-membrane-installation)9 and [leak check card](https://www.youtube.com/watch?v=d72t9k8ivFI)10.

| Mistake | Symptom | Quick fix |

|---|---|---|

| Undersized ID | Over-stretch tears | Move to alt ID band |

| Oversized ID | Wrinkles, noisy volume | Drop ID or wall; re-seat |

| One wall for all | Biased peaks/dilation | Match wall to soil/σ₃2 |

| Skipping bubble test8 | Low B, leaks in CU | 60-s low-pressure check |

Conclusion

Measure first, pick a snug ID and honest wall, mount gently—then let your curves tell the truth.

-

Understanding inner diameter is crucial for achieving a proper fit and preventing issues during testing. ↩ ↩

-

Knowing σ₃ helps in choosing the right membrane wall thickness for your samples. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

A dummy mount is essential for testing fit; learn how to use it effectively to avoid errors. ↩

-

Exploring ovality’s impact can help you avoid wrinkles and ensure accurate measurements. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

The L/D ratio is vital for stress distribution; learn how to optimize it for better results. ↩ ↩ ↩ ↩

-

Understanding specimen geometry is key to selecting the appropriate membrane size and type. ↩

-

Choosing the right membrane is critical for accurate results; explore guidelines to make informed decisions. ↩

-

The bubble test is a simple yet effective way to check for leaks and ensure proper fit. ↩ ↩

-

A clear SOP can streamline your process and reduce the risk of errors during membrane installation. ↩

-

A leak check card is a practical tool to ensure your setup is airtight before testing. ↩