I’ve always been amazed by how something as simple as a flexible membrane can play such a big role in modern testing. It’s like discovering that a small puzzle piece can determine the outcome of an entire picture.

Triaxial latex membranes are crucial in various testing procedures because they help simulate real-world conditions, ensuring accurate and reliable results across industries.

I love chatting about the potential these membranes bring, especially when it comes to industrial applications.

What are the practical applications of triaxial latex membranes test?

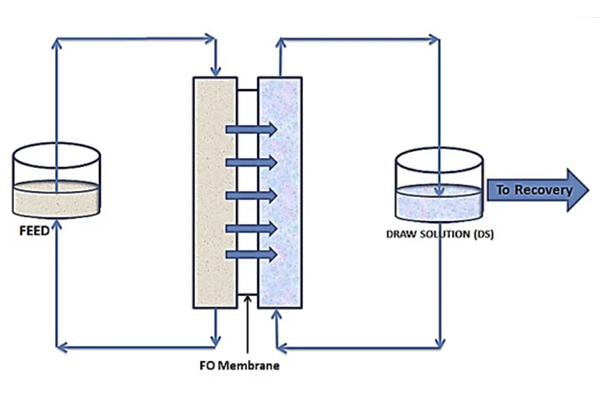

Triaxial latex membranes enable us to study soil and material behavior under different pressures. Sounds simple, but it’s incredibly important.

They are widely used in geotechnical tests to analyze how materials react under stress, guiding safer and more efficient construction methods.

In my early days working with testing labs, I remember being puzzled by how a thin sheet of latex could influence major engineering decisions. One time, I visited a local construction site where they were analyzing soil for a new apartment complex. The engineer told me, “We rely on these membranes more than you’d think—they’re the unsung heroes of geotechnical testing1.” That stuck with me.

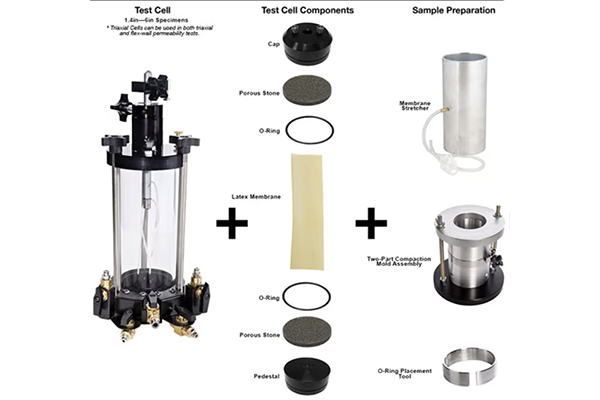

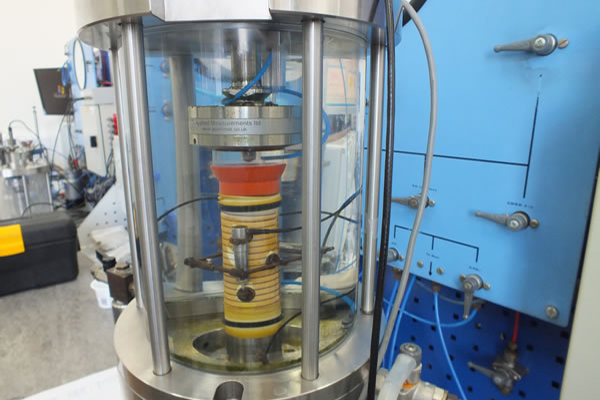

Triaxial latex membranes are primarily used in triaxial tests to figure out how soil behaves when it’s exposed to different stress levels, usually in three directions. This simulates the underground conditions that foundations and other structural elements will face in real-world settings. By containing the soil sample within a latex membrane and applying controlled pressure, engineers can measure changes in volume, shape, and overall structural integrity of the soil.

Beyond soil analysis, these membranes also appear in rock mechanics, where they help test rock core samples for tunnels or large commercial developments. In these cases, a single tear or gap in the membrane can throw off the entire test. That’s why consistent quality matters so much. And that’s also where I’m proud of what we do at Howdy—our membranes aim to minimize risk by maintaining a solid seal and consistent thickness. After all, precision is everything when you’re trying to predict how a massive building or highway will hold up over decades.

Because of these reliable results, triaxial latex membranes2 shape the safety of new constructions, offering peace of mind for engineers, investors, and future occupants alike.

What are the industrial applications of Latex Membrane technology?

Latex membrane technology extends far beyond soil tests. It appears in industries like mining, automotive, and even chemical processing.

These membranes help maintain controlled environments in testing scenarios, ensuring products and materials meet industrial standards and safety requirements.

If you think latex membranes only make sense for soil and rock tests, you’d be pleasantly surprised at how diverse their applications really are. In the mining industry, for instance, these membranes help assess ore samples, providing data on how the material might behave under deep-earth pressures before major excavation. The automotive sector uses membranes for testing rubber components and composite materials—particularly those that need to withstand varying stress levels over time.

I once visited a factory that manufactured specialized parts for heavy-duty trucks. They tested the rubber bushings using a controlled pressure chamber3 that utilized latex membranes to simulate impact and vibration. Without these membranes, controlling the environment inside the test chamber would be nearly impossible. Imagine trying to keep water, oil, or any other fluid away from the tested material without the elasticity and precision of a latex membrane. It would be a mess.

Moreover, latex membranes are essential in laboratories working on new chemical compounds. Sometimes, a substance’s reaction to pressure or confinement can be studied more accurately with the help of a membrane barrier. Even for companies looking to create new building materials, whether that’s advanced concrete mixes or composite panels, latex membranes come in handy for smaller-scale stress tests4, saving them from expensive large-scale trials.

In short, any industry that cares about durability, safety, and performance under stress can benefit from latex membrane technology. And, given our mission at Howdy to provide durable testing solutions, I’m proud to see how these membranes have become a staple in so many fields.

What is the cost of triaxial latex membrane?

Pricing can vary depending on thickness, size, and quality standards. But it’s generally more budget-friendly than many expect.

High-quality membranes can range from a few dollars to higher-tier rates, especially when custom sizes or materials are required.

I’ll be honest: whenever someone asks about cost, I tell them it’s like shopping for a good pair of work boots. Sure, you can go cheap, but you might replace them twice as often. The same logic applies to triaxial latex membranes. When Mr.White from the USA (a regular contact of ours) first inquired about our membranes, he was mostly concerned about balancing quality with price. He told me, “I don’t mind paying a bit extra if it means I get consistent results and fewer test repeats.”

Generally speaking, the cost depends on factors like thickness, diameter, and required durability. If you’re testing standard soil samples in moderate pressure ranges, you could opt for an economical batch. But if you need a membrane that withstands intense pressure variations—or you’re conducting advanced research at a university-level lab—investing in a higher-grade membrane could save you from inaccurate data or frequent replacements.

In my experience, serious testing labs5 or large corporate buyers prefer buying membranes in bulk, which often secures a better price per unit. At Howdy, we focus on wholesale, so big orders naturally come with discounted rates. Plus, we have a design department for special requirements, which might cost a bit more but can be crucial for unique testing setups. I’ve seen labs spend extra on membranes only to recoup the cost through fewer test failures down the line. So, while cost is always a concern, it’s worth remembering that in the world of precise testing, reliability often pays for itself.

What is the triaxial test used for?

The triaxial test evaluates how materials, especially soils, behave under controlled stress in all directions.

Engineers use this test to determine shear strength, compressibility, and overall stability of materials for safer designs.

I recall the first time I watched a triaxial test in a university lab. It felt like peeking into a miniature world where the soil sample was the star of a pressure-filled show. If you’ve never seen it, imagine a small cylinder of soil wrapped in a latex membrane and placed in a cell. Then we apply pressure from all sides—like giving the soil a 360-degree hug.

This test is vital because it mirrors the real-world conditions a material might face underground. When engineers plan huge projects—whether it’s a new skyscraper, a highway, or a bridge—they need to know if the foundation soil can support the weight and handle everyday wear and tear. Through triaxial testing, they find out the soil’s “breaking point,” or in more technical terms, its shear strength6.

Besides construction, the test is also key for analyzing potential landslides or slope failures. I once worked with a geologist who used triaxial tests to examine hillside stability7 near a residential area. Thanks to accurate data, they managed to implement reinforcements before any disaster struck. The test essentially saves time, money, and, most importantly, lives. At Howdy’s official site, I like to share stories like these to highlight why we put so much care into making durable membranes. After all, the test is only as reliable as the quality of the membrane—and the data it helps gather.

Conclusion

Triaxial latex membranes open the door to safer designs and deeper material insights across many modern industries.

-

Learn about geotechnical testing and its significance in construction to appreciate the engineering behind safe buildings. ↩

-

Explore this link to understand the critical role triaxial latex membranes play in ensuring the safety and integrity of construction projects. ↩

-

Learn about the technology behind controlled pressure chambers and their significance in material testing, especially with latex membranes. ↩

-

Discover the importance of stress tests in ensuring material durability and safety, and how they can save costs in development. ↩

-

Learn what testing labs prioritize in membrane quality to ensure accurate results, helping you make informed purchasing decisions. ↩

-

Exploring shear strength measurement methods can enhance your knowledge of soil stability and construction safety. ↩

-

Learning about hillside stability factors is vital for preventing landslides and ensuring safety in residential areas. ↩

2 Responses