Common Issues with Vacuum Pumps in Triaxial Testing and How to Fix Them

Vacuum pumps play a crucial role in triaxial soil testing, from membrane mounting to specimen saturation. However, like any precision laboratory equipment, they can encounter performance issues that affect test accuracy. Understanding these problems—and knowing how to solve them—can help maintain efficiency and data reliability.

Why Does Vacuum Pressure Become Unstable?

Unstable vacuum pressure can cause inconsistencies in specimen preparation and pore pressure control during triaxial testing.

Common causes include:

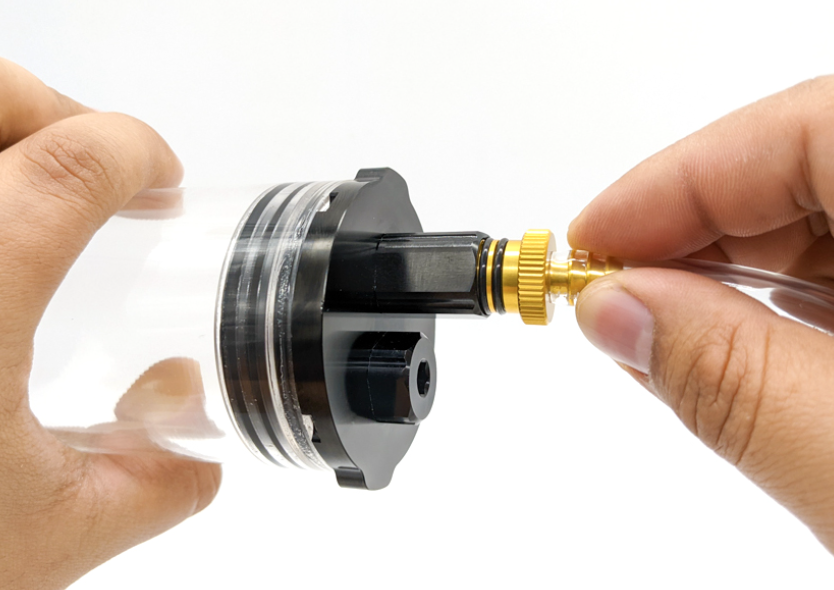

- Leaks in tubing, seals, or fittings

- Faulty check valves or worn gaskets

- Improper oil levels or degraded oil in rotary vane pumps

How to fix it:

- Perform a leak check using soapy water or a vacuum gauge

- Replace worn seals and faulty valves promptly

- Maintain correct oil levels and replace oil on schedule

Why Does the Pump Evacuate Slowly?

A slow evacuation rate1 can delay test setup, reducing lab efficiency.

Possible reasons:

- Partially clogged inlet filters or lines

- Worn vanes or diaphragms inside the pump

- Excessive moisture in the pump chamber

Soluciones:

- Clean or replace inlet filters regularly

- Schedule periodic internal inspections for vane or diaphragm wear

- Use a moisture trap2 to prevent water vapor from entering the pump

How to Reduce Excessive Noise During Operation?

Excessive noise is more than a comfort issue—it can indicate mechanical wear3.

Common causes:

- Loose motor mounts or vibration

- Bearing wear or insufficient lubrication

- Pump operating under excessive load

Remedies:

- Tighten all mounting bolts and use vibration-damping pads4

- Replace worn bearings and lubricate according to the manufacturer’s guidelines

- Avoid overloading the pump beyond its rated vacuum capacity

Why Does Oil Get Contaminated Quickly?

Contaminated oil reduces pump efficiency5 and shortens its lifespan.

Typical causes:

- Moisture carryover from the testing system

- Dust and fine particles from soil samples

- Lack of regular oil changes

How to fix it:

- Install proper filters and moisture traps

- Keep the pump intake away from dust sources

- Follow a strict oil change schedule6 recommended by the manufacturer

Conclusión

Regular maintenance, proper operating procedures, and quick troubleshooting are the keys to keeping vacuum pumps in triaxial testing running smoothly. By addressing pressure instability, slow evacuation, noise, and oil contamination proactively, labs can ensure both accurate results and longer equipment life.

-

Understanding the impact of slow evacuation rates can help improve lab efficiency and setup times. ↩

-

Learning about moisture traps can enhance your knowledge of preventing pump issues and maintaining efficiency. ↩

-

Understanding mechanical wear can help you prevent costly repairs and extend the life of your equipment. ↩

-

Exploring the benefits of vibration-damping pads can enhance your machinery’s performance and reduce noise. ↩

-

Understanding pump efficiency is crucial for optimizing performance and extending equipment lifespan. ↩

-

A regular oil change schedule ensures optimal performance and longevity of your pump, preventing costly repairs. ↩