Hoek Cell vs. Conventional Triaxial Cell: Which Is Better for Rock Testing?

Hoek cells feel rugged and simple; conventional triaxial cells feel flexible and instrument-rich. I use both—and they shine in different fights.

Use Hoek cells for compact, high-pressure, uniaxial/indirect testing of cores with minimal setup. Choose conventional triaxial cells when you need rich instrumentation, true triaxial paths, drainage options, and detailed stress–strain–pore pressure data.

Let’s compare differences, winning cases, accuracy/pressure head-to-head, and a no-nonsense buying checklist.

What Makes a Hoek Cell Different?

A Hoek cell is compact, strong, and fast to use—perfect for high-pressure strength checks with simple instrumentation.

Hoek cells prioritize pressure capacity and simplicity over sensors: great for confined strength and modulus snapshots, less ideal for pore pressure or complex stress paths.

When I need a quick, confident read on rock strength under high confining pressure, a Hoek cell1 keeps life simple. The body is stout, the specimen jacket path is short, and setup time is small. Because the geometry is compact, the hydraulic volume is low—pressure ramps feel snappy and stable. That’s a gift when I’m screening multiple cores in a long day.

But the same simplicity that makes it fast also limits sensors. Most Hoek setups don’t support full pore pressure measurement, radial strain gauges, or custom drainage routes. You’ll often capture axial load/displacement2 and confining pressure, then compute strength and tangent modulus. If your question is “What’s the strength envelope across pressures?”—great. If your question is “How does pore pressure evolve or how does anisotropy affect dilation?”—you’ll miss detail.

I think of a Hoek cell as a rock brawler: compact frame, hits hard, little chatter. If you add strain gauges or external LVDTs with careful fixtures, you can widen the story a bit—but it’s still best at efficient, repeatable strength indexing across pressure steps. For a clean orientation guide and jacket tips, see my core prep notes here and seal checklist here. For fast pressure routines, my ramp card is here.

Where Hoek cells excel

- High confining pressure snapshots

- Screening multiple cores quickly

- Facilities with limited DAQ channels

- Rugged field or compact lab setups

When Does a Conventional Triaxial Cell Win?

When I need instrumentation and control, a conventional cell wins—pore pressure, drainage, strain paths, and anisotropy studies.

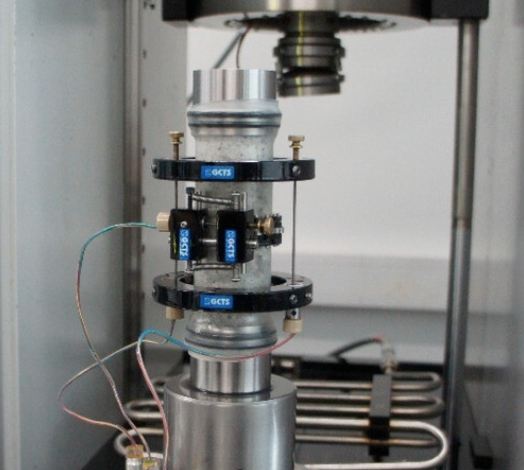

Conventional triaxial cells support pore pressure transducers, bender elements, local strain, drainage choices, and sophisticated stress paths—ideal for research and design-grade parameter sets.

Research questions rarely stop at “how strong.” I often need pore pressure evolution, dilation angles3, elastic/plastic moduli, or responses under constant p′, K₀, or cyclic paths. Conventional triaxial rigs let me wire pore pressure, radial/axial local strains, and even acoustic sensors. With pneumatic controllers driving cell and back pressure, I can hold gentle heads for drained tests, run undrained CU paths, or step through partial drainage sequences. That instrumentation translates into design-grade parameters4: cohesion–friction fits with confidence bands, stiffness degradation curves, and time-dependent behavior.

Yes, setup is slower. More seals, more lines, more chances for tiny leaks. But once it’s tight, I get rich, layered data: q–ε, p′–q, Δu–ε, volumetric strain, even wave velocity if I add bender elements. For anisotropic or transversely isotropic rocks, I can rotate cores, install local strain rings, and observe fabric-controlled behavior—not just a single peak. If I need to defend a design in front of a tunneling board or dam review panel, that extra sensing often pays for itself. Setup SOPs and leak checks save me from regret: valve choreography here, pore line flushing here, and sensor zeroing here.

Conventional triaxial wins when you need

- Pore pressure, drainage, and effective stress stories

- Local strain and stiffness evolution

- Custom stress paths (constant p′, cyclic, K₀)

- Publication-grade data and defensible design inputs

Accuracy, Pressure Range, and Instrumentation: Head-to-Head

Side-by-side matters. Here’s how I frame range, accuracy, sensors, and throughput when choosing.

Hoek: higher practical pressure with simpler setup. Conventional: richer sensors and stress-path control. Pick based on question, pressure, and data depth.

I keep a small matrix to stop arguments and start decisions. It compares pressure capacity, accuracy, sensor options, throughput, and learning curve. The goal isn’t to crown a champion; it’s to match the tool to the question. If your program is a fast strength envelope across rock types—go Hoek. If your program feeds a numerical model with pore pressure and stiffness laws—go conventional. And if budget allows, a hybrid lab is powerful: screen lots of cores with a Hoek, then send select specimens to the conventional rig for deep dives. For acceptance tests and calibration habits, see pressure verification here and strain chain checks here.

Head-to-head table

| Dimension | Hoek Cell | Conventional Triaxial Cell |

|---|---|---|

| Pressure range | Typically very high in compact body | High, depends on vessel & plumbing |

| Accuracy/stability | Excellent for confining pressure; fewer channels | Excellent if well-tuned; more channels to maintain |

| Pore pressure5 | Usually not measured | Full pore pressure & drainage control |

| Strain measurement | Global; local possible with fixtures | Global + local (axial/radial), extensometers |

| Stress paths | Simple confined compression | CU/CD, constant p′, K₀, cyclic, custom |

| Throughput | Fast screening | Slower setup, richer data |

| Learning curve | Short | Longer; instrumentation discipline |

| Best for | Strength envelopes under pressure6 | Design-grade, research-level characterization |

Which Should You Buy? A Practical Checklist

Buy for your questions, not just your budget. Map decisions to pressure, data depth, and schedule.

If you need speed and strength envelopes—Hoek. If you need effective-stress paths, pore pressure, and stiffness laws—conventional. Many labs benefit from both.

Before I sign a PO, I force a short, honest checklist across program goals7, pressure, instrumentation, people, and lifecycle. If most tests are quick strength screens for quarry control or preliminary tunnel classes, a Hoek cell pays back fast. If most tests feed finite-element models, face-stability studies, or storage injection safety, the conventional rig’s sensor suite is non-negotiable. Consider people: do you have technicians comfortable with pore lines, B-checks, and local strain? Consider lifecycle: spare seals, service access, and calibration plans. And remember hybrids: a small Hoek plus one well-equipped conventional cell gives you speed + depth without blowing the budget. I’ve included a mini decision table and a trial matrix8 you can run with vendor demos—collect the same ramp, hold, and data overlays from both systems and let the plots decide. Templates: trial run script here, SOP bundle here, lifecycle cost sheet here.

Buyer’s quick checklist (tick what matches you)

| Question | If “Yes” → Lean |

|---|---|

| We need many high-pressure strength screens weekly | Hoek |

| We need pore pressure and CU/CD effective paths | Conventional |

| We must run constant p′ / cyclic paths | Conventional |

| We have limited bench space and simple goals | Hoek |

| We can operate two systems (screen + deep dive) | Both |

| We must defend parameters to review boards | Conventional |

Conclusion

Match the tool to the question: Hoek for fast, high-pressure strength; conventional for rich, design-grade rock behavior.

-

Explore this link to understand the Hoek cell’s design and its advantages in rock strength testing. ↩

-

Learn about axial load/displacement to grasp its significance in evaluating rock strength and behavior. ↩

-

Understanding dilation angles is crucial for predicting soil behavior under stress, making this resource invaluable for your research. ↩

-

Exploring design-grade parameters will enhance your knowledge of soil mechanics and improve your engineering designs. ↩

-

Understanding pore pressure is crucial for accurate soil behavior analysis and effective engineering design. ↩

-

Exploring this topic will enhance your knowledge of soil mechanics and its applications in construction. ↩

-

Understanding how to set clear program goals can enhance project success and alignment with objectives. ↩

-

A well-structured trial matrix can help you objectively compare vendor offerings and make informed decisions. ↩