How to Choose the Right Porous Stones for Your Triaxial Test Apparatus

Porous stones1 are crucial components in triaxial testing, directly affecting the accuracy and reliability of your soil test results. Choosing the right porous stones is essential to ensure accurate pore pressure measurements, proper drainage, and long-lasting performance of your triaxial equipment.

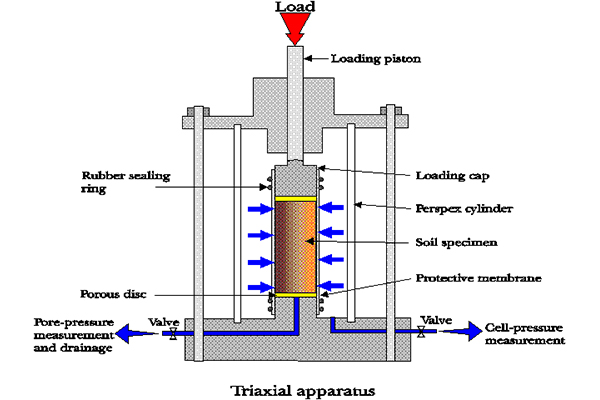

Understanding the Function of Porous Stones in Triaxial Testing

Porous stones1 in triaxial testing serve two main purposes:

- Uniform Drainage: Allowing water to flow in and out of soil samples consistently.

- Accurate Pore Pressure Measurement2: Ensuring pore water pressure readings are accurate and representative of the soil conditions.

Selecting appropriate porous stones helps maintain precise and repeatable triaxial testing results.

[^1] in triaxial test apparatus placeholder](https://latexmembrane.com/wp-content/uploads/2025/07/Latex-Membranes-1-3.jpg)

Key Factors to Consider: Size, Thickness, and Pore Size3

When selecting porous stones, consider these critical factors:

- Diameter: Must match your triaxial cell and soil sample size (common sizes: 35 mm, 50 mm, 70 mm, 100 mm, etc.).

- Thickness: Typically ranges from 5 mm to 10 mm; thicker stones provide greater durability, while thinner ones may enhance sensitivity.

- Pore Size3: Affects drainage rate and pressure accuracy. Standard pore sizes range between 5 µm to 100 µm, depending on soil type.

| Soil Type | Recommended Pore Size3 | Application |

|---|---|---|

| Fine Clay | 5–10 µm | Slow drainage, high accuracy |

| Silt | 10–20 µm | Moderate drainage |

| Sand/Gravel | 20–100 µm | Faster drainage, less clogging |

Material Matters: Ceramic vs. Sintered Metal Porous Stones4

Choosing between ceramic and sintered metal porous stones depends on testing conditions:

-

Ceramic Porous Stones:

- Pros: Excellent chemical resistance, cost-effective, widely available.

- Cons: Fragile, prone to cracking if mishandled.

-

Sintered Metal Porous Stones:

- Pros: Robust, durable, withstands high pressure and repeated use.

- Cons: Slightly higher initial cost, potential for corrosion in aggressive chemical environments.

Evaluate your specific testing needs, sample types, and budget to select the most suitable material.

Maintenance Tips5 to Extend the Lifespan of Porous Stones

Proper maintenance ensures the porous stones perform consistently and last longer:

- Regular Cleaning6: Wash stones gently with distilled water or ultrasonic cleaners after every test to remove soil particles.

- Avoid Harsh Chemicals: Use mild cleaning agents to prevent material degradation or damage.

- Dry Properly: Ensure porous stones are thoroughly dried after cleaning to avoid biological growth or contamination.

- Storage: Store stones in a clean, dry environment to prevent contamination or damage between tests.

Routine care significantly prolongs the lifespan of your porous stones, ensuring accurate, reliable triaxial tests.

Conclusion

Choosing the right porous stones involves carefully considering size, thickness, pore size, and material. With proper selection and regular maintenance, porous stones will provide accurate, reliable performance in your triaxial testing apparatus, enhancing the quality of your soil mechanics research and engineering projects.

-

Explore this link to understand the various types of porous stones and their specific applications in triaxial testing. ↩ ↩

-

This resource will provide insights into techniques and best practices for achieving accurate pore pressure measurements. ↩

-

Learn about the impact of pore size on drainage rates and pressure accuracy in soil testing. ↩ ↩ ↩

-

Discover the pros and cons of each material to make an informed choice for your testing needs. ↩

-

Explore essential maintenance tips to ensure your porous stones remain reliable and effective for triaxial testing. ↩

-

Find effective cleaning methods to maintain the performance and longevity of your porous stones. ↩