Lab Equipment for Sulfur Mortar Capping

Sulfur mortar capping is a widely used method for preparing concrete cylinders for compressive strength testing. To ensure accurate, repeatable results and laboratory safety, the process requires specialized equipment that can handle high temperatures, shape molten material precisely, and protect users from hazardous fumes. This article outlines the essential lab tools and safety gear for effective sulfur capping.

Sulfur Melting Pot: Safe and Uniform Heating

At the heart of sulfur capping is the melting pot1, a specially designed electric or thermostatically controlled unit that safely melts sulfur mortar to the required temperature—typically between 120°C and 150°C (248°F to 302°F).

Key Features:

- Thermostat control to avoid overheating and decomposition

- Double-wall insulation for operator safety

- Removable crucible for easy pouring and cleaning

- Temperature indicator to monitor melting progress

| Specification | Typical Range |

|---|---|

| Capacity | 4 to 20 liters |

| Temperature range | 0 – 200°C |

| Heating time | 30–60 minutes |

Using a dedicated melting pot ensures even heating, prevents sulfur burning (which can release toxic SO₂), and extends the lifespan of the capping material.

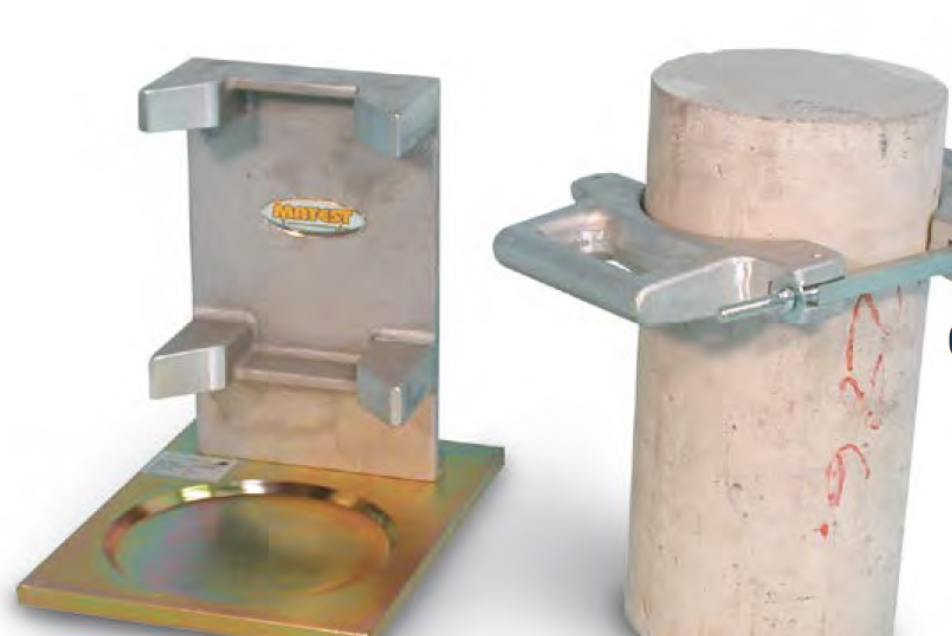

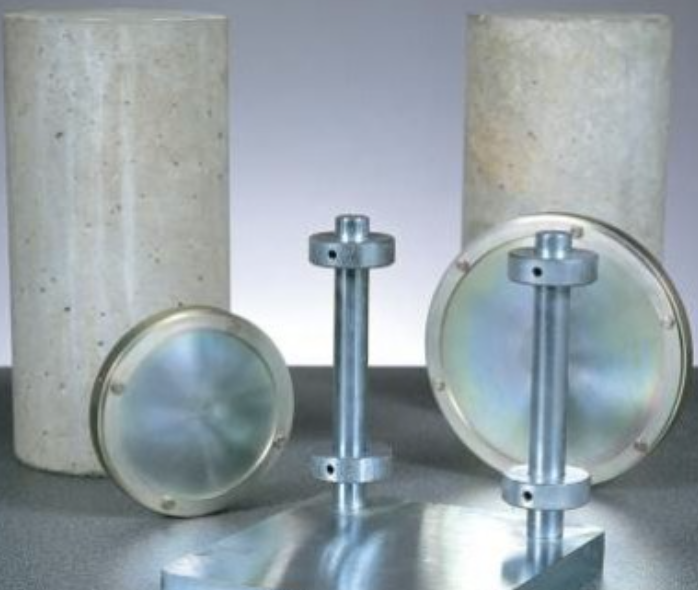

Capping Molds: Shaping Accuracy

Once molten, sulfur mortar must be poured into capping molds2 to create flat, level layers on the ends of concrete cylinders. These molds hold the cylinder upright and guide the cap to a uniform thickness—typically 3–6 mm3.

Types of Molds:

- Steel molds with centralizing rings4 for precise centering

- Adjustable-height molds for various cylinder sizes

- Quick-release base plates for efficient demolding

| Cylinder Size | Mold Diameter | Cap Thickness Range |

|---|---|---|

| 150 × 300 mm | 152 mm | 3–6 mm |

| 100 × 200 mm | 102 mm | 2–4 mm |

Accurate molds contribute to uniform stress distribution during compression testing, reducing variability and improving data reliability.

Ventilation and Fume Extraction Units

Heating sulfur mortar releases irritating and potentially harmful fumes5, especially if the material is overheated. Proper ventilation is essential in any sulfur capping station.

Recommended Solutions:

- Local exhaust ventilation (LEV)6 above the melting pot

- Ducted fume hoods7 or benchtop extraction arms

- Charcoal or HEPA filtration units for enclosed spaces

| Hazard | Control Method |

|---|---|

| Sulfur dioxide fumes | Direct fume capture |

| Dust from filler material | HEPA-filtered air systems |

| Heat exposure | Air circulation + shielding |

Installing fume extraction not only complies with OSHA/ISO safety standards—it ensures a safe and breathable lab environment for technicians.

Protective Tools and PPE: Safety First

Working with molten sulfur requires strict safety protocols8 and personal protective equipment (PPE)9 to avoid burns, inhalation hazards10, and eye injuries.

Essential PPE:

- Heat-resistant gloves

- Face shields or safety goggles

- Long-sleeved flame-retardant lab coats

- Respirators (where ventilation is insufficient)

Recommended Tools:

- Stainless steel pouring ladles

- Non-stick spatulas for leveling caps

- Infrared thermometer for monitoring pot temperature

| Item | Purpose |

|---|---|

| Heat gloves | Protect hands from molten splash |

| Safety goggles | Prevent eye injuries from fumes/spray |

| Ladle + spatula | Controlled pouring and leveling |

| Apron or coat | Shield from thermal splatter |

By combining proper tools with trained handling procedures, labs can achieve efficient sulfur capping with minimal risk.

Conclusion

Sulfur mortar capping remains a reliable and cost-effective technique for preparing concrete specimens—but only when supported by the right lab equipment and safety measures. From precision molds and melting pots to ventilation systems and PPE, every piece of gear plays a role in ensuring that testing accuracy and operator safety go hand in hand.

-

Explore this link to understand the significance and functionality of a melting pot in sulfur capping processes. ↩

-

Explore this link to understand the importance of capping molds in ensuring uniformity and precision in concrete cylinder capping. ↩

-

Learn why maintaining a thickness of 3–6 mm is crucial for the structural integrity and performance of concrete cylinders. ↩

-

Discover how these molds enhance precision and efficiency in the capping process, ensuring better results in construction. ↩

-

Understanding the effects of these fumes is crucial for safety and health in the workplace. Explore this link for detailed insights. ↩

-

Learn how LEV systems can effectively reduce harmful exposure in workplaces, ensuring a safer environment for workers. ↩

-

Discover the advantages of ducted fume hoods for maintaining air quality and protecting health in laboratory settings. ↩

-

Understanding these protocols is crucial for ensuring safety when handling hazardous materials like molten sulfur. ↩

-

Exploring the right PPE can help prevent serious injuries and ensure a safe working environment. ↩

-

Learning about inhalation hazards is vital for implementing effective safety measures in the workplace. ↩