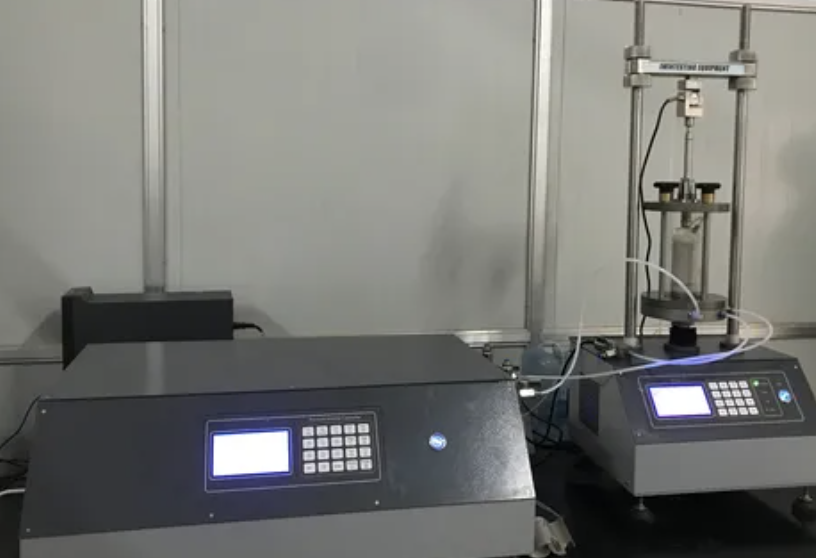

Pneumatic Pressure Controller Buying Guide for Triaxial Soil Testing

Buying the right controller saves weeks of re-tests. I’ve seen quiet, precise pressure turn messy curves into clean, trusted data.

Choose a controller with tight accuracy and low overshoot, solid software integration, verifiable safety compliance, and a lifetime cost you can defend. Prioritize stability, logs, and serviceability.

Let’s walk through accuracy, software, compliance, and total cost—practically, from a lab bench view.

What Accuracy Levels Should You Look for in a Pressure Controller?

If pressure drifts, effective stress lies. Accuracy and stability drive believable CU/CD, permeability, and B-checks.

Target accuracy ≤ ±0.05% FS, resolution ≤ 0.1 kPa, drift ≤ ±0.02% FS/8h, and overshoot that you can cap.

On my first CU program, a “good enough” regulator wasn’t. A tiny overshoot inflated stiffness and faked pore-pressure timing. Since then I score controllers on four simple things: accuracy1, resolution, stability, and control behavior (ramp/hold). Accuracy tells you how close you are to the setpoint; resolution tells you whether tiny steps—say, micro-heads in flexible-wall permeability—are even possible. Stability shows up in boring, flat holds; if your drift is visible to the naked eye, it’s too high. Finally, control behavior matters: fast ramps with low overshoot and adjustable slew rates protect delicate clays. I also check noise under load—some units hum along at idle but wobble when plumbing adds volume. Always ask for setpoint-vs-achieved logs2 from a real cell, not a brochure figure. If a vendor can’t show you flat holds and capped overshoot, keep looking. Bring a short acceptance test: one ramp profile, one long hold, one B-pulse. Save the traces and compare across vendors. You’ll feel the difference the first time your mean effective stress stays put.

Spec cheat sheet (acceptance test template, ramp profile card, hold log sheet)

| Spec | Good | Better | Why it matters |

|---|---|---|---|

| Accuracy (FS) | ±0.10% | ≤ ±0.05% | Honest σ′ and clean k |

| Resolution | 0.2 kPa | ≤ 0.1 kPa | Micro-heads, fine steps |

| Drift (8 h) | ±0.05% FS | ≤ ±0.02% FS | Flat holds, no creep |

| Overshoot | < 2 kPa | < 1 kPa + rate caps | Protects sensitive soils |

How Important Is Software and Automation Compatibility?

Automation turns good intentions into repeatable routines. Software is the difference between “nice hardware” and reliable programs.

Look for open APIs, scriptable profiles, synchronized channels, audit logs, and clean exports that stitch into your DAQ without hacks.

When technicians change, your data shouldn’t. That’s why I buy software first and metal second. A strong controller lets me script saturation ladders, cap rates3 for soft clays, and sync channels (cell/back pressure) for constant-p′ and K₀ paths. I want event logs4 with timestamps for every setpoint and achieved value; six months later, that log will save an argument. Exports matter too: CSV/JSON over a stable socket or file drop so the controller timeline merges with axial load, strain, and pore-pressure in the DAQ. Bonus points if the software supports interlocks (no conflicting valves), pre-run leak checks, and simulated dry runs. I’ve learned to ask three blunt questions: (1) Can I write or edit profiles without vendor help? (2) Can I query live values via API? (3) Can I replay and overlay runs? If any answer is “no,” I keep walking. Integration shouldn’t be a weekend science project; it should be two URLs and a key. And yes—look for user roles so juniors can run profiles while seniors edit them. You’ll sleep better.

Integration checklist (API quick test, profile library starter, log overlay tool)

| Capability | Must-have | Nice-to-have |

|---|---|---|

| Scripted ramps/holds | ✅ | |

| Channel sync (cell/back) | ✅ | |

| API (read/write) | ✅ | GraphQL/REST both |

| Audit logs (immutable) | ✅ | Signed hashes |

| Exports (CSV/JSON) | ✅ | Direct DAQ binding |

| User roles | ✅ | SSO/LDAP |

What Compliance and Safety Standards Should Be Considered?

Compliance isn’t paperwork; it’s predictability and insurance. Safety keeps people—and specimens—alive.

Check CE/UKCA, EMC and electrical safety (e.g., IEC/EN 61010), over-pressure protection, relief valves, and pressure-rated components with traceable calibration.

I’ve seen beautiful hardware with sloppy labeling and missing relief hardware. That’s a no. For labs working under ISO-style QA, I verify CE/UKCA5, EMC immunity/emissions, and electrical safety declarations (e.g., IEC/EN 61010-1) — plus a declaration of conformity that actually lists the standards. Pressure lines should have rated hoses/fittings, clearly marked max working pressure, and a mechanical relief upstream of the controller. For some jurisdictions and ranges, you may touch the Pressure Equipment6 rules; ask the vendor to state applicability in writing. Calibration should come with traceable certificates and interval guidance; I budget annual cal and keep a spare transducer to limit downtime. For environmental policy and procurement, many teams also ask for RoHS/REACH statements. Finally, I want emergency stop behavior documented: what exactly happens to cell/back pressure on E-stop or power loss? A safe default (vent to safe state or hold, depending on test stage) should be selectable and logged. Put all of this into a one-page incoming inspection sheet; if a controller fails two boxes, it doesn’t enter the lab.

Compliance pack (incoming inspection sheet, relief valve sizing note, calibration schedule)

| Area | What to verify | Why it matters |

|---|---|---|

| Electrical safety | IEC/EN 61010-1 report | Lab approval & insurance |

| EMC | Immunity/emissions test | Noise and legality |

| Pressure safety | Relief, rated hoses | People and rigs safe |

| Calibration | Traceable certs | Data defensibility |

| Documentation | DoC + labels | Audit readiness |

How to Balance Cost, Durability, and Maintenance?

Lowest price can be the most expensive choice. Think lifetime, not invoice.

Model total cost: purchase + spares + calibration + downtime. Favor robust valves, cleanable filters, swappable sensors, and responsive support.

I’ve blown more budget on downtime than on list prices. So I price controllers by lifetime, not day one. First, ask for a spares list7 and lead times: valves, seals, sensors, filters. If a $30 seal stops a $30k program for two weeks, that’s a false economy. Second, check service access—can your tech swap a transducer with a hex key, or is it a factory return? Third, confirm calibration intervals and whether the vendor supports field calibration. I also look at mean time between failures8 (even if informal) and the support clock: do you get responses in hours or days? On durability, prefer metal manifolds, protected electronics, and moisture/particulate filtration—air quality kills pneumatics. Add a cheap air dryer and coalescing filter to your quote; you’ll thank me later. Finally, build a simple cost model that includes re-test risk. If Controller A saves two retests a month, it probably pays for itself.

TCO tools (lifetime cost calculator, spares checklist, air quality guide)

| Cost element | Year 1 | Year 2 | Year 3 | Notes |

|---|---|---|---|---|

| Purchase | $$ | — | — | |

| Calibration | $ | $ | $ | Field vs. factory |

| Spares | $$ | $ | $ | Valves/seals/sensors |

| Downtime | ? | ? | ? | Value of re-tests avoided |

| Total (est.) | Use your rates |

A quick story: we picked the “cheaper” unit once. Six months later, a clogged micro-filter took us offline during a tunnel program. The premium unit, with front-panel filter access and spare kit, would’ve kept the schedule intact. Lesson learned.

Conclusion

Buy for quiet pressure, clean logs, and fast service—your triaxial data (and deadlines) will thank you.

-

Understanding accuracy in control systems is crucial for achieving precise setpoints and optimal performance. ↩

-

Analyzing these logs helps ensure your system meets performance expectations and identifies areas for improvement. ↩

-

This resource will provide insights into cap rates and their significance in geotechnical engineering. ↩

-

Explore this link to understand how event logs can enhance data integrity and support decision-making. ↩

-

Understanding CE/UKCA certification is crucial for compliance and safety in lab environments. ↩

-

Exploring Pressure Equipment regulations ensures safety and compliance in lab operations. ↩

-

Understanding a spares list can help you minimize downtime and manage costs effectively. ↩

-

Exploring this concept can enhance your understanding of equipment reliability and maintenance planning. ↩