Ever had those moments in the lab where your test results felt… unreliable? I’ve been there too, especially with soil triaxial tests.

Neoprene membranes help ensure accurate soil test results by isolating samples and maintaining consistent conditions during triaxial tests.

And trust me, switching to neoprene was a game-changer.

What Is Neoprene Membrane and Its Purpose?

Before diving deeper, let’s clarify the basics.

Neoprene membranes are flexible, synthetic rubber sleeves used in soil testing to isolate samples and prevent moisture exchange during triaxial tests.

I remember the first time I handled neoprene membranes1—honestly, I underestimated their value. They felt simple, just stretchy rubber sleeves. But the magic became clear once I started using them regularly in our lab tests.

These membranes wrap tightly around soil samples, creating a perfect barrier. Imagine wearing a waterproof glove while washing dishes—it keeps your hands dry no matter how soaked everything else gets. Similarly, neoprene membranes1 keep soil samples exactly as intended, preventing moisture from escaping or external contaminants from sneaking in.

Why does this matter? Because accurate triaxial testing2 hinges entirely on controlled conditions3. Even slight moisture fluctuations can skew your test results dramatically. That’s why choosing neoprene membranes1—flexible, durable, and reliably non-porous—made a significant difference for me.

In short, neoprene ensures consistency, boosting confidence in every test result we produce.

What’s the Role of Neoprene Membranes in Triaxial Test Setup?

Now, let’s look at their critical role in the test itself.

Neoprene membranes create an airtight, watertight seal around soil samples, ensuring consistent pressure and moisture conditions during triaxial tests.

When I started in this industry, I learned quickly that stability matters. Let me explain:

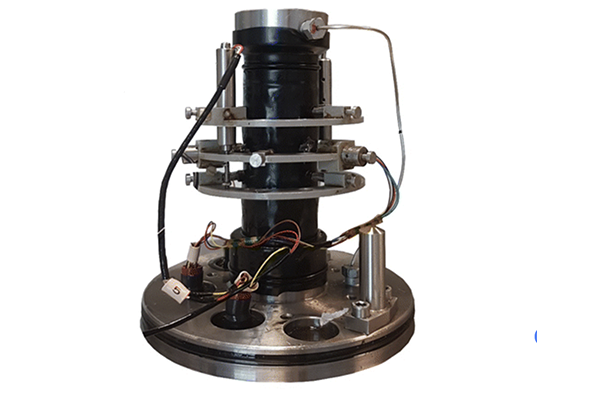

Triaxial tests4 measure how soil behaves under pressure5 from different angles. You place a soil sample inside the testing chamber, and a neoprene membrane1 snugly wraps around it, sealing it completely. Then you apply pressure and see how the sample responds.

The neoprene membrane1 is pivotal here. It maintains constant confining pressure and prevents contamination. Imagine blowing up a balloon to a specific size and tying it off—keeping the air inside at a steady pressure. That’s what the membrane does for soil samples.

Importance of Accurate Seals

If the seal isn’t tight, water or air could leak. Even tiny leaks ruin your data. I once had a frustrating experience when an inferior membrane failed mid-test. The results were off, we wasted days recalibrating, and I swore never again to skimp on quality.

What Are the Key Benefits of Using Neoprene in Soil Testing?

Let’s talk specifics—why exactly neoprene?

Neoprene membranes offer flexibility, durability, chemical resistance, and reliable sealing, essential for accurate soil triaxial tests.

For me, the best part of neoprene membranes isn’t just their sealing capability; it’s their resilience. Testing environments can be harsh—temperature swings, chemical exposures, rough handling. Neoprene handles all of that gracefully.

Here’s why I prefer neoprene:

| Benefit | Explanation |

|---|---|

| Flexibility | Easily adapts to soil samples without tearing. |

| Durability | Withstands multiple uses without degradation. |

| Chemical Resistance | Stays intact even when exposed to aggressive soil conditions. |

| Reliable Seal | Ensures precise test conditions and accurate results. |

In fact, durability6 alone has saved me significant expenses over the years. While cheaper alternatives break or degrade quickly, neoprene membranes keep performing test after test.

I’ve even heard feedback from a client at Globalgilson, who praised our neoprene membranes for their robustness7. He runs tests constantly and needed something reliable. Since switching to neoprene, he’s seen fewer disruptions and more consistent outcomes. That speaks volumes to me.

How Do You Choose the Right Neoprene Membrane?

Picking the perfect membrane involves a bit more than just grabbing what’s cheapest.

Choose neoprene membranes based on thickness, diameter compatibility, chemical resistance, and overall durability to ensure accurate and consistent soil testing results.

When I first started purchasing membranes, honestly, I overlooked some key aspects. Thickness matters a lot—too thin, they break easily; too thick, they become unwieldy. Typically, membranes around 0.3 to 0.8mm thickness work best.

Here’s a quick guide I use myself:

- Thickness: 0.3-0.8mm ideal for most applications.

- Diameter Compatibility: Match membrane size precisely with your test equipment.

- Chemical Resistance: Consider soil chemistry; neoprene’s chemical stability is excellent, but double-check for extreme conditions.

- Durability: Ask for lab test reports or case studies confirming long-term performance.

Choosing membranes carefully saves headaches down the line. I learned the hard way after dealing with a batch of mismatched membranes—it slowed testing and led to poor data quality. Ever since, I always double-check compatibility.

Also, it’s helpful to build a good relationship with a reliable supplier. At How-dy, our membranes are tested rigorously, ensuring they meet the highest standards. It’s peace of mind for me, knowing our clients receive consistent quality.

Conclusion

Neoprene membranes are essential for accurate, consistent, and reliable triaxial soil testing—invest wisely and see results improve immediately.

-

Explore this link to understand the versatile applications of neoprene membranes in lab settings, enhancing your knowledge on their importance. ↩ ↩ ↩ ↩ ↩

-

Discover the significance of triaxial testing in soil mechanics, which is crucial for accurate engineering assessments and project planning. ↩

-

Learn about the impact of controlled conditions on test results, ensuring reliability and accuracy in scientific experiments. ↩

-

Understanding Triaxial tests is crucial for grasping soil behavior under pressure, which is essential for civil engineering and construction projects. ↩

-

Learning about soil behavior under pressure is vital for effective foundation design and stability analysis in engineering projects. ↩

-

Learn about the importance of durability in material selection and how it can save costs in the long run. ↩

-

Discover the characteristics that define robustness in materials and why it matters for performance and reliability. ↩