Top 5 Lab Applications That Rely on Butyl Rubber Membranes

In precision geotechnical and environmental laboratories, membrane materials can make or break a test. While latex has long dominated standard procedures, butyl rubber membranes are rising as the preferred choice for high-integrity applications, thanks to their superior impermeability, chemical resistance, and dimensional stability. Here are five lab tests where butyl rubber isn’t just useful—it’s essential.

Triaxial Shear Testing for Soil Stability

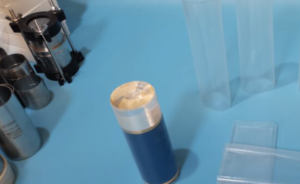

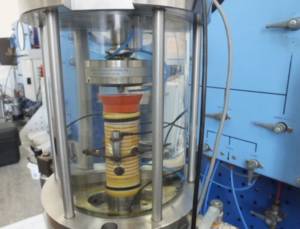

In triaxial testing, membranes isolate the soil specimen from the confining fluid, allowing accurate measurement of shear strength and stress-strain behavior under pressure.

Why Butyl Rubber Excels:

- Low deformation under stress1, preserving specimen geometry

- High rupture resistance2, even under large confining pressures

- Excellent sealing to maintain effective stress and pore pressure

| Параметр | Importance in Triaxial Testing |

|---|---|

| Membrane stretch resistance | Prevents distortion |

| Airtight seal | Maintains valid pressure data |

| Chemical inertness | Withstands soil pore fluids |

In CU (Consolidated Undrained) and CD (Consolidated Drained) tests, butyl membranes reduce variability and improve the reliability of long-duration measurements3.

Permeability Testing of Soil Samples

Soil permeability tests are highly sensitive to membrane leakage, making butyl’s low permeability a significant advantage.

Benefits of Using Butyl:

- Virtually zero water vapor transmission4

- Doesn’t affect flow rate calculations

- Maintains seal integrity over multi-day test durations

| Тип теста | Risk Without Proper Membrane |

|---|---|

| Constant Head Test | Leaks distort hydraulic gradient |

| Falling Head Test | Air transfer skews results |

| Flexible Wall Permeability | Essential for confining pressure setup |

If you’re measuring saturated hydraulic conductivity5, butyl membranes eliminate a major source of error6.

Barrier Materials in Gas/Vapor Containment Studies

Whether it’s landfill barrier research or indoor air quality modeling, precise gas containment is non-negotiable. Butyl’s exceptional impermeability to gas makes it the go-to material.

Why It Works:

- Dense molecular structure blocks methane, radon, and VOCs

- Remains stable under chemical and pressure exposure

- Prevents cross-contamination in multi-layered test chambers

| Contaminant Type | Membrane Requirement |

|---|---|

| Soil vapor | High gas-tightness |

| Industrial solvents | Chemical resistance essential |

| VOCs | Inert, low-absorption material |

For research on vapor intrusion or sealant evaluation, butyl rubber is a material you can trust.

Sample Isolation in Contaminant Leaching Tests

Leaching tests require complete isolation of the soil or waste sample, especially when analyzing heavy metals, nitrates, or hydrocarbons in solution.

Butyl Rubber’s Role:

- Provides chemical stability7 in contact with acids, alkalis, and solvents

- Prevents dilution or cross-leaching8 from external fluid exposure

- Maintains mechanical shape, avoiding edge effects or test distortion

| Application Area | Common Testing Objective |

|---|---|

| Landfill design | Predict leachate migration |

| Environmental audits | Assess site contamination potential |

| Regulatory testing | Verify compliance with leaching limits |

Where results feed into regulatory compliance or cleanup planning9, the membrane must not be the weak link—and butyl ensures it isn’t.

—

Заключение

From soil mechanics to environmental risk analysis, butyl rubber membranes offer the consistency, impermeability, and chemical resilience that modern labs demand. If your testing requires precision, durability, and zero compromise, these five applications prove: butyl is not just an option—it’s the standard.

-

Understanding low deformation under stress can enhance material selection for engineering applications, ensuring durability and performance. ↩

-

Exploring high rupture resistance helps in selecting materials that can withstand extreme conditions, crucial for safety and reliability. ↩

-

Learning about the reliability of long-duration measurements can improve testing accuracy and data integrity in engineering projects. ↩

-

Understanding zero water vapor transmission can help you choose the right membrane for your projects, ensuring efficiency and accuracy. ↩

-

Exploring this topic will deepen your knowledge of soil permeability and its significance in environmental engineering. ↩

-

Learn how butyl membranes can enhance the accuracy of your hydraulic tests, leading to better project outcomes. ↩

-

Understanding chemical stability is crucial for ensuring material performance in various environments, especially in construction and environmental applications. ↩

-

Exploring this topic reveals how effective barriers can protect ecosystems and maintain site integrity, essential for environmental management. ↩

-

This resource can provide insights into effective strategies for meeting regulations and ensuring successful cleanup efforts, vital for project success. ↩