Top Considerations When Buying a Lab Sieve Shaker: From Budget to Standards

Buying a lab sieve shaker might seem straightforward—until you realize how many types, features, and standards are involved. Whether you’re in geotechnical testing, pharmaceutical QC, or materials research, choosing the wrong shaker can lead to inaccurate results, wasted time, and expensive replacements. Here’s a clear guide to help you make a smart, long-term investment.

Define Your Application and Particle Size Range

Before anything else, get specific about what materials you’re testing and how fine the separation needs to be. The type of motion, sieve compatibility, and frequency control you need all depend on this.

Ask Yourself:

- What material are you analyzing? Soil, cement, powders, food, chemicals?

- What’s the size range? (e.g. 75 μm to 20 mm)

- Do you need dry sieving, wet sieving, or both?

| Application | Recommended Shaker Type |

|---|---|

| Soil and aggregates | Mechanical or rotary sieve shaker1 |

| Fine powders (<100 µm) | Electromagnetic or sonic shaker2 |

| Pharmaceuticals | Air jet or sonic sieve shaker3 |

Choosing based on your actual testing needs ensures accuracy and avoids overpaying for unnecessary features.

Evaluate Compliance with Industry Standards

Accuracy and traceability often depend on your ability to meet international testing standards. Not all sieve shakers are certified or designed to operate within required parameters.

Common Standards:

- ASTM C136 / D6913 – Particle size analysis for aggregates and soil

- ASTM E11 / ISO 3310 – Wire mesh sieve specifications

- USP / FDA – For pharmaceutical sieving processes

Ensure the sieve shaker can:

- Maintain standard sieve sizes and stack height

- Provide timed and consistent motion

- Support calibration and traceable validation4

| If You're In… | Check Compliance With… |

|---|---|

| Construction labs | ASTM and AASHTO |

| Environmental research | ISO/IEC standards |

| Pharma and food | FDA, GMP, and USP guidelines |

Choosing a shaker aligned with your compliance requirements helps avoid audit issues and retesting costs5 later on.

Consider Budget, Maintenance, and Lifecycle Cost

The purchase price is just one part of the cost equation. A cheaper shaker might cost more over time if it requires frequent repairs, lacks parts support, or isn’t energy efficient.

Key Cost Factors:

- Initial cost: Electromagnetic shakers6 are often pricier than mechanical models.

- Maintenance7: Does it require regular calibration or motor service?

- Replacement parts8: Are they easily available and affordable?

- Warranty: What’s covered and for how long?

| Budget Tier | Shaker Type | Best For |

|---|---|---|

| Low ($1,000–2,000) | Manual/mechanical | Basic soil/aggregate testing |

| Mid ($2,000–4,000) | Electromagnetic/rotary | Research labs, QC applications |

| High ($5,000–10,000+) | Sonic/automated air jet | Pharma, micro-particle research |

Think beyond the upfront price—investing smart upfront often means fewer headaches down the line.

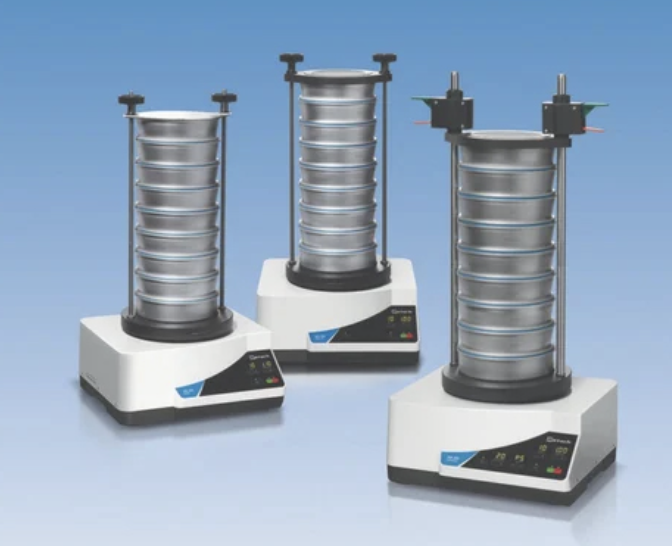

Check Capacity, Automation, and Noise Levels

Lab environments demand user-friendly, space-efficient, and low-noise solutions—especially if testing happens frequently.

Questions to Ask:

- How many sieves can it hold? (Standard is 8–10 for 8" sieves)

- Is there a built-in timer and programmable cycle?

- What’s the noise rating in decibels?

- Is it easy to stack and secure sieves?

| Feature | Why It Matters |

|---|---|

| Programmable timer | Consistent test results, even for new staff |

| Large stack capacity | Increases productivity and batch throughput |

| Quiet operation (<70 dB) | Better for shared or enclosed lab spaces |

| Compact footprint | Saves benchtop or mobile cart space |

Modern sieve shakers are available with touchscreen interfaces, USB data export, and noise-dampening designs. These might add cost—but greatly improve efficiency and user comfort.

Conclusion

Choosing the right sieve shaker is about more than specs—it’s about matching your lab’s workflow, budget, and compliance needs. Take time to assess the materials you work with, the standards you must meet, and the long-term costs. When chosen wisely, a sieve shaker isn’t just a tool—it’s a trusted lab companion that delivers speed, accuracy, and confidence in every test.

-

Explore this link to understand the applications and benefits of using mechanical or rotary sieve shakers in various industries. ↩

-

Discover how electromagnetic or sonic shakers can enhance the efficiency of fine powder analysis in your lab. ↩

-

Learn about the advantages of air jet or sonic sieve shakers in pharmaceutical testing and their unique features. ↩

-

Exploring calibration methods can enhance the reliability of your lab results and ensure compliance with regulatory standards. ↩

-

Learning about common audit issues can help you prepare better and avoid unnecessary retesting costs in your lab operations. ↩

-

Explore the benefits of Electromagnetic shakers to understand why they might be worth the investment despite higher initial costs. ↩

-

Learn about the maintenance needs of Electromagnetic shakers to ensure they fit your operational capabilities and budget. ↩

-

Discover the availability and cost of replacement parts for Electromagnetic shakers to avoid unexpected expenses later. ↩