What Equipment Is Needed for a Proctor Compaction Test?

The Proctor Compaction Test is essential in determining the maximum dry density and optimal moisture content of soils for stable construction projects. Choosing the correct equipment ensures accurate and reliable results. Let’s explore the key tools required for this crucial test.

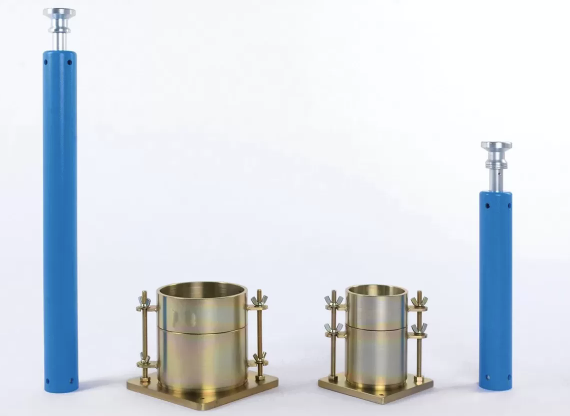

What Is the Standard Proctor Mold and Rammer?

The Proctor mold1 and rammer are the core components of the test. They standardize compaction force2 and sample volume.

- Proctor Mold: Usually cylindrical, commonly 4 inches (101.6 mm) in diameter and 4.584 inches (116.4 mm) high, providing a consistent sample volume.

- Compaction Rammer3: Typically weighs 5.5 lbs (2.5 kg), dropped from a height of 12 inches (305 mm) to compact soil uniformly.

These standards ensure consistency, repeatability, and comparability across tests.

Why Is a Drying Oven and Moisture Can Crucial?

Accurately determining soil moisture content4 requires precise drying.

- Drying Oven5: Maintains a consistent temperature (typically around 110°C) to remove soil moisture completely without altering soil properties.

- Moisture Cans: Small, airtight containers used to measure the precise water content of soil samples.

Together, these tools help determine exact moisture content, critical for accurate density calculations.

What Kind of Balance Is Used for the Test?

An accurate balance scale is essential for weighing samples.

- Precision: A scale accurate to at least 1 gram (0.01 lb) ensures reliability in moisture and density measurements.

- Capacity: Typically, balances used have a capacity of around 10 kg, suitable for handling soil samples and molds.

High-accuracy balances prevent measurement errors, ensuring valid and reproducible test results.

Are Any Additional Tools Required?

Besides primary equipment, additional tools include:

- Sieves (No. 4 or 4.75 mm)6: To standardize soil particle size.

- Mixing tools7: Containers and spatulas to evenly mix water into the soil.

- Straightedge and scoops: To level soil surfaces within the mold.

- Plastic bags or containers8: To store samples and maintain moisture levels before testing.

These supplementary tools facilitate smooth testing procedures, enhancing accuracy and efficiency.

Заключение

The Proctor Compaction Test requires specific, standardized equipment to ensure accurate results. Using quality molds, rammers, drying ovens, precise balances, and supplementary tools guarantees reliable data for robust construction and geotechnical decisions.

-

Understanding the Proctor mold’s role can enhance your knowledge of soil compaction tests and their importance in construction. ↩

-

Learning about the standardization of compaction force can help you grasp its significance in achieving reliable test results. ↩

-

Exploring the function of a compaction rammer will provide insights into effective soil compaction techniques and their applications. ↩

-

Discover the significance of accurate soil moisture content in density calculations, impacting agricultural practices and soil management. ↩

-

Explore how a drying oven ensures accurate soil moisture content measurement, crucial for various agricultural and environmental applications. ↩

-

Understanding the role of sieves can enhance your knowledge of soil particle size standardization, crucial for accurate testing. ↩

-

Exploring the importance of mixing tools can help you grasp their impact on achieving uniform soil consistency for better results. ↩

-

Learn about the significance of proper sample storage to maintain moisture levels, which is vital for reliable soil testing outcomes. ↩