Why De-airing Devices Are Critical for Reliable Triaxial Test Results

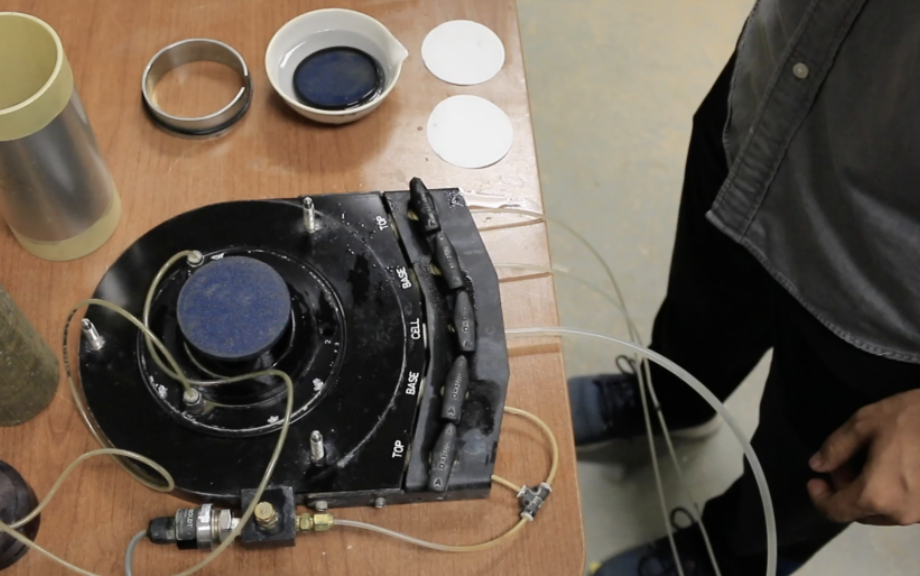

When I want trustworthy triaxial data, I start by removing air from the system. A tiny bubble can distort pore pressure, change stiffness, and waste a full day of testing. That’s why de-airing devices are not “nice to have”—they’re essential.

What Happens If Air Remains in the System?

Air changes everything. It is compressible; water (for our purposes) is not. Even a small amount of air in the tubing, porous stones, or specimen can cause:

- Low B-values1 (e.g., Mild warming (≈ 25–35 °C) speeds degassing; keep temperatures modest to avoid affecting seals or specimen state.

Why Are De-aired Fluids Needed for Saturation?

Saturation is about replacing air with water inside the specimen and the drainage system. If the supply water carries dissolved gas—or your lines hold bubbles—you fight a losing battle.

- Higher achievable B-values2: De-aired water + back pressure makes B ≥ 0.95 realistic and repeatable.

- Stable pore pressure response3: No artificial damping or “springiness.”

- Cleaner effective stress path: Less noise in CU/UU tests and better control in CD tests.

- Consistent cyclic behavior: Reduced phase lag in cyclic triaxial and simple shear analogs.

Think of de-aired water as the “silent partner” that lets your pore pressure transducer tell the truth.

Best Practices for Using De-airing Devices

Adopt a simple, repeatable routine. Here’s a field-tested checklist I use:

Setup & Integration

- Use low-permeability tubing (PTFE, PFA, stainless) from de-airing unit to cell—short runs, minimal fittings.

- Install a micro-filter (≈0.45 µm) downstream of the de-airing device to catch particulates that seed bubbles.

- Pre-evacuate porous stones, lines, and top cap channels before flooding with de-aired water.

Operating Targets

- Run chamber/contactor until no visible bubbles and DO meets target.

- Maintain vacuum at −70 to −85 kPa (gauge); verify with an independent gauge.

- If using back pressure saturation, step up cell/back pressures gradually to avoid membrane collapse.

Handling & Timing

- Flood from bottom up4 to push air out, not trap it.

- Avoid pauses with open lines; air re-enters quickly. Keep the system closed.

- Use freshly de-aired water5 for each batch of specimens; don’t rely on yesterday’s tank.

QA/QC & Documentation

- Record vacuum level, DO (if available), time, and temperature in the log.

- Confirm saturation with a B-check6 (aim ≥ 0.95, many labs push to ≥ 0.97 for soft clays).

- Under ISO/IEC 170257 workflows, keep maintenance logs (membrane changes, filter swaps, leak tests).

Troubleshooting Quick Table

| Симптом | Вероятная причина | Fast Fix |

|---|---|---|

| B-value stalls at 0.85–0.90 | Air in lines / high DO water | Re-degass, re-evacuate lines, replace micro-filter |

| Pore pressure “lags” in loading | Micro-bubbles in porous stones | Pre-evacuate stones, flood bottom-up, increase BP |

| Bubbles reappear after setup | Permeable tubing / leaking fitting | Swap to PTFE/PFA, re-seal, shorten runs |

| Noisy transducer signal | Entrained gas near sensor | Re-bleed transducer tee, purge with de-aired water |

Заключение

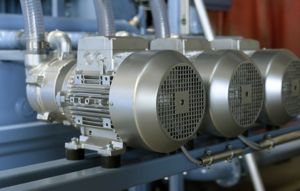

Reliable triaxial data starts long before the first load increment. De-airing devices protect your test from hidden compressibility, enabling high B-values, stable pore pressures, and repeatable effective stress paths. Choose an appropriate device (chamber, inline membrane, or recirculating), hit sensible vacuum/DO targets, and follow a tight operating routine. Your specimens—and your results—will show the difference.

-

Understanding Low B-values is crucial for accurate soil testing and analysis, ensuring reliable engineering decisions. ↩

-

Understanding the advantages of higher B-values can enhance your testing accuracy and reliability. ↩

-

Exploring methods for stable pore pressure response can improve your testing outcomes and data integrity. ↩

-

Explore this link to understand effective flooding techniques that enhance air removal in water systems. ↩

-

Learn why using freshly de-aired water is crucial for maintaining specimen integrity and preventing contamination. ↩

-

Understanding B-checks is crucial for ensuring accurate saturation levels in soft clays, enhancing your lab’s reliability. ↩

-

Exploring ISO/IEC 17025 will help you grasp essential standards for laboratory quality and competence, ensuring compliance and excellence. ↩