Test Sieve Accuracy: Verification, Calibration, & Performance

Test sieves might look simple—but their precision plays a critical role in granular material testing across industries like construction, pharmaceuticals, agriculture, and geotechnics. Whether you’re classifying soil particles or controlling powder flow in a production line, sieve accuracy determines the reliability of your results. Let’s unpack what that really means and how you can maintain confidence in your sieving process.

Understanding Sieve Accuracy and Its Importance

Sieve accuracy refers to how closely the mesh openings match their designated nominal sizes, such as those defined by ASTM E11 or ISO 3310. Even tiny deviations in mesh spacing can skew your particle size analysis1, leading to bad data and potentially costly decisions.

Why It Matters:

- Quality control depends on consistent gradation.

- Repeatability between labs relies on standardized sieve performance.

- Specification compliance ensures products meet regulatory or contractual requirements.

| Accuracy Concern | Potential Impact |

|---|---|

| Larger-than-specified openings | Finer particles pass through, skewing results |

| Worn or deformed mesh | Causes uneven separation, lower reliability |

| Unverified sieve stacks | Fails audits or inter-lab comparisons |

Without accurate sieves, even the best lab setup can’t guarantee trustworthy data.

Verification vs. Calibration: What’s the Difference?

While both ensure sieve performance, verification2 and calibration3 serve different purposes—and understanding the distinction is key for proper quality management.

Definitions:

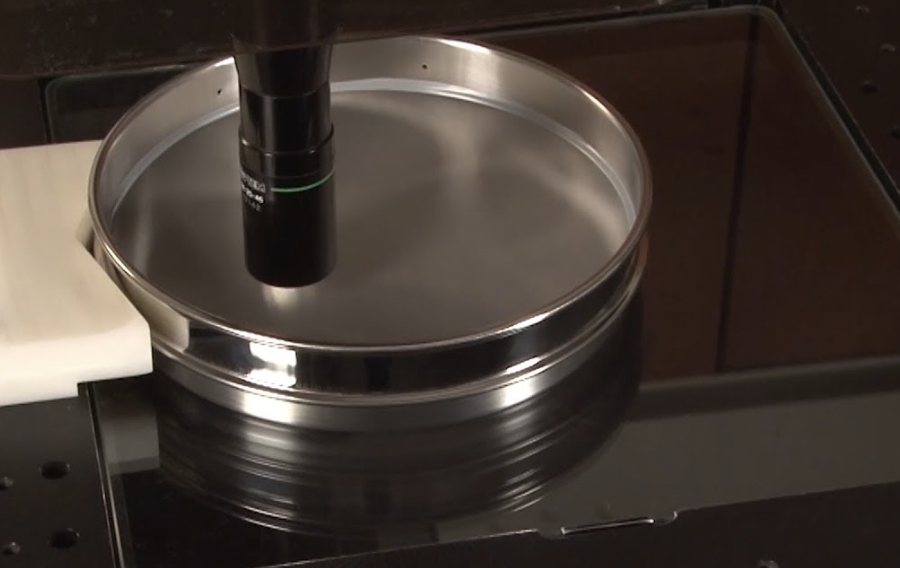

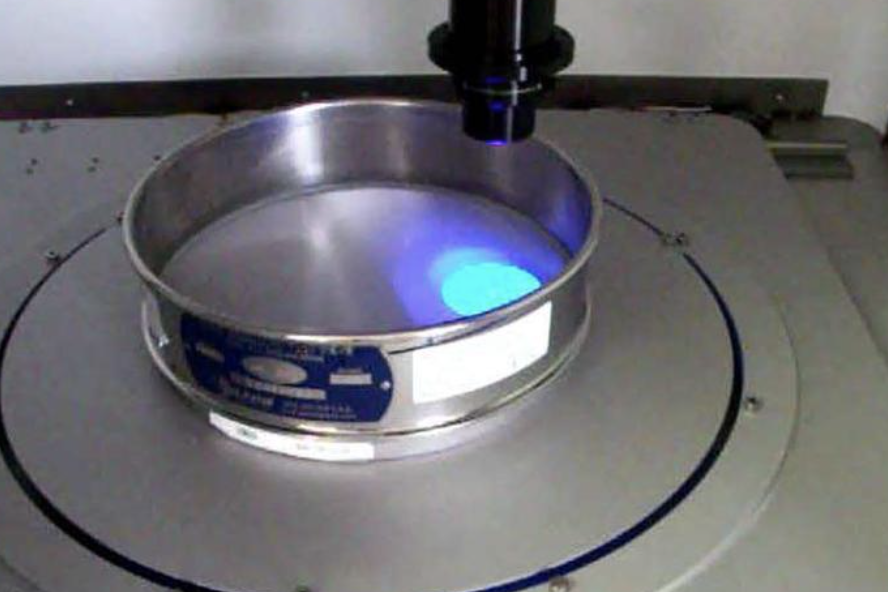

- Verification: A periodic check confirming that sieve openings4 fall within acceptable tolerances. Usually done by sampling mesh openings with optical tools.

- Calibration: A more in-depth process where every opening or section of the mesh is measured and recorded. Often used for inspection-grade or master sieves.

| Aspect | Verification | Calibration |

|---|---|---|

| Purpose | Confirms sieve meets tolerance specs | Maps actual dimensions of the mesh |

| Frequency | Every 6–12 months | As needed, usually less frequent |

| Detail Level | Random sampling | Full mesh mapping |

| Cost | Lower | Higher |

Most labs will routinely verify working sieves and reserve calibration for reference sieves used in compliance testing.

Key Performance Factors in Sieving Efficiency

Sieve accuracy is only one part of the picture. Performance during testing5 can be affected by a number of operational factors—even when the sieve is within spec.

Key Factors:

- Sample load6: Overloading can reduce separation efficiency and cause mesh damage.

- Sieving time: Inadequate or excessive time changes retention behavior.

- Shaker amplitude and frequency7: Needs to be consistent and appropriate for the material.

- Clogging and blinding: Fine or sticky particles can reduce open area and skew results.

| Factor | Effect on Sieving |

|---|---|

| Overloaded sieves | Poor separation, mesh deformation |

| Improper cleaning | Residue buildup changes effective aperture size |

| Vibratory imbalance | Uneven distribution across sieve surface |

For precise results, equipment settings must be controlled with the same attention as the mesh itself.

Best Practices for Reliable Sieve Maintenance

To maintain both accuracy and performance, sieve maintenance should be built into your regular lab routines8. Clean, inspect, and verify often—and document everything.

Best Practices:

- Inspect visually before use9: Look for broken wires, dented frames, or clogged mesh.

- Clean gently: Use soft brushes or ultrasonic baths—avoid abrasives.

- Rotate sieves in high-use environments: Distribute wear evenly across your stock.

- Label and track calibration/verification status10: Use QR codes or log sheets.

| Task | Recommended Frequency |

|---|---|

| Visual inspection | Before each use |

| Gentle cleaning | After each test |

| Verification (ASTM/ISO) | Every 6 to 12 months |

| Full calibration | As required or for master sieves |

A good maintenance plan protects your investment in equipment and upholds the integrity of your data.

Conclusion

Accurate test sieves are the unsung heroes of material testing. From routine verification to performance monitoring and calibration, proper care ensures every test result is valid, traceable, and trusted. By following best practices and understanding how accuracy ties into broader system performance, labs can reduce error, meet compliance, and produce data that decision-makers can count on.

-

Exploring the impact of particle size analysis can help you understand its significance in quality control and regulatory compliance. ↩

-

Understanding verification is crucial for maintaining quality in sieve performance. Explore this link to learn more about its importance. ↩

-

Calibration is essential for precise measurements in sieve testing. Discover more about its role and significance in quality management. ↩

-

Sieve openings are critical for ensuring accurate results in testing. Learn more about their significance in quality management practices. ↩

-

Understanding the factors influencing sieve performance can help optimize testing processes and improve results. ↩

-

Exploring the impact of sample load on sieve performance can lead to better operational practices and enhanced efficiency. ↩

-

Learning about the significance of shaker amplitude and frequency can help ensure effective sieving and accurate results. ↩

-

Explore this resource to learn how to effectively incorporate maintenance into your lab routines for optimal performance. ↩

-

Understanding the significance of visual inspections can enhance your lab’s safety and efficiency. ↩

-

Discover methods to ensure your equipment is always calibrated and compliant, enhancing reliability in your lab work. ↩