The durability of many products depends on subtle factors, and triaxial latex membranes are among the silent heroes ensuring reliable performance.

Triaxial latex membranes help maintain stable, controlled environments during tests, preventing leaks and ensuring accurate data for improved product durability.

They’re more impactful than most people realize.

What is the effect of flexible membrane in large scale triaxial test dem simulations?

Flexible membranes support uniform stress distribution, allowing realistic data in large-scale triaxial test simulations.

A flexible membrane minimizes boundary errors, improving simulation accuracy and providing essential insights into material behavior.

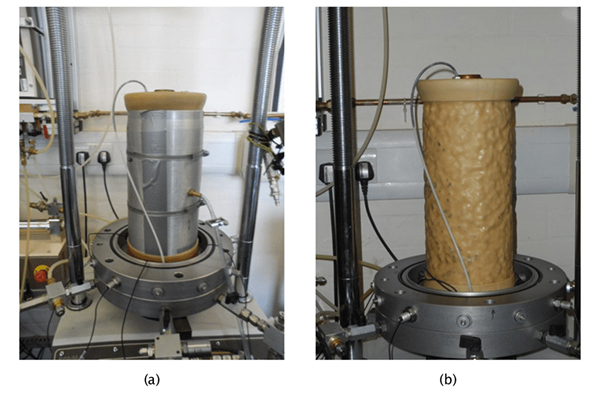

I remember my first time witnessing a large-scale triaxial test simulation1—it felt like stepping into a high-stakes science fair. The soil sample was enormous, and the entire setup looked like a miniature concert stage, complete with pressure gauges and blinking sensors. As I observed the process, one detail stood out: the flexible latex membrane2 hugging the soil sample. You’d think a simple membrane wouldn’t matter much, but let me tell you, it does. By conforming closely to the sample, the membrane reduces friction and boundary issues, ensuring every part of the sample experiences stress the way it would underground.

In large-scale simulations, precision is key. If the membrane can’t handle the load or if it wrinkles too much, the results can be misleading. That’s where Howdy’s membranes often come into play—our manufacturing approach focuses on consistent thickness and elasticity, allowing for smooth adaptation to varied sample shapes. The difference might seem small, but a single wrinkle could throw off measurement results, especially when analyzing complex materials like crushed aggregates or partially saturated soils. Over the years, we’ve refined our membranes to handle increased pressures without tearing or causing undue strain on the test setup.

Moreover, flexible membranes help replicate real-world conditions in computational models. Discrete Element Method (DEM) simulations3 rely on accurate input from lab tests. If the membrane data is skewed, so is the simulation. Engineers and researchers use these precise findings to design safer structures—everything from highways and bridges to industrial facilities. Without the faithful mimicry of a flexible membrane, we’d risk underestimating stresses in real-life situations, potentially compromising safety. By ensuring uniform stress distribution and minimal boundary interference, we create an environment where the materials behave in the lab just as they would on site.

Effect of Low Temperature on Latex Triaxial Membranes

Membranes can stiffen or become brittle in cold environments, impacting test accuracy if not properly managed.

Low temperatures can reduce a membrane’s elasticity, potentially affecting measurement fidelity and overall structural integrity.

Once, a colleague of mine conducted soil tests in a colder-than-average lab—someone cranked the AC way down to preserve sensitive samples. At the time, I wondered why the latex membranes4 seemed harder to stretch. The cold had turned them slightly rigid, making it challenging to fit them neatly around the sample. This experience taught me that, while latex membranes4 are versatile, they’re not immune to temperature shifts.

When membranes become cold, they lose some of their natural elasticity. Tiny cracks or micro-tears might appear if you force them too much. If you’re running a triaxial test5 in a low-temperature setting—say, for simulating permafrost conditions—you must factor in how the membrane’s reduced flexibility could influence your readings. In some cases, labs store membranes in temperature-controlled rooms or pre-warm them to ensure a smoother fit prior to the test. Doing so helps maintain that ideal elasticity we need for accurate data.

Beyond elasticity, cold temperatures can also affect the fluid (often water) used to apply confining pressure around the membrane. If the fluid thickens or if condensation forms, it might alter the pressure conditions, indirectly impacting the membrane’s performance. That’s why I always recommend letting the membrane acclimate to the testing environment before sealing it around the sample. Even a slight difference in temperature between the membrane and the soil can cause sudden tension points. In short, controlling temperature is a straightforward way to maintain membrane integrity6 and avoid inaccuracies in your triaxial test5ing.

Technique to avoid membrane punching during triaxial test of crushed aggregate

Crushed aggregates can penetrate the membrane if not handled correctly. But a few adjustments can prevent membrane punching.

Adding a protective layer, using thicker membranes, or ensuring proper sample compaction helps avoid membrane puncture during triaxial tests.

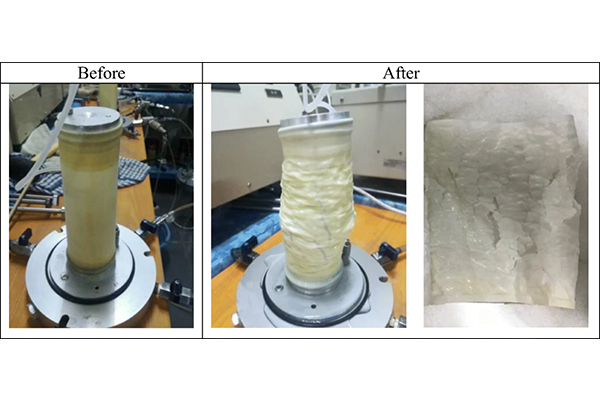

When I first heard of the term “membrane punching,” I pictured someone literally punching holes in the membrane. But in reality, it occurs when sharp or angular aggregates push against the membrane under high stress. This often happens in tests involving coarse, crushed materials. The force can be intense, so if your membrane isn’t up to the task, you’ll end up with holes or tears that ruin the test data.

A simple yet effective technique is placing a thin geotextile or filter paper between the membrane and the aggregate. This extra layer helps smooth out jagged edges, acting as a buffer to protect the latex. Some labs also select thicker latex membranes specifically for crushed aggregate tests. Though thicker membranes can slightly influence test readings, they often save time and money by preventing do-overs caused by membrane failure.

It’s also crucial to compact your sample evenly. If certain areas have bigger voids, the aggregates can shift and cause localized pressure points against the membrane. Proper sample preparation—ensuring uniform particle distribution and moisture content—lowers the risk of sudden rips. I’ve seen labs skip thorough compaction to save time, only to discover the membrane had torn mid-test, forcing them to start over. That’s frustrating for everyone involved.

And let’s not forget the importance of using quality membranes. At Howdy, our design department often recommends specialized thickness or material mixes for labs dealing with especially aggressive aggregates. Membranes with higher tensile strength and better tear resistance go a long way in keeping everything intact. Yes, the initial cost might be higher, but it beats redoing an entire round of tests because your membrane gave out at the worst possible moment.

What is the advantage of flexibility of latex membrane?

Flexibility ensures a snug fit, minimizes friction, and provides accurate data by conforming to various sample shapes.

A flexible membrane adapts to uneven surfaces, preventing measurement bias and guaranteeing reliable, repeatable triaxial test results.

I’ve come to realize that not all latex membranes are created equal. Flexibility is often the deciding factor between a successful test and a flawed one. Picture trying to wrap a delicate vase with rigid plastic—it wouldn’t conform to the vase’s curves, and any pressure could crack it. Latex membranes with higher flexibility7 act more like a soft, stretchy cloth hugging the contours of your sample. This snug fit is crucial if you’re aiming for precise test outcomes because it eliminates tiny air pockets or unfilled spaces.

Flexibility also ensures that when pressure is applied from different angles, the membrane responds uniformly. In essence, it helps replicate the true stress conditions that soil, aggregate, or other materials experience underground. If the membrane were too stiff, you’d see stress concentrations at certain points, artificially inflating or deflating your results. That was a lesson I learned early on when one of my first tests showed anomalous data. Turned out, we used a lower-grade membrane that didn’t stretch evenly, throwing off the entire analysis.

Moreover, flexible membranes are less likely to tear when dealing with odd-shaped samples. Let’s say you have a partially cohesive soil sample with lumps or pebbles inside. A rigid membrane might tear at the lumps, while a flexible one simply molds itself around them. This is particularly important for research labs aiming to simulate real-world conditions rather than “perfect” samples. Having the right elasticity also eases the setup process, reducing the time spent sealing and trimming.

Engineers and testers often stand by the mantra: “The test is only as good as its boundary conditions.” In triaxial tests, your boundary conditions are largely governed by the membrane. So, when your membrane can stretch and adapt, you end up with data that aligns more with reality. That’s why, at Howdy, we focus on ensuring consistent flexibility7 across all our membrane batches. It’s not just about making a product that fits—it’s about making a product that adapts beautifully to any shape it’s wrapped around.

Conclusion

Triaxial latex membranes shape reliable, realistic test results, ultimately boosting product durability across diverse industrial and research applications.

-

Discover the significance of large-scale triaxial test simulations in geotechnical engineering and their impact on safety and design. ↩

-

Learn about the importance of flexible latex membranes in soil testing and how they ensure accurate results in engineering. ↩

-

Explore this link to understand how DEM simulations are crucial for accurate modeling in engineering and material science. ↩

-

Understanding how temperature affects latex membranes can help you optimize their use in various applications, ensuring better performance and accuracy. ↩ ↩

-

Exploring the impact of temperature on triaxial tests can enhance your testing accuracy and reliability, crucial for geotechnical engineering. ↩ ↩

-

Learning about best practices for membrane integrity can prevent inaccuracies in your tests, leading to more reliable data and outcomes. ↩

-

Understanding the role of flexibility in latex membranes can enhance your testing accuracy and outcomes significantly. ↩ ↩