Types of Miniature Penetrometers: From Spring-Loaded to Electronic Models

Miniature penetrometers help you “listen” to soil strength inside or alongside triaxial specimens—fast, local, and often with minimal setup. But tools differ wildly in how they generate, sense, and display load. Below is a clear, lab-ready tour of the four most common types, plus where each one shines.

Spring-Loaded Penetrometers: Reliable Simplicity

Why you’d pick it: rugged, budget-friendly1, and fast to deploy at the bench or in the field.

How it works (in plain terms)

A calibrated coil spring resists the push on the tip. The force you apply correlates with penetration resistance; you read strength off a color band, pointer, or basic scale.

Strengths

- Zero electronics: no cables, no batteries, no firmware.

- Quick checks: ideal for rapid screening of soft clays and silts.

- Low training burden: technicians learn it in minutes.

Watchouts

- Rate sensitivity: push too fast and you over-read; go too slow and friction/stick–slip dominates.

- Coarse resolution: small changes near the low end can be hard to see.

- Spring aging: creep and fatigue shift calibration—plan periodic checks.

Good fit for

- On-the-fly profiling during specimen prep.

- Teaching labs and quick QA where trend matters more than decimals.

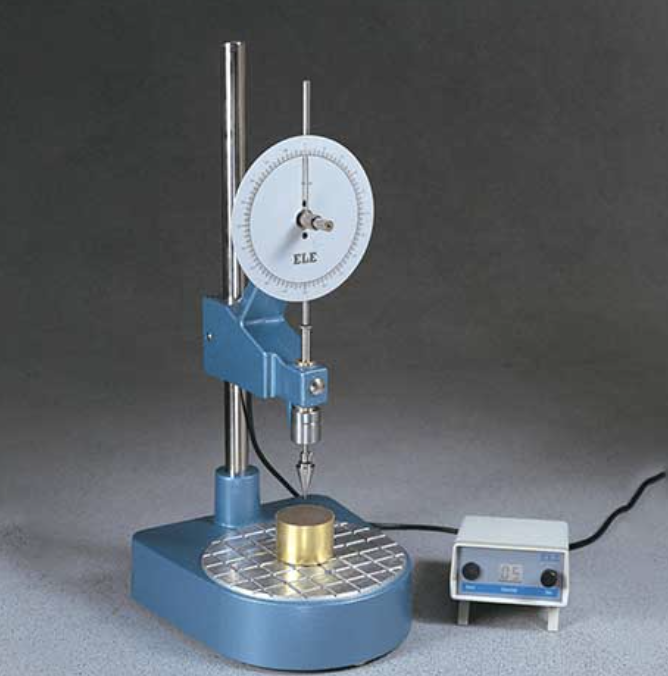

Dial Gauge Penetrometers: Precision with Clarity

Why you’d pick it: mechanical confidence with higher readability and repeatability than basic spring types.

How it works

Load is transmitted through a spring or lever to a dial indicator2 (often 0.01 mm or better). You convert dial movement to force via a known spring constant (or read force directly on force dials).

Strengths

- Fine visual readout: easy to detect small increments.

- Repeatable technique with a guide sleeve3 for alignment.

- No electronics but better metrology than basic spring sticks.

Watchouts

- Parallax & human reading: align your eye with the dial.

- Still manual: penetration rate and alignment depend on the operator.

- Calibration discipline: spring constant + tip area must be current.

Good fit for

- Labs wanting mechanical simplicity plus better resolution for soft-to-medium soils.

- Situations where power/data isn’t convenient but numbers must persuade.

Digital Penetrometers: Merging Accuracy and Efficiency

Why you’d pick it: accurate numbers with timestamps—no transcription errors, and easy syncing to your DAQ.

How it works

A miniature load cell4 (foil strain gauge or MEMS) measures force; the body includes a digital readout and often a USB/serial output. Some models log internally.

Strengths

- Higher accuracy with linearization and tare functions.

- Data capture: instant CSV/JSON logs; fewer notebook mistakes.

- Thermal compensation on better units reduces drift.

Watchouts

- Cable management: motion can tug leads—use strain relief.

- Sampling rate: ensure the internal/DAQ rate matches your penetration rate (100–500 Hz is typical for quasi-static).

- Battery/firmware: keep spares and update policies.

Good fit for

- Routine research/QA where traceability matters.

- Programs needing side-by-side plots with axial load, pore pressure, and displacement.

Electronic Models: Automation for Advanced Research

Why you’d pick it: you want the penetrometer to behave like any other actuator/sensor in your triaxial rig—scripted, synchronized, and repeatable.

How it works

An instrumented head5 (load cell + optional displacement sensor) mounts on a micro-actuator under closed-loop control. Software scripts penetration speed, dwell, multi-cycle passes, and position mapping.

Strengths

- Automation6: constant-rate penetration, fixed preloads, identical multi-point grids.

- Synchronization: time-locked with frame load, cell/back pressure, and pore pressure.

- High repeatability: operator influence drops dramatically.

Watchouts

- Cost & integration: needs motion control, I/O, and safety interlocks.

- Maintenance: actuator alignment and guide bushings must stay tight.

- Overkill for quick checks: best justified by throughput or research complexity.

Good fit for

- Advanced labs running parametric studies, rate effects, or unsaturated suction-coupled investigations.

- Validation datasets where repeatability and scripts are non-negotiable.

Quick Comparison Matrix (Print This)

|

Feature / Need | Spring-Loaded | Dial Gauge | Digital | Electronic |

|---|---|---|---|---|---|

| Power required | No | No | Yes | Yes | |

| Readout | Bands/basic | Analog dial | Numeric + export | Full DAQ integration | |

| Typical resolution | Low | Medium | Medium–High | High | |

| Rate control | Manual | Manual (guided) | Manual (logged) | Closed-loop | |

| Data traceability | Low | Medium | High | Highest | |

| Best for | Rapid screening | Budget precision | QA + research | Automated research | |

| Cost (relative) | $ | $$ | $$$ | $$$$ |

Tip Geometry & Capacity (Applies to All Types)

- Tip shape: cone for general use; flat/cylindrical for very soft materials; hardened cones for cemented/weak rocklike soils.

- Capacity sizing: aim for test peaks in 30–70% FS7 to keep the sensor in its sweet spot.

- Alignment: use a guide sleeve8; wobble = side friction = fake strength.

- Penetration rate: standardize (e.g., 0.5–2 mm/min) and log it—rate changes strength.

Calibration & Care (No Exceptions)

- Per-session: warm-up (if electronic), zero/tare, two-point check, tip inspection (10×), record tip area factor.

- Periodic: multi-point calibration (0/25/50/75/100% FS) monthly in-house; 6–12 months accredited.

- After events: overload, tip change, cable damage → recalibrate.

- Environment: keep tests within a ±1 °C band; cover specimens between passes to stabilize moisture.

Choosing by Scenario (Cheat Sheet)

- Teaching & quick shop-floor checks → Spring-loaded

- Budget lab; better numbers without electronics → Dial gauge

- QA/research; need files & plots today → Digital

- High-throughput or scripted research → Electronic (automated)

Conclusion

Start with the problem you’re solving: speed, persuasion, or automation. Pick the simplest penetrometer that delivers the resolution and traceability your program needs—then protect it with alignment, rate control, and calibration. Do that, and every penetration trace will speak clearly, test after test.

-

Exploring this link will provide insights into cost-effective tools that enhance efficiency without compromising quality. ↩

-

Understanding dial indicators can enhance your measurement accuracy and precision in various applications. ↩

-

Exploring guide sleeves can help you achieve better alignment and repeatability in your measurements. ↩

-

Understanding load cells is crucial for accurate force measurement in various applications, making this resource invaluable. ↩

-

Understanding the role of an instrumented head can enhance your knowledge of triaxial testing and its applications. ↩

-

Exploring automation in triaxial testing can reveal efficiencies and advancements that enhance research outcomes. ↩

-

Understanding the significance of 30–70% FS can enhance your knowledge of sensor performance and capacity sizing. ↩

-

Exploring the role of a guide sleeve can help you ensure accurate measurements and avoid errors in strength testing. ↩