Direct Soil Shear Testing: Understanding the Process

Direct shear testing is essential for evaluating the shear strength properties of soils, crucial for the stability of slopes, foundations, and retaining structures. By understanding this straightforward method, engineers can confidently determine how soils behave under applied forces. This article covers everything you need to know about direct shear testing.

What Is the Principle Behind Direct Shear Testing?

Direct shear testing measures the shear strength of soil1 under controlled conditions. The soil sample is placed in a shear box divided horizontally. A vertical load applies normal stress, while a horizontal force gradually shears the sample along a predetermined failure plane.

This method helps determine two essential parameters:

- Cohesion (c)2: The internal attraction between soil particles.

- Friction Angle (φ)3: Resistance due to friction between particles.

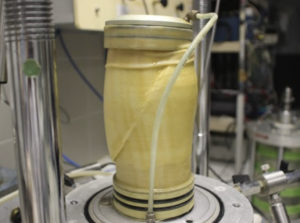

How Is the Test Sample Prepared?

Proper sample preparation ensures accurate results:

- Sample selection4: Soil is sieved, usually passing through a No. 4 sieve (4.75 mm).

- Moisture control5: Adjust soil moisture to desired testing conditions.

- Placement in shear box6: Compact the soil into two halves of the shear box uniformly to avoid density variations.

Careful sample preparation reduces errors, ensuring reliable test outcomes.

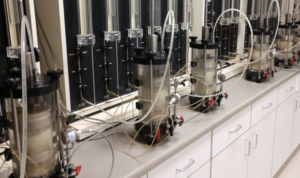

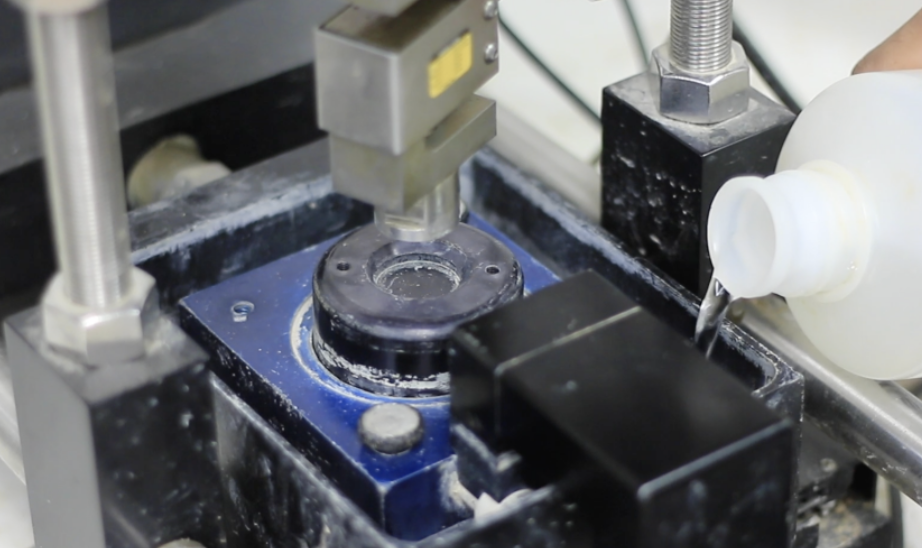

What Equipment Is Used in a Direct Shear Test?

Essential equipment includes:

- Shear box apparatus: Horizontally split box where soil sample is confined.

- Loading device: Vertical loading to apply normal stress.

- Horizontal displacement mechanism: Applies controlled horizontal shear force.

- Dial gauges or digital sensors: Measure displacement and applied loads accurately.

| Thiết bị | Mục đích |

|---|---|

| Shear Box | Contains and shears the soil sample |

| Vertical Load System | Applies and controls normal stress |

| Horizontal Mechanism | Provides controlled shearing force |

| Gauges or Sensors | Record displacements and forces |

How Are the Results Analyzed?

Data analysis involves plotting shear stress versus horizontal displacement:

- Peak shear stress7: Indicates the maximum soil strength at a given normal stress.

- Residual shear stress: Strength after significant displacement, important for long-term stability.

- Mohr-Coulomb Envelope8: A straight line drawn through multiple test results at different normal stresses to determine cohesion and friction angle.

| Tham số | Meaning and Interpretation |

|---|---|

| Sự gắn kết (c) | Soil’s internal particle bonding |

| Friction Angle (φ) | Soil’s resistance to sliding due to particle friction |

| Peak Shear Stress | Maximum strength before significant movement |

| Residual Shear Stress | Long-term strength after large displacement |

Phần kết luận

Direct shear testing provides critical data on soil strength and behavior, guiding effective and safe engineering design. Understanding its principles, proper sample preparation, equipment use, and accurate interpretation of results are key to reliable geotechnical analysis.

-

Understanding shear strength is crucial for geotechnical engineering and construction projects. Explore this link to learn more about its significance. ↩

-

Cohesion is a key factor in soil stability. Discover its role in engineering and construction by exploring this resource. ↩

-

The friction angle is vital for assessing soil behavior under load. Learn more about its implications in engineering by checking this link. ↩

-

Understanding sample selection is crucial for accurate soil testing results, ensuring reliability in your findings. ↩

-

Moisture control is vital for achieving precise soil test outcomes, making it essential to explore its impact. ↩

-

Proper placement in the shear box is key to avoiding density variations, which can skew test results. Learn more about it. ↩

-

Understanding peak shear stress is crucial for evaluating soil strength under various conditions, enhancing your knowledge in geotechnical engineering. ↩

-

Learning about the Mohr-Coulomb Envelope aids in determining soil properties, essential for effective engineering design and analysis. ↩