Bao thanh toán về khả năng lưu lượng của vật liệu hạt: chọn thiết bị phòng thí nghiệm tốt nhất

When dealing with granular materials, understanding and measuring flowability is crucial for accurate handling, testing, and processing in the lab. Selecting appropriate equipment that accommodates flow characteristics ensures precise results and smoother laboratory workflows.

Which Lab Tools Are Most Sensitive to Flowability?

Certain lab instruments are particularly sensitive to material flowability, including:

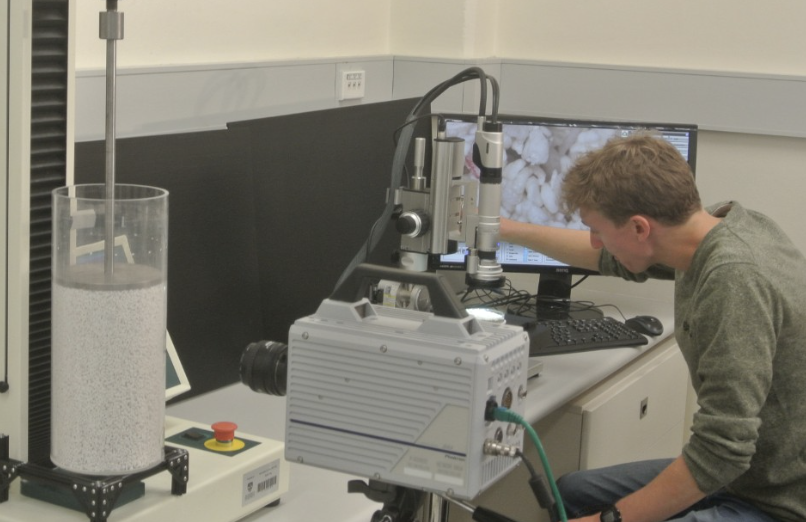

- Powder Flow Testers1: Measure precise flow characteristics such as angle of repose and flow rate.

- Sieve Shakers2: Sensitive to particle flow, critical for reliable size distribution results.

- Spinning Rifflers: Require uniform particle flow to achieve accurate sample division.

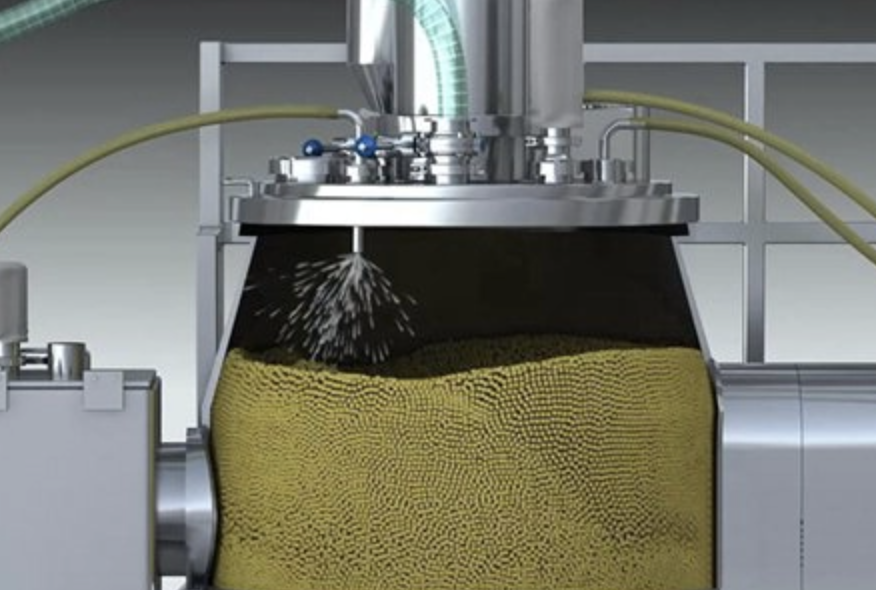

- Hoppers and Feeders3: Directly impacted by flowability for consistent material feeding.

Selecting the right tools designed to handle specific flow properties prevents operational disruptions and enhances lab efficiency.

How to Measure Flowability Before Equipment Selection?

Accurately assessing flowability involves several reliable techniques:

- Angle of Repose Test: Measures the steepness of the slope formed by granular material.

- Carr’s Index & Hausner Ratio: Evaluate compressibility and flow potential.

- Shear Cell Testing: Determines cohesive strength and flow characteristics under pressure.

| Phương pháp | Measurement | Ứng dụng |

|---|---|---|

| Angle of Repose | Simple flowability indication | General initial assessments |

| Carr’s Index | Compressibility and cohesiveness | Powders and fine granular materials |

| Shear Cell | Detailed cohesive strength analysis | Precise industrial applications |

What Design Features Improve Equipment Performance?

Certain design elements significantly improve handling and performance with granular materials:

- Smooth, Non-Stick Surfaces4: Prevent particle build-up and clogging.

- Adjustable Apertures and Gates5: Allow control over material flow rate.

- Conical or Funnel-Shaped Containers: Facilitate consistent gravity-fed flow.

- Modular and Easy-to-Clean Components6: Improve maintenance efficiency and reduce downtime.

High-quality design features reduce interruptions caused by poor flowability, enhancing the reliability and longevity of lab equipment.

When Should You Use Vibration or Air Assist?

Some granular materials require assistance for consistent flow, especially when dealing with cohesive or sticky particles:

- Vibration7: Helps break friction between particles, promoting uniform material movement. Ideal for moderately cohesive or irregularly shaped particles.

- Air Assist (Aeration)8: Introduces air to reduce particle-to-particle friction, effectively managing very fine, cohesive powders.

| Assistance Method | Recommended Use Case |

|---|---|

| Vibration | Medium-cohesive powders, irregular particles |

| Air Assist | Highly cohesive, fine powders |

Understanding when to implement these aids ensures continuous, trouble-free operation.

Phần kết luận

Properly factoring in granular material flowability before choosing lab equipment is essential. By carefully evaluating flow characteristics, selecting sensitive instruments, and using supportive design features, laboratories achieve higher accuracy, improved productivity, and consistent performance.

-

Explore this link to find top-rated Powder Flow Testers that ensure accurate measurement of flow characteristics, enhancing lab efficiency. ↩

-

Discover how Sieve Shakers play a crucial role in achieving reliable size distribution results, vital for your lab’s success. ↩

-

Learn about the significance of Hoppers and Feeders in maintaining consistent material feeding, essential for operational efficiency. ↩

-

Explore how smooth non-stick surfaces can enhance performance and prevent clogging in granular material handling. ↩

-

Learn about the importance of adjustable apertures and gates in controlling material flow rates effectively. ↩

-

Discover how modular designs can enhance maintenance efficiency and reduce downtime in lab settings. ↩

-

Understanding the role of vibration can enhance your knowledge of material handling and processing techniques. ↩

-

Exploring air assist techniques can provide insights into effective management of fine powders in various industries. ↩