How to Select the Right Laboratory Jaw Crusher for Your Needs?

Choosing the right laboratory jaw crusher1 can make or break the success of your material testing workflow. From sample integrity to throughput efficiency, a properly selected crusher ensures reliable results and smooth lab operations. But with so many models and configurations available, where do you begin? Here’s a step-by-step guide to help you make the right decision based on your actual needs.

Assessing Material Types and Hardness Requirements

Not all materials behave the same under pressure. The type of material you plan to crush2—whether it’s soft clay, dense ore, or brittle ceramic—will influence the jaw material, crushing power, and wear resistance needed.

Key Questions to Ask:

- Is your sample abrasive, metallic, brittle, or moist?

- Does it contain hard minerals like quartz or basalt?

- Are contamination-free conditions necessary for trace element testing?

| Loại vật chất | Recommended Jaw Material | Hardness Range (Mohs) |

|---|---|---|

| Silica-rich ores | Tungsten carbide or hardened steel | 6–9 |

| General rock samples | Hardened steel | 3–7 |

| Ceramic/Glass | Manganese steel or ceramic | 5–7 |

| Clean metal alloys | Ceramic or chromium-free steel | 4–8 |

Tip: For ultra-sensitive testing (e.g. ICP or XRF), choose non-ferrous jaws to avoid cross-contamination.

Evaluating Capacity and Throughput Needs

Every lab has different demands. Whether you’re crushing a few grams or several kilograms a day, selecting a crusher with the right throughput capacity3 is critical.

Consider:

- Sample volume per day or per test cycle

- Required output size4 (e.g. 2 mm for sieving or 0.5 mm for digestion)

- Whether continuous or batch processing5 is preferred

| Requirement Type | Ideal Crusher Throughput |

|---|---|

| Low-volume research | 100–300 kg/h |

| University labs | 300–600 kg/h |

| Industrial R&D labs | 600–1,000+ kg/h |

Overloading an undersized crusher leads to faster wear and poor sample quality—while overinvesting in an oversized unit wastes money and space.

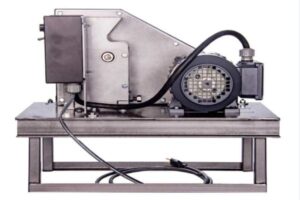

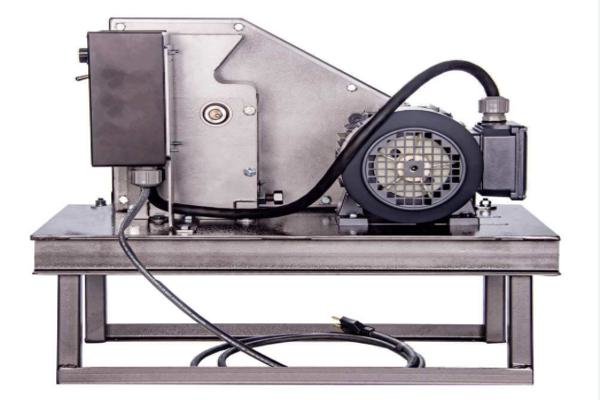

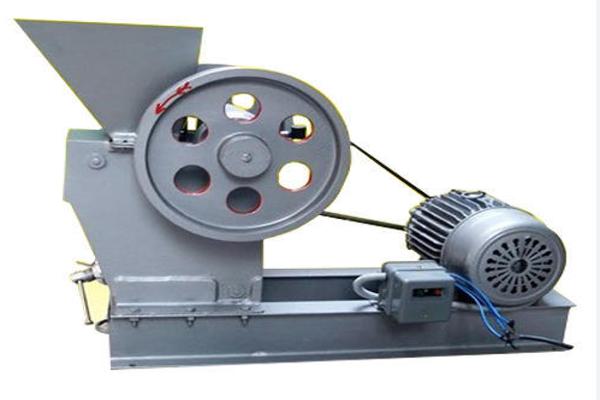

Considering Size and Space Constraints in the Lab

Lab environments are often tight on space6. The physical dimensions and setup requirements of the jaw crusher7 must match your lab’s layout and workflow8.

Factors to Consider:

- Do you have a benchtop or floor-standing space available?

- Is there access to ventilation for dust extraction?

- What about electrical compatibility (e.g., 220V vs. 110V)?

| Crusher Type | Footprint | Best Use Case |

|---|---|---|

| Benchtop | ~50×40 cm | Small academic or field labs |

| Mid-size floor model | ~80×70 cm | General-purpose lab work |

| Large high-throughput | >100×80 cm | Industrial material testing |

Pro Tip: Look for models with casters or modular trays for easier repositioning and cleaning.

Weighing Cost-Effectiveness Against Performance Requirements

Budget always matters, but so does long-term value. A cost-effective lab jaw crusher balances performance with maintenance, energy use, and lifespan.

Total Cost Considerations:

- Initial price vs. jaw plate replacement frequency

- Energy consumption and runtime per sample batch

- Manufacturer support, spare parts availability, and warranty

| Budget Level | Features You Can Expect |

|---|---|

| Entry-level | Basic adjustability, steel jaws, lower duty |

| Mid-range | Better materials, safety enclosures, more control |

| Premium | Contamination-free, advanced automation, higher output |

Always align the price with your specific lab needs, not just the spec sheet.

Phần kết luận

Selecting the right laboratory jaw crusher isn’t just about specs—it’s about matching your material, volume, space, and budget to the right crushing tool. Whether you’re breaking down ore for elemental analysis or preparing ceramics for mechanical testing, the right crusher will give you accurate, clean, and consistent results—test after test.

-

Explore this link to discover top-rated laboratory jaw crushers that enhance sample integrity and throughput efficiency, ensuring reliable results. ↩

-

Understanding the factors that influence material selection can enhance your crushing efficiency and equipment longevity. ↩

-

Understanding the significance of throughput capacity can help you choose the best crusher for your lab’s needs, ensuring efficiency and productivity. ↩

-

Output size directly impacts the quality of test results. Discover why it’s essential to choose the right output size for your needs. ↩

-

Choosing between continuous and batch processing can significantly affect productivity. Learn the pros and cons of each method here. ↩

-

Understanding the challenges of limited space in labs can help optimize your workflow and equipment placement. ↩

-

Exploring jaw crusher specifications will ensure you select the right model for your lab’s needs and space constraints. ↩

-

Learning about efficient lab layouts can enhance productivity and make the best use of available space. ↩