What is Axial Stress in Triaxial Test?

Axial stress is a critical parameter in triaxial testing, providing insight into the mechanical behavior of soils and rocks under controlled conditions. It plays a vital role in determining shear strength, deformation characteristics, and failure mechanisms, making it indispensable in geotechnical engineering.

Understanding Axial Stress in Triaxial Testing

Axial stress in a triaxial test refers to the vertical load applied to a cylindrical soil or rock sample while it is subjected to a confining pressure. This stress is used to simulate real-world loading conditions that foundations, slopes, and tunnels experience. The total axial stress1 ((\sigma_1)) in the test is defined as:

[\sigma_1 = \frac{P}{A}]

where:

- ( P ) = applied axial load (force),

- ( A ) = cross-sectional area of the specimen.

Axial stress is responsible for initiating failure in the soil sample by increasing deviatoric stress2 ((\sigma_1 – \sigma_3)), which ultimately determines shear strength.

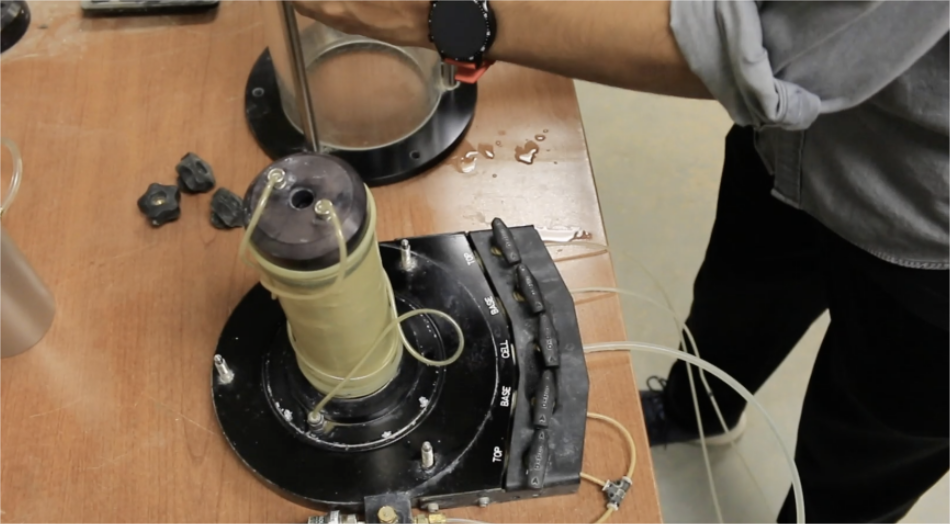

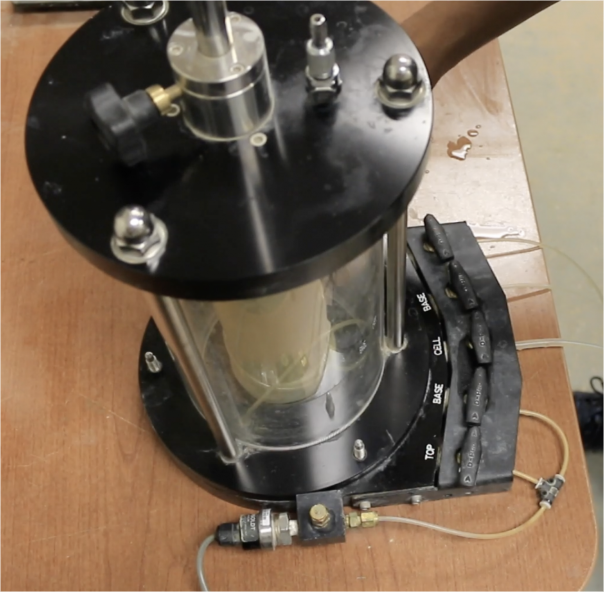

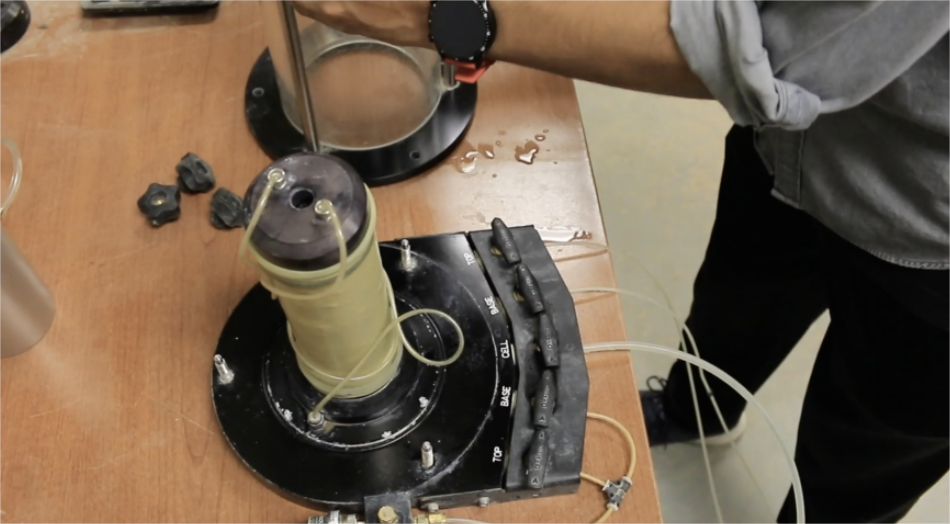

How Axial Stress is Applied in a Triaxial Test

The triaxial test applies axial stress through a loading piston while maintaining a constant lateral confining pressure ((\sigma_3)). The test is typically conducted in three different modes:

-

Unconsolidated Undrained (UU) Test:

- Axial stress is applied quickly without allowing drainage.

- Measures undrained shear strength3, relevant for short-term stability analyses.

-

Consolidated Undrained (CU) Test:

- The sample is allowed to consolidate before axial loading.

- Measures effective stress parameters4 while considering pore pressure effects.

-

Consolidated Drained (CD) Test:

- Drainage is permitted during axial stress application.

- Provides long-term strength parameters5 under drained conditions.

Each method provides unique insights into soil behavior under different loading and drainage scenarios.

Axial Stress vs. Deviatoric Stress

Deviatoric stress ((\sigma_d)) is the difference between axial and confining stresses:

[\sigma_d = \sigma_1 – \sigma_3]

This stress governs failure, making it a key parameter in geotechnical design.

The Role of Axial Stress in Soil and Rock Mechanics

Axial stress influences critical engineering properties, including:

- Shear Strength6: Determines the maximum stress a soil or rock can withstand before failure.

- Deformation Behavior7: Governs how soil contracts, expands, or fractures under loading.

- Pore Pressure Response8: In undrained conditions, axial stress impacts pore pressure buildup, which affects stability.

Experimental results show different stress-strain responses depending on soil type:

| Soil Type | Peak Axial Stress ((\sigma_1)) | Failure Mode |

|---|---|---|

| Loose Sand | 100–250 kPa | Dilation (Expands) |

| Dense Sand | 300–600 kPa | Brittle Failure |

| Soft Clay | 50–150 kPa | Plastic Flow |

| Stiff Clay | 200–500 kPa | Brittle to Ductile |

Understanding these behaviors ensures safe and efficient geotechnical designs.

Interpreting Axial Stress for Strength Analysis

Axial stress data is crucial for deriving key soil parameters used in engineering analysis:

-

Mohr-Coulomb Failure Criteria:

- The relationship between normal and shear stress at failure is expressed as:

[\tau = c + \sigma \tan\phi]

- Where:

- ( c ) = cohesion,

- ( \phi ) = friction angle.

-

Stress-Strain Curves:

- The shape of the axial stress-strain curve helps determine stiffness, peak strength, and failure behavior.

-

Factor of Safety (FoS):

- Axial stress results contribute to stability assessments of slopes, foundations, and retaining walls.

Comparative Strength Analysis of Different Soils

| Parameter | Sandy Soil | Clayey Soil |

|---|---|---|

| Peak Axial Stress ((\sigma_1)) | High (>300 kPa) | Moderate (50-200 kPa) |

| Pore Pressure Response | Low | High in undrained conditions |

| Failure Type | Brittle | Ductile or Flow |

By carefully interpreting axial stress behavior, engineers can predict how soils will perform under real-world conditions, ensuring safer infrastructure.

Conclusion

Axial stress in triaxial testing plays a fundamental role in understanding soil and rock behavior under loading. By controlling axial stress and analyzing its effects on deformation and strength, engineers can design safer and more reliable foundations, slopes, and tunnels. Whether in drained or undrained conditions, the correct interpretation of axial stress data is essential for geotechnical engineering success.

-

Understanding axial stress is crucial for interpreting triaxial test results and their implications in geotechnical engineering. ↩

-

Learning about deviatoric stress helps in understanding failure mechanisms in soils, which is vital for safe engineering practices. ↩

-

Understanding undrained shear strength is crucial for assessing soil stability in construction projects. Explore this link for detailed insights. ↩

-

Effective stress parameters are vital for predicting soil behavior under load. Discover more about their significance in this informative resource. ↩

-

Long-term strength parameters help in evaluating soil performance over time. Learn more about their importance in engineering applications. ↩

-

Understanding shear strength is crucial for predicting material failure and ensuring structural integrity in engineering projects. ↩

-

Exploring deformation behavior helps engineers design safer structures by anticipating soil reactions under load. ↩

-

Investigating pore pressure response is vital for managing stability in geotechnical engineering, especially in undrained conditions. ↩