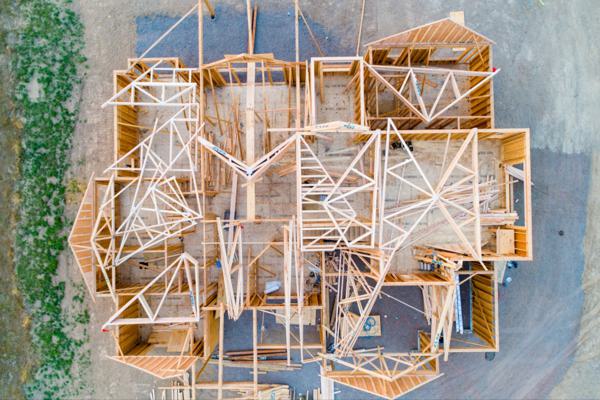

How Did Testing Save the Day for a Timber-Framed Building Project?

Timber-framed buildings are admired for their warmth, sustainability, and speed of construction. But even the best-laid blueprints can fall apart without careful attention to material quality1. In one such project, testing didn’t just catch a problem—it saved the entire structure from potential long-term failure2. Here’s how it all unfolded.

The Original Plan and Material Selection for the Timber-Framed Building

The project began as a mid-sized community center with a modern, exposed timber frame design3. The architect chose spruce and laminated veneer lumber (LVL) for the primary beams and columns due to their lightweight strength and aesthetic appeal. The building was set in a humid, coastal climate, so resistance to moisture and biological degradation4 was critical.

The contractor sourced timber from a local mill with FSC certification. Everything appeared to be on schedule—until the quality assurance team began standard material testing5.

Moisture Content and Density Testing of Timber Materials

As per best practices, the testing team began with basic physical property tests:

Moisture and Density Tests Conducted:

- Moisture Content (ASTM D4442) using oven-dry method

- Density Testing (ASTM D2395) to assess strength classification

- Grain orientation and knot frequency analysis

| Timber Sample ID | Moisture Content (%) | Expected Range (%) | Density (kg/m³) |

|---|---|---|---|

| Beam-A1 | 23.5 | 12–18 | 480 |

| Column-B2 | 21.9 | 12–18 | 465 |

| LVL-C3 | 17.2 | 12–18 | 510 |

Results showed that several beams exceeded moisture limits, increasing the risk of warping, mold, and fungal decay—especially problematic in a coastal zone.

The team flagged this immediately. But what came next was even more unexpected.

Discovery of Decay-Prone Areas Through Non-Destructive Testing

To prevent dismantling installed sections, the team employed non-destructive testing (NDT)6 to scan structural timbers:

NDT Tools Used:

- Resistograph testing7 for internal wood density

- Ultrasound velocity testing (ASTM D6760) to identify voids and delaminations

- Infrared thermography to spot hidden moisture gradients

These tests revealed:

- Early signs of internal decay in two main support beams.

- Voids and low-density pockets within glulam members likely due to incomplete curing or storage errors.

- Elevated internal moisture levels near window junctions where flashing had not yet been installed.

| Location | NDT Finding | Risk Level |

|---|---|---|

| Beam A1 (core) | Low resistograph reading, decay zone | High (replace) |

| LVL C2 (joint) | Internal moisture > 22% | Medium (seal + dry) |

| Column B3 | Velocity drop, possible void | Medium (monitor) |

Without testing, these flaws could have remained invisible—until structural degradation or even failure occurred years later.

Final Decisions Made After Comprehensive Test Analyses

After compiling the test results, the project team made swift, informed decisions:

- Two load-bearing beams were replaced with kiln-dried, factory-certified timber.

- Protective coatings were applied to remaining components to prevent moisture ingress.

- Drying time was extended for borderline materials, with retesting before final assembly.

- On-site storage practices were revised, including raised pallets and dehumidified containers.

The most important change? The team instituted a new policy requiring in-situ testing of all structural timbers before installation. This delayed the schedule slightly—but likely prevented a long-term structural disaster.

Conclusion

This project proved one powerful truth: timber doesn’t lie—but it needs to be tested to tell the truth. What began as a standard inspection uncovered flaws that could have jeopardized the entire build. Thanks to early testing, smart diagnostics, and decisive action, the team preserved both the vision and the integrity of the timber-framed building. In the end, testing didn’t just catch a problem—it built confidence from the ground up.

-

Understanding material quality is crucial for ensuring the longevity and safety of timber-framed buildings. Explore this link to learn more. ↩

-

Discover how proactive testing can safeguard structures and prevent costly failures in the future. This resource provides valuable insights. ↩

-

Explore this link to understand how modern timber frame designs enhance aesthetics and functionality in buildings. ↩

-

Learn about the importance of moisture resistance in construction materials to ensure longevity and durability. ↩

-

Discover the critical role of quality assurance in ensuring the safety and reliability of construction materials. ↩

-

Explore this link to understand the principles and benefits of NDT in various industries, enhancing your knowledge on structural integrity assessment. ↩

-

Learn about Resistograph testing to see how it accurately measures wood density, crucial for evaluating structural health. ↩