Triaxial Testing in Energy Exploration: Shale Gas, Hydrates, and Beyond

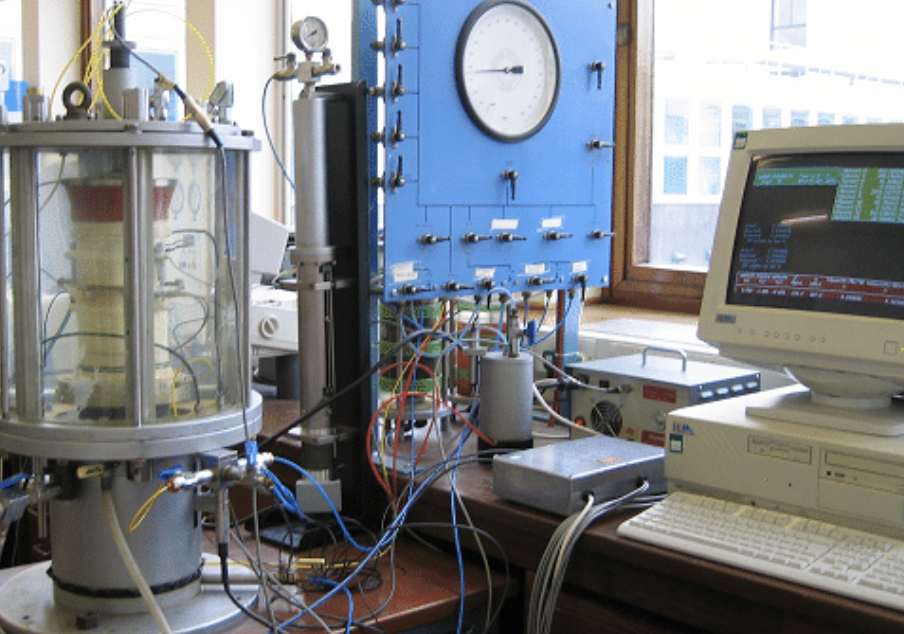

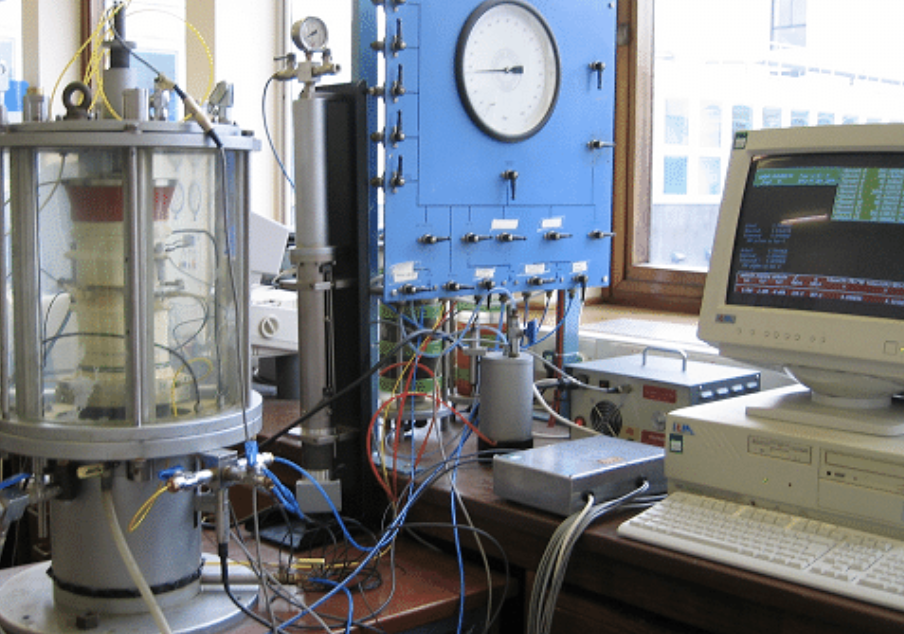

In the ever-evolving quest for energy, understanding how subsurface materials respond to stress is crucial. Triaxial testing—a technique long used in geotechnical engineering—is now central to evaluating rock integrity, reservoir behavior, and extraction risks in energy exploration. From shale gas to methane hydrates, and even future geothermal and carbon storage sites, triaxial tests reveal the mechanical secrets of energy-bearing formations—ensuring both safety and sustainability in the field.

Assessing Shale Gas Reservoir Integrity under Stress Conditions

Shale gas extraction relies on hydraulic fracturing, which creates networks of cracks in low-permeability rocks. But not all shale formations respond the same way. Triaxial tests help assess the strength, brittleness, and fracture potential of shale under simulated in-situ stress conditions.

Key Parameters Measured:

- Unconfined compressive strength (UCS)

- Failure envelope and cohesion

- Elastic modulus

- Brittleness index

Example: Shale Behavior Under Triaxial Compression

| Shale Type | UCS (MPa) | Brittleness Index | Fracture Propensity |

|---|---|---|---|

| Barnett Shale | 82 | High (0.7) | High |

| Marcellus Shale | 58 | Moderate (0.5) | Medium |

| Utica Shale | 110 | Low (0.3) | Low |

These insights help engineers optimize fracture designs, minimize risk of casing failure, and reduce seismic hazards.

Evaluating Methane Hydrate Stability in Deep-Sea Environments

Methane hydrates—often found in permafrost or oceanic sediments—are a potential unconventional energy source1, but they’re notoriously unstable. Triaxial testing under low-temperature, high-pressure conditions2 simulates how hydrates behave under drilling, pressure changes, or warming.

Key Focus Areas:

- Shear strength degradation during dissociation

- Volumetric expansion risks (blowouts)

- Pore pressure evolution

- Thermo-mechanical coupling effects

Lab Simulation Parameters

| Test Variable | Range |

|---|---|

| Temperature | –5°C to +10°C |

| Confining Pressure | 5–30 MPa |

| Hydrate Saturation | 40–80% |

| Strain Rate | 0.1–5%/min |

Such tests are vital to ensure safe hydrate extraction and seabed stability, especially in fragile offshore zones.

Enhancing Wellbore Stability through Rock Strength Characterization

Wellbore failure during drilling can lead to costly delays, equipment damage, and safety risks3. Triaxial tests allow geomechanical engineers to build reliable strength and failure models4 for rocks encountered at various depths.

What Triaxial Tests Reveal:

- Strength anisotropy in laminated or fractured formations

- Pore pressure influence5 on rock deformation

- Breakout and collapse pressure thresholds

- Elastic-plastic behavior under dynamic loading

Stress Path Analysis Example

| Formation Depth (m) | Vertical Stress (MPa) | Shear Failure Predicted | Recommended Mud Weight (g/cm³) |

|---|---|---|---|

| 2,500 | 55 | Yes | 1.80 |

| 3,200 | 71 | No | 1.65 |

Triaxial testing is instrumental in preventing borehole collapse and designing cost-effective drilling plans.

Future Frontiers: Geothermal and CO₂ Sequestration Applications

As the energy sector transitions to low-carbon and renewable alternatives6, triaxial testing continues to expand its relevance.

Geothermal Energy:

- Evaluates thermal cracking and fatigue7 of hot dry rock.

- Assesses fracture permeability at elevated temperatures and pressures.

Carbon Capture and Storage (CCS):

- Determines caprock integrity8 under CO₂ injection pressures.

- Predicts long-term mechanical stability of depleted reservoirs.

Experimental Conditions Comparison

| Application | Typical Temp (°C) | Pressure (MPa) | Key Concern |

|---|---|---|---|

| Geothermal | 150–300 | 10–25 | Thermo-mechanical stress |

| CO₂ Sequestration | 30–90 | 20–40 | Caprock sealing, creep |

Triaxial tests in these contexts help ensure that clean energy projects remain safe, viable, and long-lasting.

Conclusion

Triaxial testing is no longer just a geotechnical tool—it’s a pillar of modern energy exploration and sustainability. By revealing how materials behave under realistic subsurface conditions, it helps engineers unlock resources safely, stabilize drilling operations, and plan for a carbon-conscious future. Whether extracting gas, harnessing geothermal heat, or storing CO₂, the power to understand stress and strength lies at the core of every responsible energy decision.

-

Exploring this link will provide insights into the future of energy and the role of unconventional sources like methane hydrates. ↩

-

Understanding these conditions is crucial for safe drilling and energy extraction from methane hydrates. ↩

-

Understanding these impacts can help in planning and risk management for drilling operations. ↩

-

Exploring this topic can enhance your knowledge of rock mechanics and improve drilling strategies. ↩

-

This knowledge is crucial for predicting rock behavior and ensuring safe drilling practices. ↩

-

Explore this link to understand the latest trends and technologies in low-carbon and renewable energy alternatives, crucial for a sustainable future. ↩

-

Learn about thermal cracking and fatigue to grasp their impact on geothermal energy efficiency and reliability, essential for energy innovation. ↩

-

Discover the importance of caprock integrity in CCS to understand its role in safe and effective carbon storage solutions. ↩