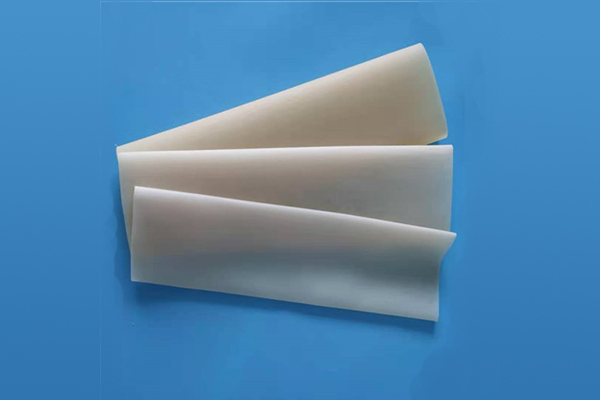

Triaxial latex membranes fascinate me with their flexibility and how they enhance precise, reliable testing in so many industries.

Triaxial latex membranes provide waterproofing and elasticity, ensuring stable conditions for accurate testing and durable product outcomes.

They’re simpler than you might think, yet vital to modern test procedures.

What is Latex membrane waterproofing?

Latex membrane waterproofing keeps moisture out, creating a protective barrier for various applications.

Latex membranes form a flexible, water-resistant seal that prevents leaks and material damage in testing environments.

I still recall the first time I tested a latex membrane in a damp environment. The lab was bustling, and the soil samples were slightly soggy—traces of water everywhere. I noticed how the membrane effortlessly hugged the sample, shielding it from external moisture. It struck me that this flexible film wasn’t just a random piece of rubber; it was the key to preserving the sample’s integrity.

Latex membrane waterproofing matters because unwanted moisture can completely skew test results. When you’re analyzing soil strength1, for instance, even a small amount of extra water can change the soil’s behavior under stress. By creating a watertight seal2, the membrane ensures that the sample’s internal moisture content stays stable, producing more accurate data.

Beyond geotechnical labs, latex membranes play a role in other industries, too. Some businesses use them to test the water resistance of new building materials or to protect sensitive electronics during stress tests. At Howdy, we’ve supplied membranes to labs that simulate tropical storms, sealing off the test samples so engineers can measure how different structures fare against intense humidity and water pressure. Without a quality waterproofing element, those teams would be guessing rather than knowing. And when it comes to designing safe buildings or reliable products, guessing is never the best plan.

What are the advantages of latex?

Latex offers elasticity, durability, and an impressive ability to adapt to irregular shapes—while staying surprisingly cost-effective.

Latex membranes stand out for their flexibility, tear resistance, and budget-friendly production, making them ideal for various testing needs.

I often compare latex to a good friend who’s always there when you need them—strong yet surprisingly gentle. The elasticity is the first thing you notice: it can stretch to fit complex forms without tearing. If you’re testing something oddly shaped, latex can hug every contour, ensuring even pressure distribution for more accurate test data.

Durability is another big plus. A well-made latex membrane can handle significant stress without springing leaks or tearing prematurely. At Howdy, I’ve seen membranes tested to their limits with tough materials like crushed aggregates. The fact that they maintain integrity under those conditions shows just how robust latex can be.

Cost-effectiveness is also worth noting. Unlike some high-tech materials that need special handling or expensive manufacturing processes, latex is relatively straightforward to produce at scale. This affordability makes it an attractive choice for labs on tight budgets or large companies running frequent tests. Plus, because latex membranes often last through multiple tests—assuming you handle them with care—you end up saving on replacement costs.

And then there’s the environmental angle. Latex, especially natural rubber latex, is biodegradable and renewable, although you do need to be mindful of sourcing. For many labs aiming to reduce their environmental footprint, latex can be a more sustainable choice than synthetic alternatives. It’s a well-rounded option that checks a lot of boxes—strength, versatility, and simplicity.

Why is latex Membranes so popular?

Latex membranes are popular for striking a balance between performance and ease of use, making them a go-to for testing solutions.

They’re cost-friendly, easy to install, and reliably deliver precise test data, boosting their widespread acceptance across industries.

Popularity often comes down to trust. People trust latex membranes3 because they’ve proven themselves over decades in fields like geotechnical engineering4, construction, and even product testing. When I talk to seasoned engineers, they always mention how latex is the “old reliable.” It’s been around for so long that labs know exactly how to handle it, interpret data from it, and fix any hiccups that occur.

There’s also a sort of universal familiarity with latex. I’ve seen global companies that might be wary of adopting brand-new materials—simply because newness can bring unknown complications. Latex, on the other hand, has a consistent track record. This reduces uncertainty, especially when you’re doing critical tests where accuracy can impact public safety or major financial investments.

Another factor is the simplicity of setup. Because latex membranes3 are flexible, they’re easier to place around samples without specialized tools. At one of our demonstration stands during an exhibition, folks were surprised at how smoothly the membrane molded around different soil cores. Fewer air pockets, fewer wrinkles—meaning fewer errors in your final measurements.

Finally, latex remains relatively affordable, and for labs running test after test, expenses add up. Having a membrane material that hits performance markers without breaking the bank naturally boosts its popularity. Plus, if something does go wrong, latex is easy to replace or tweak. You don’t lose weeks searching for specialized resources or spare parts. That quick turnaround fosters confidence and keeps testing cycles efficient.

What is Latex Membranes best used for?

Latex membranes excel in triaxial tests, soil analysis, and any scenario needing a waterproof, flexible barrier.

They offer a perfect blend of elasticity and durability, making them indispensable in geotechnical labs and construction testing.

When I think of latex membranes, triaxial testing5 is the first thing that pops into my mind. That’s where they truly shine—forming a tight, uniform seal around soil or aggregate specimens. Because the test demands accurate pressure distribution, a properly fitted latex membrane ensures every layer of the sample experiences stress consistently. I’ve watched as an entire lab’s day was saved by simply switching to a quality latex membrane that delivered cleaner, more uniform test data.

But that’s not the only place latex dominates. If you’re experimenting with new building materials—like concrete mixes or asphalt—latex membranes can keep outside moisture from contaminating the sample. They can also protect sensitive products during vibration or shock tests by maintaining a consistent barrier. I know some clients who even use them in fluid containment tests, verifying how different liquids interact with certain samples under various pressures in a controlled setting.

And let’s not ignore the fact that latex membranes are handy in large-scale environmental simulations6. Engineers might replicate flooding or freezing conditions to see how soils react when water levels rise or temperatures plummet. Latex membranes hold everything together, ensuring the only variable is the environment—no leaks or infiltration messing with the results.

At Howdy, we’ve also provided membranes for universities and research institutes investigating next-gen composites. They appreciate how quick and easy it is to set up. The less time spent fussing with the membrane, the more time they have to focus on analyzing data. Whether you’re an industry veteran or an academic researcher, the membrane’s best trait is its adaptability—it morphs to fit different shapes, applications, and stress levels, consistently delivering reliable outcomes.

Conclusion

Latex membranes excel at balancing flexibility, durability, and affordability—key elements that make testing more efficient and results more trustworthy.

-

Soil strength analysis is vital for safe construction practices, ensuring structures can withstand environmental stresses and loads. ↩

-

A watertight seal is essential for maintaining sample integrity, leading to more precise data in experiments and analyses. ↩

-

Explore the advantages of latex membranes, including their reliability and cost-effectiveness in various applications. ↩ ↩

-

Learn how geotechnical engineering leverages latex membranes for accurate and efficient testing processes. ↩

-

Learn about triaxial testing methods and their importance in soil mechanics, ensuring precise results in your projects. ↩

-

Discover how environmental simulations can help engineers understand material behavior under extreme conditions, improving design strategies. ↩

2 Responses