What is ASR in Concrete?

ASR stands for Alkali-Silica Reaction—a slow but damaging chemical reaction that can cause cracking and expansion in concrete. It’s often called “concrete cancer” because once it starts, it can be very difficult to stop. ASR affects the durability and lifespan of concrete structures and is a major concern for engineers, especially in bridges, pavements, and dams.

Understanding the Chemistry Behind ASR

ASR happens when alkalis (sodium and potassium) in cement react with reactive silica found in certain types of aggregate. This reaction forms a gel-like substance that swells when it absorbs moisture.

The Reaction Process:

- Alkalis + Reactive Silica → Alkali–Silica Gel

- Gel + Moisture → Swelling and Expansion

- Expansion → Internal Pressure → Cracking

| Reactant | Source |

|---|---|

| Alkalis (Na⁺, K⁺) | Portland cement, admixtures |

| Reactive Silica | Volcanic rock, chert, opal |

| Moisture | Groundwater, rain |

This chemical reaction is slow but cumulative, often taking years to visibly damage the structure.

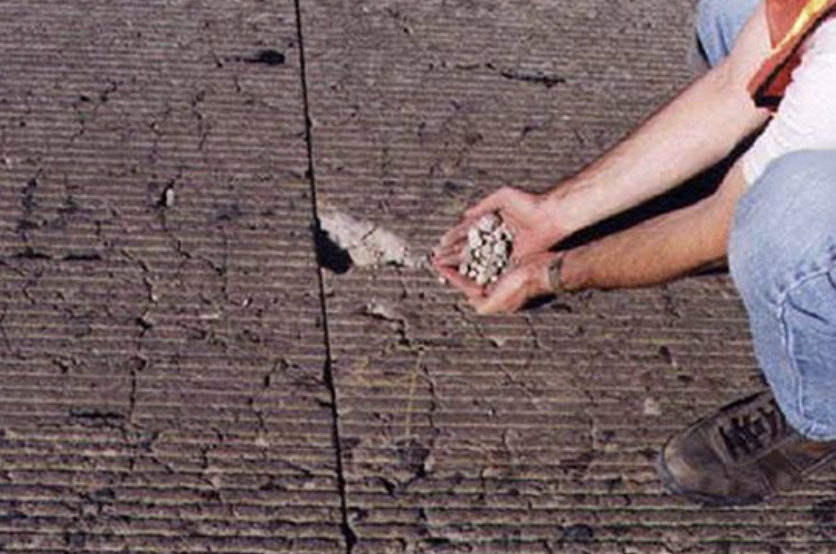

Common Symptoms of ASR Damage

Recognizing the signs of ASR is critical for early intervention. Structures affected by ASR often display progressive surface and internal damage1.

Visible Symptoms Include:

- Map or pattern cracking2 (also called “crazing”)

- Gel exudation3 on the surface (a sticky white residue)

- Joint displacement and surface deformation

- Pop-outs or surface spalling

| Symptom | What It Suggests |

|---|---|

| Fine, web-like cracks | Early-stage ASR |

| Cracks near joints or corners | Advanced internal swelling |

| White crystalline deposits | Gel exuding to surface |

These symptoms may appear 10–15 years after construction, especially in moist environments.

Prevention and Control Methods

Although ASR is serious, it can be prevented or mitigated4 by careful material selection and concrete mix design.

Prevention Strategies:

- Use low-alkali cement5 (≤ 0.60% Na₂O equivalent)

- Select non-reactive aggregates6 (screen using ASTM C295, C1260)

- Add pozzolanic materials like fly ash or silica fume to bind alkalis

- Control moisture exposure (good drainage and waterproofing)

| Control Method | Effectiveness |

|---|---|

| Low-alkali cement | Reduces alkali availability |

| Supplementary cementitious materials | Ties up free alkalis, slows reaction |

| Moisture control | Starves the gel of water |

The key is to address all three ingredients of the ASR reaction: alkalis, reactive silica, and moisture.

ASR in Infrastructure: Risks and Consequences

ASR poses serious risks to critical infrastructure7. While it doesn’t usually cause sudden failure, the progressive weakening8 can lead to expensive repairs and safety concerns.

Risks Include:

- Loss of structural integrity

- Increased permeability9, leading to corrosion of reinforcement

- Reduced load-bearing capacity

- Service disruption in roads, airports, bridges, and dams

| Structure Type | ASR Impact |

|---|---|

| Highway pavements | Cracking, uneven surfaces |

| Bridge decks | Expansion, joint failure |

| Dams | Deformation, water leakage |

| Parking structures | Surface scaling, rebar corrosion |

Mitigating ASR is crucial for extending service life and ensuring public safety in aging concrete assets.

Conclusion

ASR is a silent but serious threat to concrete durability. Understanding the chemistry, spotting the signs early, and using preventive measures can help engineers and builders protect structures from long-term damage. In today’s infrastructure challenges, managing ASR isn’t just good practice—it’s essential for building resilient and sustainable concrete systems.

-

Understanding the implications of this damage can help in early detection and intervention for ASR. ↩

-

Exploring this topic can provide insights into the mechanisms behind ASR and its prevention. ↩

-

Learning about gel exudation can enhance your knowledge of ASR symptoms and their impact on structural integrity. ↩

-

Explore this resource to understand comprehensive strategies for preventing ASR, ensuring the longevity and durability of concrete structures. ↩

-

Learn about low-alkali cement and its role in reducing ASR risk, which is crucial for sustainable construction practices. ↩

-

Discover the importance of non-reactive aggregates in concrete mix design to effectively combat ASR and enhance structural integrity. ↩

-

Understanding the risks to critical infrastructure is essential for ensuring safety and preventing costly repairs. Explore this link for in-depth insights. ↩

-

Learn about the implications of progressive weakening on structures and how it can lead to significant safety issues and costs. ↩

-

Discover how increased permeability can lead to corrosion and structural failures, which is crucial for maintaining infrastructure integrity. ↩