Common Mistakes When Using Latex Membranes in Triaxial Tests—and How to Avoid Them

Latex membranes may look like minor components, but in triaxial tests, they play a major role in sealing the soil specimen and ensuring accurate measurements.

Mistakes in selecting, installing, or maintaining latex membranes can lead to leaks, test failures, and inaccurate data. By understanding these common errors, you can avoid wasted time and costly re-tests.

Why Improper Membrane Selection Leads to Test Failures

Choosing the wrong membrane is the first—and most common—mistake.

If the latex membrane1 is too thin, it may tear under confining pressure. Too thick, and it can distort the stress distribution2 on the specimen, altering the test results.

Common Selection Errors:

- Using a thin membrane for coarse or sharp-grained soils

- Selecting incorrect diameter, causing overstretching or loose fitting

- Ignoring compatibility with high-pressure conditions

| Membrane Issue | Likely Problem |

|---|---|

| Too thin | Tears under pressure or rough soil |

| Too thick | Alters stress-strain measurements |

| Wrong diameter/length | Wrinkles or leaks |

Solution: Always match membrane thickness (0.3–0.8 mm) and diameter to the specimen type and expected confining pressures.

How Poor Installation Causes Leaks and Data Errors

Even with the correct membrane, bad installation can ruin your test.

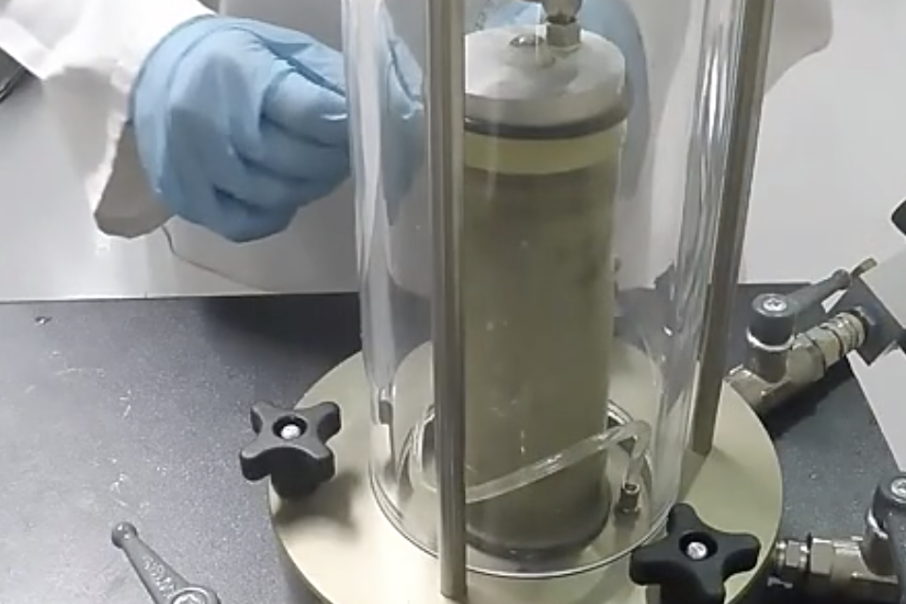

Improper rolling3, air bubbles4, or uneven O-ring placement can cause leaks that skew data or cause the test to fail altogether.

Installation Mistakes:

- Stretching the membrane unevenly

- Trapping air pockets between the soil and the membrane

- Misplacing O-rings, leading to a poor seal

| Step | Mistake to Avoid |

|---|---|

| Membrane stretching | Overstretching weakens latex |

| Rolling on sample | Wrinkles create uneven stress zones |

| Sealing | Loose O-rings cause confining leaks |

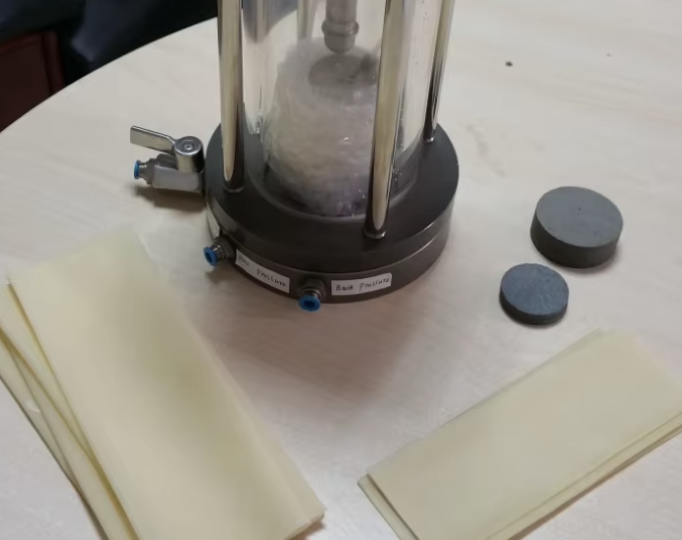

Solution: Use a proper membrane stretcher and a vacuum system to ensure a smooth, bubble-free fit. Always double-check seals before testing.

The Impact of Neglecting Thickness and Size Tolerances

Latex membranes are sensitive to thickness and size variations.

If the membrane thickness5 varies too much, it can cause inconsistent confining stress, resulting in unreliable shear strength values6.

Issues Caused by Incorrect Tolerances:

- Uneven wall thickness7 leading to asymmetric pressure application

- Excessively loose membranes8 reducing specimen stability

- Too tight a fit, increasing side friction and measurement errors

| Parameter | Recommended Tolerance |

|---|---|

| Thickness | ±0.02 mm for accurate testing |

| Diameter | 2–5% smaller than specimen size |

| Length | Enough for 10–15 mm sealing margin |

Solution: Choose high-quality membranes with consistent manufacturing standards. Verify dimensions before use.

Best Practices to Prevent Contamination and Damage

Membranes can fail not only from mechanical stress but also from contamination or poor handling.

Contact with oils, dust, or sharp objects weakens latex and leads to premature failure.

Avoid These Damage Risks:

- Handling with oily or dirty hands

- Storing in direct sunlight or high heat

- Skipping cleaning and inspection between tests

| Prevention Step | Why It Matters |

|---|---|

| Use gloves | Prevents oil contamination |

| Store in cool, dark place | Prolongs membrane elasticity |

| Inspect before testing | Identifies cracks or pinholes early |

Solution: Store membranes in sealed, opaque bags at 10–20°C, and clean them with de-aired water after each test.

Conclusion

Most problems with latex membranes in triaxial tests come down to selection, installation, or handling errors. By choosing the right thickness and size, installing carefully, and maintaining proper storage, you’ll avoid leaks, improve data accuracy, and save valuable lab time.

A well-chosen and well-handled membrane isn’t just a detail—it’s the foundation of reliable soil test results.

-

Understanding the best practices for selecting a latex membrane can help ensure accurate test results and prevent common mistakes. ↩

-

Exploring how stress distribution impacts test results can provide valuable insights into material testing accuracy and reliability. ↩

-

Understanding the impact of improper rolling can help ensure accurate test results and prevent costly errors. ↩

-

Exploring the effects of air bubbles can provide insights into maintaining test integrity and achieving reliable outcomes. ↩

-

Understanding the relationship between membrane thickness and shear strength is crucial for ensuring reliable performance in applications. ↩

-

Exploring this topic can provide insights into material performance and help in making informed engineering decisions. ↩

-

Understanding the impact of wall thickness can enhance your design and structural integrity knowledge. ↩

-

Exploring this topic can provide insights into improving experimental setups and results. ↩