How Do You Select the Right Latex Membrane for Triaxial Testing?

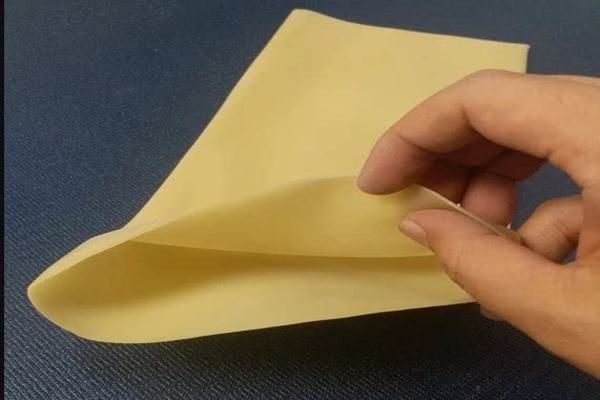

Selecting an appropriate latex membrane is critical for achieving accurate and repeatable triaxial test results. The membrane must effectively isolate the soil specimen while accommodating deformation and maintaining integrity under stress. Below, we explore key considerations to guide the selection process.

Assessing Membrane Permeability

A primary function of a latex membrane in triaxial testing is to prevent unwanted fluid exchange between the soil specimen and the confining medium. Therefore, it is essential to evaluate the membrane’s permeability:

- Low Permeability Requirement1: The membrane should act as an effective barrier, ensuring that the pore water within the specimen remains undisturbed during the test.

- Testing for Leakage2: Prior to use, membranes should be tested for potential leaks or pinholes that might compromise test conditions.

- Material Consistency3: Uniform permeability across the membrane’s surface is vital for even stress distribution and accurate pore pressure measurements.

A well-selected membrane with low permeability ensures that the sample’s saturation and drainage conditions remain controlled throughout the experiment.

Determining the Appropriate Thickness and Strength

The membrane’s thickness and mechanical strength are crucial parameters that influence its performance under test conditions:

- Thickness Guidelines4: The membrane must be thick enough to withstand high confining pressures and axial loads, yet thin enough to minimize restraint on the specimen. Many standards suggest that the unstretched membrane diameter should be between 90–95% of the specimen diameter, with thickness typically not exceeding 1% of the specimen’s diameter.

- Mechanical Strength5: High tensile strength and elongation capacity are required to endure the forces during consolidation and shearing without rupturing.

- Consistency in Properties[6]: Ensure that the membrane material provides uniform strength and thickness to avoid local stress concentrations that might alter the test outcome.

Selecting a membrane with the correct balance of thickness and strength is key to preserving the natural behavior of the soil specimen during testing.

Considering Stress and Deformation Conditions

The stress path in a triaxial test imposes various mechanical loads on the membrane. The selected membrane must be compatible with these conditions:

- Flexibility vs. Rigidity6: The membrane must be flexible enough to conform closely to the specimen’s shape without inducing additional stresses. However, it should not be so compliant that it deforms excessively and interferes with the test measurements.

- Stress Distribution: A proper membrane ensures uniform distribution of confining pressure, reducing the risk of localized stress peaks.

- Impact on Test Data7: The membrane’s behavior under stress may require corrections in the measured data. Understanding its mechanical properties (e.g., Young’s modulus) helps in calibrating the system and accounting for any membrane-induced effects.

Evaluating the membrane under simulated stress conditions can ensure that it performs reliably during the actual test.

Ensuring Proper Membrane Handling and Storage

Even the best membrane can fail if not handled or stored correctly. Key practices include:

- Inspection Before Use: Check the membrane for defects such as pinholes, tears, or uneven thickness before installation.

- Clean Handling: Use gloves and clean tools to prevent contamination, which can compromise membrane performance.

- Proper Storage: Store membranes in a cool, dry, and dust-free environment. Avoid exposure to extreme temperatures or direct sunlight, as these can degrade the material.

- Careful Installation: Ensure the membrane is installed without wrinkles or slack; use appropriate tools (e.g., membrane expanders) to achieve a tight, uniform seal around the specimen.

Good handling and storage practices help maintain the membrane’s integrity, ensuring consistent test performance and longevity.

Conclusion

Selecting the right latex membrane for triaxial testing involves a careful assessment of permeability, thickness, strength, and compatibility with stress conditions. By ensuring proper handling and storage, engineers can maintain the membrane’s performance, leading to reliable and accurate soil test results. This attention to detail ultimately improves the interpretation of soil behavior under load, supporting safer and more efficient geotechnical designs.

-

Understanding low permeability in membranes is crucial for accurate soil testing results. Explore this link to learn more about its significance. ↩

-

Leak testing is essential for ensuring the integrity of soil tests. Discover effective methods for testing membranes against leaks. ↩

-

Material consistency affects test accuracy and reliability. Learn why it’s vital for effective triaxial testing results. ↩

-

Understanding thickness guidelines is crucial for ensuring accurate soil testing results and preserving specimen integrity. ↩

-

Exploring the importance of mechanical strength can help you choose the right membrane for reliable soil testing outcomes. ↩

-

Understanding the balance between flexibility and rigidity in membranes is crucial for accurate triaxial test results. Explore this link for detailed insights. ↩

-

Discover how membrane properties influence test data accuracy and the necessary corrections for reliable results. ↩