Practical Tips for Handling Latex Membranes with a Membrane Stretcher

A clean, wrinkle-free membrane install is the fastest way to better B-values and fewer leaks in triaxial tests. Here’s a field-tested, technician-friendly guide you can apply today.

How Should You Prepare the Membrane and Stretcher?

Goal: zero nicks, even stretch, no contamination.

Prep checklist

- Inspect & polish: Make sure stretcher lips are rounded and the bore is mirror-smooth1. Remove burrs on the pedestal/top cap.

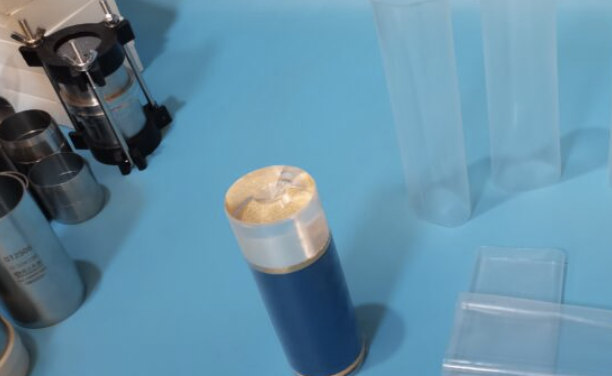

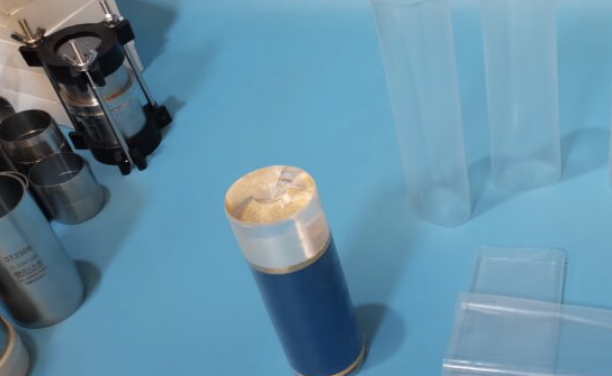

- Size match: Target ~2–5% stretch when the sleeve is on the specimen (snug, not stressed).

- Clean handling: Nitrile gloves, oil-free hands. Oils weaken latex.

- Temper the sleeve: Bring membranes to room temperature (cold latex is brittle).

- Light wetting: Wipe a film of de-aired water2 (or a drop of glycerin in water) on the stretcher—never heavy lubrication.

- Stage parts: Porous stones seated, heights checked, O-rings ready.

Membrane thickness quick guide

| Soil type / surface | Recommended thickness |

|---|---|

| Soft clays, sensitive | 0.3–0.4 mm |

| Silts & fine sands | 0.5–0.6 mm |

| Coarse / angular | 0.7–0.8 mm (or sacrificial under-sleeve) |

What Is the Correct Way to Apply Vacuum?

(For vacuum stretchers; skip if using manual only.)

- Leak check first: Cap the port, pull vacuum, spray soapy water3 on fittings; fix any bubbles.

- Moisture trap inline: Protect the pump with a cold/moisture trap4; drain weekly.

- Set the target: Aim for −70 to −85 kPa (gauge) at the stretcher. Verify with a gauge at point-of-use.

- Seat the sleeve: With vacuum applied, the membrane should “hug” the tube evenly—no fluttering edges.

- Slow transfer: Align over the specimen and unroll steadily. Keep the vacuum on until the lower third is seated, then taper off.

- Decay test (optional): With ports closed, vacuum loss <5 kPa in 60 s indicates tight seals.

Do not: slam full vacuum onto a very thin sleeve or soft specimen—rushing can cause bridging or micro-tears.

How Can You Avoid Membrane Slippage?

Common causes: oversize sleeve, oily seats, single O-ring, or handling twists.

Practical fixes

- Right diameter: If the sleeve sits slack, step down a size.

- Double O-rings: Top and bottom. Inspect grooves for nicks; keep lands clean and dry.

- De-grease seats: Wipe pedestal/top-cap lands with lint-free tissue before seating.

- Add micro-grip: Thin filter paper drains5 or ribbed seats help; they also improve drainage.

- Bottom-up flooding: During saturation, flow from the base to push air up and keep the sleeve seated.

- Handle as a unit: Support pedestal + top cap6 together; avoid twisting the specimen.

Fast reference

| Symptom | Likely cause | Fix |

|---|---|---|

| Sleeve creeps upward | Oversize sleeve / oily land | Smaller sleeve; clean land; double O-rings |

| O-rings “walk” off | Shallow groove / uneven compression | Replace O-rings; verify groove depth; seat evenly |

| Bridging at ends | Uneven roll / dry surface | Re-roll with light wetting; maintain steady tension |

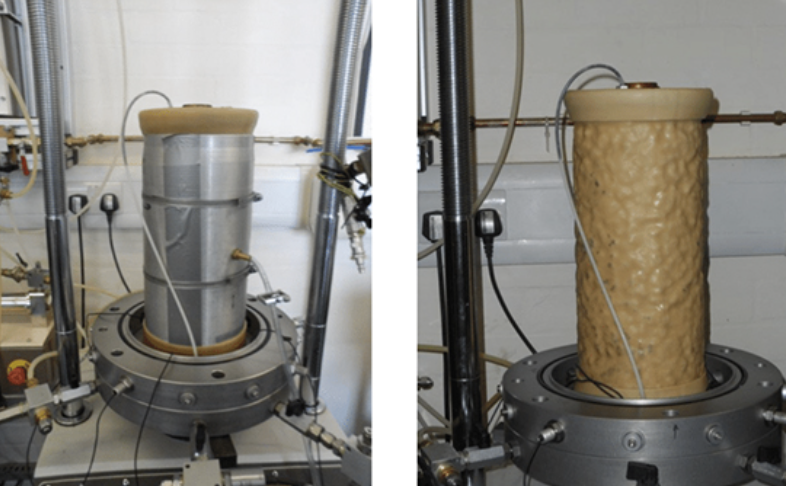

Why Is Gentle Handling Crucial?

Because specimen integrity and membrane health directly control pore-pressure fidelity and shear response.

- Less disturbance = truer curves: Rough handling smears or fissures soft clays, altering stiffness and peak/critical behavior.

- Avoid micro-cracks: Overstretching and sharp edges create pinholes that only show up under confining pressure7.

- Repeatability: A calm, repeatable motion reduces operator variance—your B-checks will cluster higher and tighter.

Gentle-handling rules

- Slow, continuous roll; no jerks.

- Keep tension even around the circumference.

- Fix small folds immediately—don’t “hope them away.”

- After seating, inspect under bright light8: no wrinkles, no air pockets, O-rings flat and parallel.

Quick Routine (Start-to-Saturation)

- Inspect/polish lips → stage stones, cap, O-rings

- Preload membrane; lightly wet stretcher

- Roll on smoothly; double O-rings top/bottom

- Bottom-up flood with de-aired water; bleed at the top

- Leak check; proceed to back-pressure saturation and B-check

Troubleshooting Matrix

| Issue | Root cause | First fix | If persistent |

|---|---|---|---|

| Membrane tears on entry | Sharp lip / over-stretch | Round & polish; reduce stretch | Use thicker sleeve / larger ID stretcher |

| Trapped bubbles | Fast roll / dry surface | Slow down; light wetting | Re-evacuate lines & stones; bottom-up flood |

| Won’t hold vacuum | Fitting/O-ring leak | Soapy water test; replace seals | Shorten lines; add moisture trap; upsize pump |

| Persistent wrinkles | Oversize sleeve | Correct diameter | Vacuum stretcher; re-roll with steady tension |

Conclusion

Perfect membrane installs are built on prep, controlled vacuum, secure seating, and gentle hands. Get those right, and you’ll see faster setups, higher B-values, fewer leaks, and cleaner stress–strain data—every single run.

-

Understanding 'mirror-smooth' can enhance your knowledge of quality standards in manufacturing processes. ↩

-

Exploring the uses of de-aired water can provide insights into its importance in various applications, including latex handling. ↩

-

Exploring this resource will provide you with effective techniques for using soapy water in leak detection, ensuring accurate results. ↩

-

Understanding the function of a cold/moisture trap can enhance your vacuum system's efficiency and longevity, making this resource invaluable. ↩

-

Understanding filter paper drains can enhance your knowledge of effective drainage solutions. ↩

-

Learning about the correct handling of pedestal and top cap can prevent damage and ensure better performance. ↩

-

Understanding this concept is crucial for analyzing material behavior under stress, enhancing your knowledge in engineering and geology. ↩

-

This practice ensures quality control, helping to identify defects that could compromise product integrity. ↩