Troubleshooting Common Issues with Membrane Stretchers in Triaxial Testing

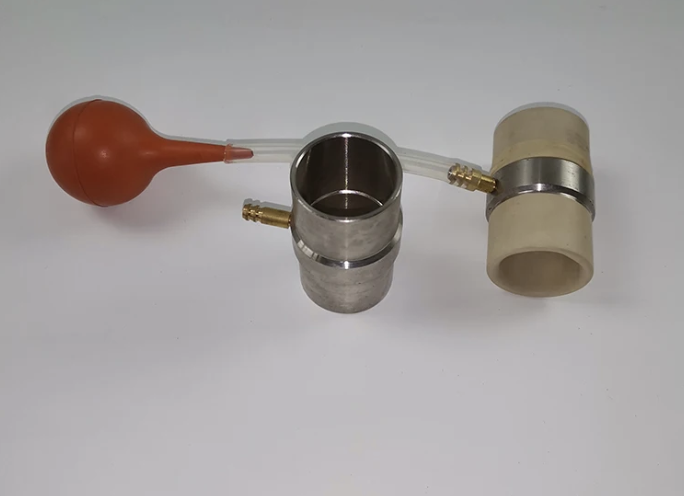

A membrane stretcher should make life easier—faster installs, fewer leaks, higher B-values. When it doesn’t, the culprit is usually technique, sizing, or vacuum integrity. Below is a lab-tested playbook to diagnose and fix the most common problems in minutes, not hours.

Why Do Membranes Tear During Installation?

Typical root causes

- Overstretching a thin sleeve (e.g., 0.3 mm) on a tight ID stretcher

- Sharp edges / scratches on stretcher lips or pedestal/top-cap shoulders

- Dry friction (no wetting) or oily contamination (weakens latex)

- Cold, brittle membranes straight from storage

- Coarse or angular specimens snagging the sleeve

Fast fixes

- Match sizes: stretcher ID ≈ specimen Ø; aim for 2–5% stretch only

- Polish & round all edges; remove burrs; use a flared/tapered entry

- Wetting film: wipe a thin layer of de-aired water (or a drop of glycerin in water) on the stretcher

- Warm the sleeve to room temp (not hot) to improve elasticity

- Use protection for rough surfaces: thin sacrificial sleeve or filter paper drains before the main membrane

- Choose thickness wisely:

- Soft clays: 0.3–0.4 mm

- Silty/sandy: 0.5–0.6 mm

- Coarse/rough: 0.7–0.8 mm

| Quick checklist (tears at… → likely cause) | Location of tear | Likely cause | Fix |

|---|---|---|---|

| Lip/entry edge | Burr/scratch | Re-polish; add chamfer | |

| Mid-height band | Excess stretch1 | Use larger ID or thicker membrane | |

| Near O-ring seat | Nicked groove / over-tight O-ring2 | Inspect groove; use double O-rings with even compression |

How to Fix Vacuum Leakage in Membrane Stretchers?

Symptoms

- Membrane won’t “hug” the tube under suction

- Audible hiss; vacuum gauge won’t reach setpoint

- Bubbles persist in de-airing stage

Likely causes

- Loose or cracked vacuum fittings, perished O-rings, worn ferrules

- Moisture carryover flooding the line (weakening vacuum)

- Permeable tubing (e.g., silicone) or long runs with many tees

- Pump undersized for multi-cell demand

Step-by-step remedy

- Leak test: cap the stretcher; pull vacuum; spray soapy water3 over joints; watch for bubbles

- Seal health: replace O-rings/ferrules; grease lightly if specified by manufacturer

- Upgrade lines: switch to PTFE/PFA4 or stainless; shorten runs; remove unnecessary tees

- Add traps: cold/moisture trap between stretcher and pump; drain weekly

- Verify capacity: for multi-cell labs, size for peak use (target −70 to −85 kPa gauge at the stretcher)

Decay test rule of thumb: with ports closed, vacuum decay should be Caution:** Any added layer changes drainage slightly. Keep materials thin, consistent, and document them in your test records (ASTM/BS notes).

At-a-Glance Troubleshooting Matrix

| Symptom | Most probable cause | First action | If still present |

|---|---|---|---|

| Sleeve tears on entry | Sharp lip / overstretch | Polish; reduce stretch to 2–5% | Use thicker sleeve / larger ID |

| Won’t hold vacuum | Fitting/O-ring leak | Soapy-water check; replace seals | Shorten lines; add moisture trap |

| Sleeve creeps / slips | Oversize or oily seats | Double O-rings; de-grease seats | Add drain strips; ribbed seats |

| Persistent wrinkles | Oversize sleeve / uneven roll | Refit with correct diameter | Use vacuum stretcher; slow roll |

| Bubbles under sleeve | Dry surface / fast roll | Lightly wet; bottom-up flood | Re-evacuate lines & stones |

Best-Practice Prep (Quick Routine)

- Inspect & polish stretcher lips; confirm size match

- Pre-load membrane; bring to room temperature

- Light wetting with de-aired water; no oils on hands or seats

- Slow, even unroll; fix folds immediately

- Double O-rings; verify seating lands are clean and nick-free

- Bottom-up flood; perform a quick vacuum/bleed check

- Log it: note membrane thickness, diameter, and any auxiliary layers

Conclusion

Most stretcher problems come down to fit, finish, and vacuum integrity. Smooth edges, correct diameters, clean seating surfaces, and a tight vacuum path turn a fragile step into a reliable, repeatable procedure—delivering higher B-values, fewer leaks, and cleaner stress–strain curves.

-

Understanding the causes of excess stretch can help you choose the right membrane for your application. ↩

-

Exploring solutions for nicked grooves and over-tight O-rings can prevent future leaks and improve seal performance. ↩

-

Exploring this resource will provide you with effective techniques for using soapy water in leak detection, ensuring accurate results. ↩

-

This link will help you understand the advantages of PTFE/PFA materials, enhancing your knowledge for better upgrades in your systems. ↩