What Are the Types of Soil Failure in Triaxial Test?

In geotechnical engineering, the triaxial test is a powerful tool for understanding how soil behaves under stress. One of the most insightful outcomes of this test is observing how soil fails—each failure mode reveals unique information about the material’s strength, cohesion, and internal friction. This article explores the main types of soil failure observed during triaxial testing, including their visual characteristics, underlying mechanics, and engineering implications.

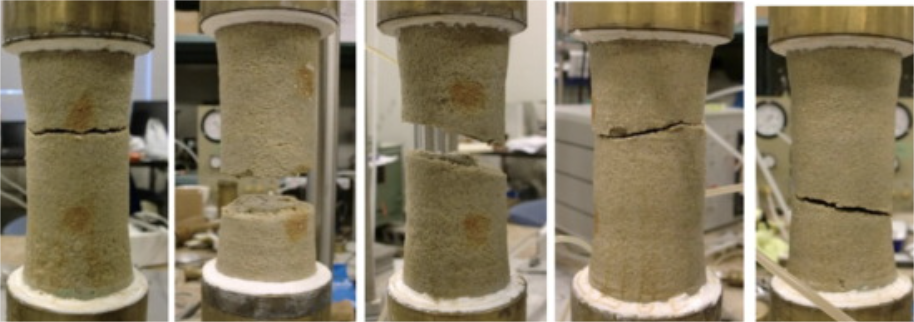

Shear Failure (Brittle Failure)

Shear failure—also called brittle failure1—is the most commonly observed mode, especially in dense sands, dry clays, and stiff soils. In this case, the soil fails along a distinct shear plane, which forms at an angle of approximately 45° to the vertical axis, due to maximum shear stress.

Key Characteristics:

- Sudden loss of strength after peak stress.

- Formation of a clean, well-defined failure plane2.

- Minimal volume change (in dry or dense soils).

- Often associated with high-friction and low-cohesion materials.

Engineering Implications:

- Indicates a brittle response, which can lead to catastrophic failure in slopes and foundations if not accounted for.

- Requires designs that limit deviator stress to prevent sudden collapse.

| Soil Type | Typical Friction Angle (φ) | Failure Nature |

|---|---|---|

| Dense Sand | 35–45° | Brittle Shear Plane |

| Stiff Clay | 20–30° | Shear Fracture |

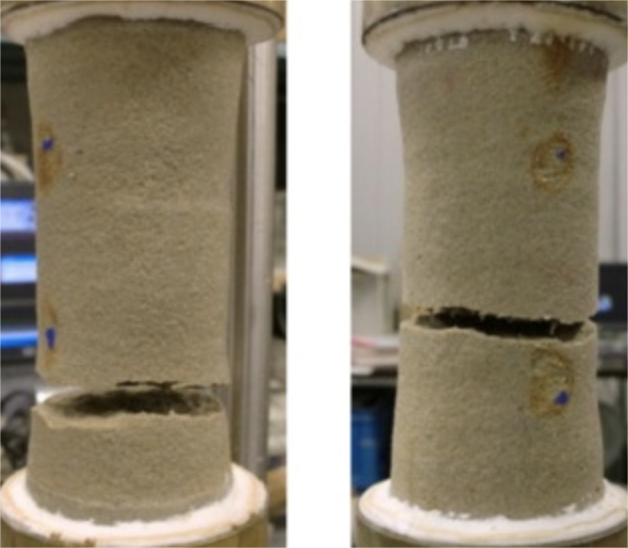

Bulging Failure

Bulging failure occurs primarily in soft clays or saturated fine-grained soils3, where the specimen expands laterally without forming a clean shear plane. The middle portion of the specimen bulges outward, and the failure is gradual and ductile in nature.

Key Characteristics:

- Rounded specimen with uniform lateral expansion.

- No visible shear plane.

- Associated with plastic deformation4.

- Occurs under low confining pressure and undrained conditions.

Engineering Implications:

- Indicates a ductile material5 that deforms without sudden breakage.

- Useful for evaluating long-term settlements and serviceability rather than abrupt failure.

| Soil Type | Void Ratio (e) | Failure Mode |

|---|---|---|

| Soft Clay | > 1.0 | Ductile Bulging |

| Peaty Soils | High | Swelling Bulge |

Localized Failure (Shear Banding)

Localized failure, also known as shear banding6, is when deformation becomes concentrated in a narrow zone, often forming a visible but irregular shear band. It is common in soils that soften after peak strength, such as over-consolidated clays and dense silts.

Key Characteristics:

- Formation of a narrow, diagonal shear zone.

- Accompanied by a drop in post-peak strength7.

- Shear strain localizes rather than spreading evenly.

- Difficult to detect in early test stages.

Engineering Implications:

- Indicates strain-softening behavior8, which can compromise slope stability and increase landslide risk.

- Highlights the need for reinforcement or drainage control in design.

| Soil Type | Consolidation Ratio (OCR) | Shear Band Behavior |

|---|---|---|

| Overconsolidated Clay | > 4 | Brittle Shear Band |

| Silty Soil | Moderate | Irregular Banding |

Compression Failure (Axial Splitting)

In some triaxial tests, particularly with cemented or structured soils, failure occurs through axial splitting. This compression failure is similar to column buckling, where the specimen splits vertically rather than forming a diagonal shear surface.

Key Characteristics:

- Vertical cracking or splitting along the axis.

- Often occurs in cemented or lightly bonded soils.

- Associated with low lateral support (low σ₃).

- Little to no shear plane formation.

Engineering Implications:

- Suggests the material behaves like a brittle rock or cemented structure.

- Designs must consider tensile splitting and crack propagation.

| Soil Type | Cementation Level | Failure Type |

|---|---|---|

| Structured Clay | Medium to High | Axial Split |

| Calcareous Sand | Cemented | Vertical Fractures |

Conclusion

The type of soil failure in a triaxial test reveals critical information about shear strength, ductility, and strain behavior. Whether it’s shear failure, bulging, shear banding, or axial splitting, each failure mode helps engineers tailor foundation, slope, and infrastructure designs to the unique properties of the soil. Understanding these failure types ensures that geotechnical solutions are not just strong—but safe and resilient.

-

Understanding brittle failure is crucial for engineers to prevent catastrophic failures in structures. ↩

-

Exploring this concept helps in designing safer structures by recognizing failure patterns in soils. ↩

-

Understanding the properties of these soils is crucial for predicting bulging failure and ensuring safe engineering practices. ↩

-

Exploring plastic deformation helps in grasping how materials behave under stress, which is vital for engineering applications. ↩

-

Learning about ductile materials can enhance your knowledge of material selection for construction and design, ensuring durability and safety. ↩

-

Understanding shear banding is crucial for predicting soil behavior under stress, which can impact construction and safety. ↩

-

Exploring this topic can help engineers design safer structures by understanding soil failure mechanisms. ↩

-

Learning about strain-softening behavior is essential for assessing slope stability and preventing landslides. ↩