What is the Difference Between Direct Shear Test and Triaxial Test?

When it comes to evaluating soil strength, two widely used laboratory methods come to mind: the Direct Shear Test and the Triaxial Test. Both are essential tools in geotechnical engineering, but they differ significantly in how they are conducted, what they measure, and how reliable their results are under varying conditions. Understanding these differences is key to selecting the right method for your project’s goals and constraints.

Test Setup and Apparatus

The most obvious difference lies in how each test is set up and the equipment used.

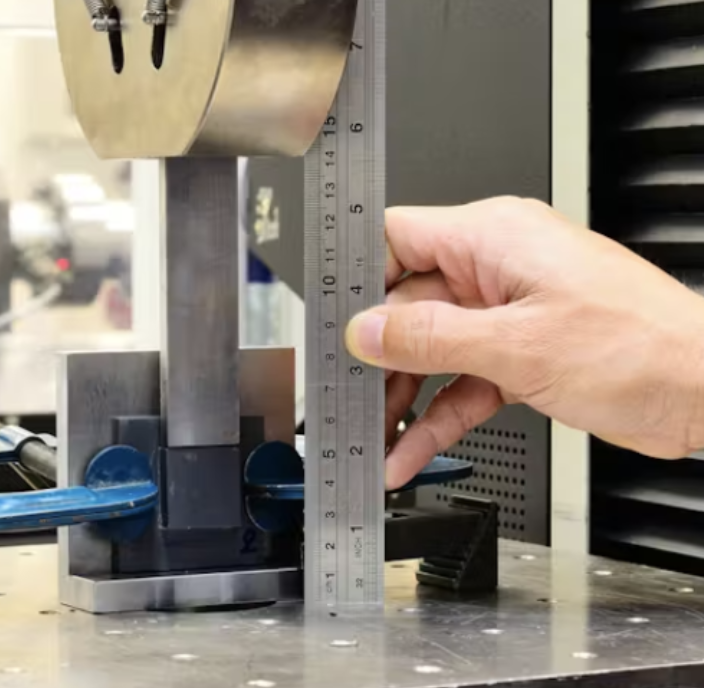

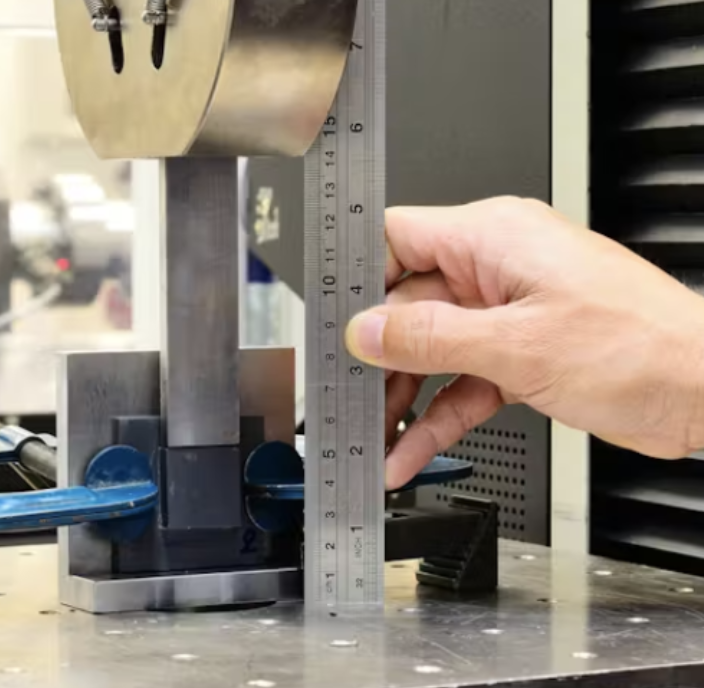

Direct Shear Test:

- Uses a shear box1 split horizontally into two halves.

- A normal load is applied vertically, and one half of the box is moved horizontally until failure.

- Simpler apparatus, easy to operate.

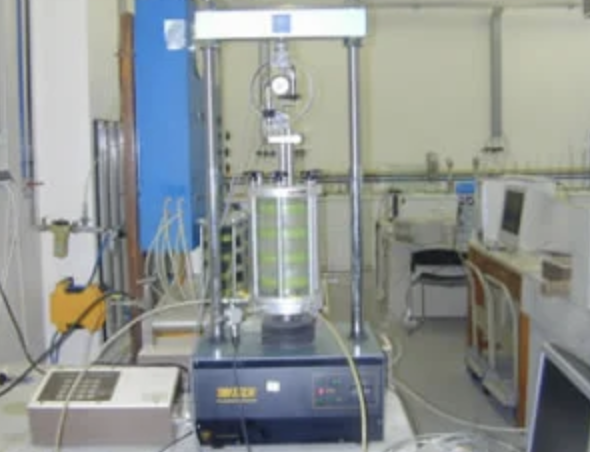

Triaxial Test:

- Uses a cylindrical soil specimen2 enclosed in a rubber membrane, placed in a triaxial chamber3.

- Confined with fluid pressure and loaded axially through a piston.

- More complex equipment, but provides more detailed control and data.

| Feature | Direct Shear | Triaxial Test |

|---|---|---|

| Sample Shape | Rectangular or square | Cylindrical |

| Loading Mechanism | Horizontal shearing | Vertical axial loading |

| Complexity | Simple | Advanced |

Control of Drainage Conditions

Another key difference is the ability to simulate real-world drainage conditions4—a critical factor in soil strength behavior.

Direct Shear Test:

- Limited control over drainage.

- Can be run as drained or undrained, but pore pressure is not measured5.

- Less suitable for saturated or cohesive soils where pore pressure plays a major role.

Triaxial Test:

- Excellent control of drainage and pore pressure.

- Can simulate drained, undrained, or consolidated-undrained (CU) conditions.

- Pore pressure can be measured directly6, allowing for effective stress analysis.

| Condition | Direct Shear | Triaxial Test |

|---|---|---|

| Drained Control | Limited | Precise |

| Pore Pressure Measurement | No | Yes |

| Effective Stress Analysis | No | Yes |

This makes the triaxial test far more versatile and accurate for clay behavior and long-term stability analysis.

Stress Distribution and Failure Plane

How stress is applied and how the soil fails are fundamentally different between the two tests.

Direct Shear Test:

- Applies non-uniform stress7 due to boundary effects.

- The failure plane is predefined, occurring along the interface between the box halves.

- May not reflect natural failure surfaces in the field.

Triaxial Test:

- Provides uniform stress distribution8 in all directions (except axial).

- Failure plane develops naturally within the specimen.

- More representative of actual stress paths and field failures.

| Aspect | Direct Shear | Triaxial Test |

|---|---|---|

| Stress Distribution | Non-uniform | Uniform (confining) |

| Failure Plane | Forced/predefined | Emergent/natural |

| Realism | Moderate | High |

Triaxial testing offers better simulation of real-life soil behavior under loading.

Data Accuracy and Application

Ultimately, the value of a test comes down to the quality of its results and how well they apply to real-world problems.

Direct Shear Test:

- Provides quick estimates of shear strength parameters (cohesion and friction angle).

- Ideal for granular soils and preliminary investigations.

- Lower accuracy for effective stress analysis.

Triaxial Test:

- Delivers more reliable, comprehensive data.

- Suitable for advanced design, slope stability, embankments, and foundations.

- Can be used for both total and effective stress analysis.

| Use Case | Direct Shear | Triaxial Test |

|---|---|---|

| Preliminary soil profiling | ✅ | ✅ |

| Saturated clay analysis | ❌ | ✅ |

| Slope/retaining wall design | ⚠️ (basic only) | ✅ |

| Effective stress modeling | ❌ | ✅ |

Choose the method based on the soil type, project complexity, and desired accuracy.

Conclusion

While both the Direct Shear and Triaxial tests evaluate soil strength, they differ greatly in precision, control, and applicability. Use the Direct Shear test for quick, low-cost assessments of cohesionless soils, and turn to the Triaxial test for critical designs where stress history, drainage, and effective stress matter. The right choice leads to safer designs and better-grounded engineering decisions.

-

Understanding the shear box’s role can enhance your knowledge of soil mechanics and testing methods. ↩

-

Exploring this topic will give you insights into advanced soil testing techniques and their applications. ↩

-

Learning about the triaxial chamber can deepen your understanding of soil behavior under different conditions. ↩

-

Understanding drainage conditions is essential for accurate soil strength analysis and effective engineering solutions. ↩

-

Exploring this topic helps clarify the limitations of direct shear tests in soil mechanics and their implications. ↩

-

Learning about pore pressure measurement enhances knowledge of soil behavior under different conditions, crucial for geotechnical engineering. ↩

-

Understanding non-uniform stress is crucial for interpreting soil behavior under load, making this resource valuable for engineers and geologists. ↩

-

Exploring uniform stress distribution helps in grasping how soils respond to loads, essential for effective engineering solutions. ↩