What Is the Soil Sample for Triaxial Test?

The triaxial test is a standard laboratory method used to determine the strength and deformation characteristics of soil under controlled stress conditions. At the heart of this test is the soil sample—a carefully prepared, cylindrical specimen that represents in-situ ground conditions. Understanding the size, preparation, and types of soils used is essential for obtaining reliable and meaningful results.

Purpose of the Soil Sample in Triaxial Testing

The soil sample1 in a triaxial test serves as a model of in-ground soil behavior. It allows engineers to simulate and study how the soil will perform when subjected to:

- Confining pressure, mimicking soil layers in the field.

- Axial load, representing structural or environmental forces.

- Pore water pressure changes, crucial in evaluating drainage and failure mechanisms.

The sample must be representative of the natural soil conditions2 in terms of moisture content, density, structure, and layering. This ensures that the laboratory results can be confidently applied to foundation design3, slope stability, and soil-structure interaction studies.

Standard Size and Shape of Triaxial Test Samples

Triaxial test samples are typically cylindrical, chosen for their symmetry and ability to withstand evenly applied stresses during testing.

Standard Dimensions

| Sample Diameter (mm) | Sample Height (mm) | Height-to-Diameter Ratio (H/D) |

|---|---|---|

| 38 | 76 | 2 |

| 50 | 100 | 2 |

| 100 | 200 | 2 |

The most commonly used sample is 38 mm in diameter and 76 mm in height, maintaining a height-to-diameter ratio (H/D) of 2:1 to promote uniform stress distribution and minimize end friction.

This standard size ensures consistency in:

- Stress path application

- Strain measurements

- Failure analysis

The cylindrical shape is also compatible with triaxial cell equipment and latex membranes, which prevent water leakage during testing.

How Soil Samples Are Prepared for Testing

Proper sample preparation is critical for reliable triaxial test results. The goal is to create a uniform, undisturbed specimen4 that reflects actual site conditions.

Steps in Sample Preparation

-

Sampling

- Undisturbed samples are obtained using thin-walled Shelby tubes5, block sampling, or piston samplers from boreholes.

- Disturbed samples are remolded in the lab at controlled moisture and density.

-

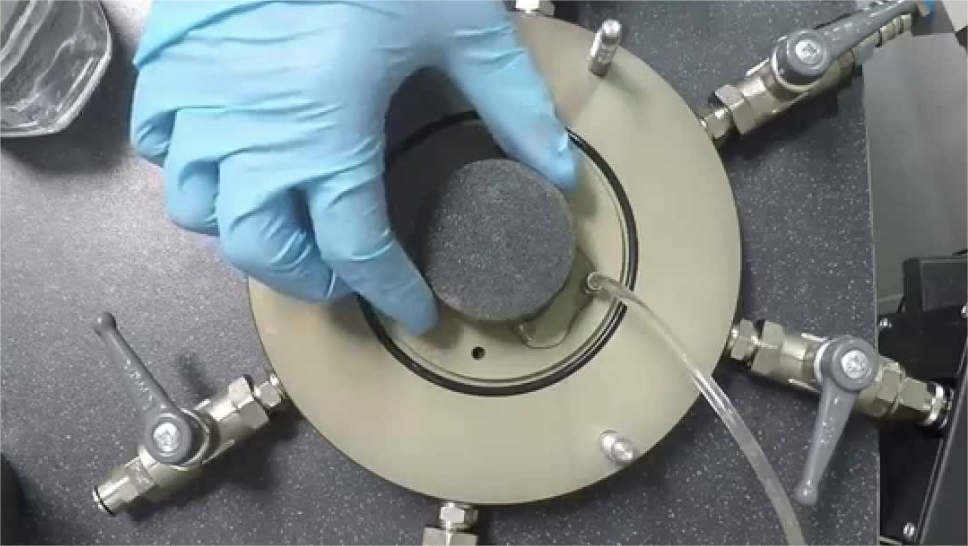

Trimming and Shaping

- Samples are cut to precise dimensions using trimming tools.

- Ends are trimmed flat to ensure even stress distribution.

-

Weighing and Moisture Measurement

- The initial moisture content and mass are recorded.

- The density and void ratio are calculated.

-

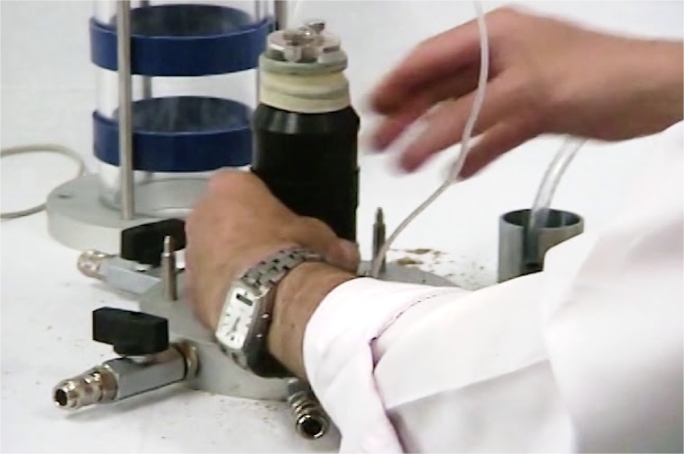

Membrane Placement

- A latex membrane is fitted over the sample to prevent water flow and maintain shape during testing.

-

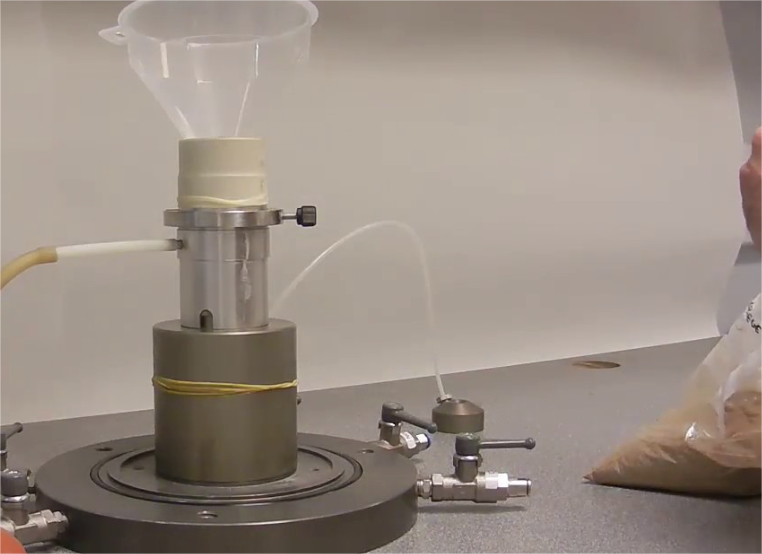

Saturation and Consolidation (if needed)

- In consolidated undrained (CU)6 or drained (CD) tests, samples are saturated with water and consolidated under confining pressure before axial loading.

Sample Preparation Summary Table

| Task | Purpose |

|---|---|

| Trimming | Achieve standard size and flat ends |

| Membrane application | Prevent leakage and maintain confinement |

| Moisture measurement | Ensure accurate strength analysis |

| Saturation | Replicate field saturation conditions |

| Consolidation | Simulate in-situ stress state |

Proper preparation helps eliminate variables that may otherwise affect strain rate, pore pressure buildup, and failure modes.

Types of Soil Suitable for Triaxial Tests

Triaxial testing is highly versatile7 and can be used for a wide range of cohesive and granular soils8, including both natural and engineered materials.

Common Soil Types Used

| Soil Type | Typical Behavior | Test Objective |

|---|---|---|

| Soft Clay | Plastic deformation, low strength | Evaluate consolidation and pore pressure |

| Stiff Clay | Brittle failure, moderate strength | Assess peak and residual strength |

| Silty Soils | Moderate compressibility | Examine drainage behavior |

| Loose Sand | Dilation, low friction angle | Study liquefaction potential |

| Dense Sand | Brittle failure, high strength | Determine effective stress parameters |

| Gravels | Needs larger samples | Evaluate shear resistance under large loads |

Unsuitable Soils

- Highly organic soils (e.g., peat) may be too compressible and variable9.

- Soils with large particles (>20% gravel) require larger triaxial setups.

Testing is particularly effective for soils used in embankments, foundations, retaining structures, and subgrades where understanding strength and stability is crucial.

Conclusion

The soil sample in a triaxial test is a critical component that determines the accuracy, reliability, and applicability of the test results. From proper sizing and shaping to careful preparation and selection of soil type, each step plays a vital role in simulating real-world behavior under stress. Whether testing clays for consolidation or sands for liquefaction, the triaxial soil sample provides the insights needed to design safe and resilient infrastructure.

-

Understanding the role of soil samples in triaxial tests is crucial for accurate engineering assessments and designs. ↩

-

Exploring natural soil conditions helps engineers ensure their designs are safe and effective in real-world scenarios. ↩

-

Learning about foundation design practices can enhance your knowledge of safe and effective construction methods. ↩

-

Understanding the significance of a uniform, undisturbed specimen is essential for accurate triaxial test results. Explore this link for in-depth insights. ↩

-

Learn about the application of thin-walled Shelby tubes in obtaining undisturbed soil samples, crucial for reliable testing outcomes. ↩

-

Discover the principles and importance of the CU test in soil mechanics, vital for understanding soil behavior under stress. ↩

-

Explore how highly versatile triaxial testing can be applied across various soil types for effective engineering solutions. ↩

-

Understanding cohesive and granular soils is essential for effective soil testing and construction practices. ↩

-

Learn about the challenges posed by compressible and variable soils in engineering projects and how to address them. ↩